Process Analytical Technology (PAT) is reshaping cultivated meat production by embedding real-time quality control into manufacturing. Instead of relying on end-product testing, PAT ensures consistent quality throughout production by continuously monitoring key parameters like pH, dissolved oxygen, glucose, and viable cell density. This approach reduces contamination risks, improves efficiency, and aligns with regulatory requirements for consistent product quality.

Key takeaways:

- Real-time monitoring: Sensors track critical parameters without manual sampling, ensuring sterility and reducing costs.

- Automated control: Feedback systems adjust conditions instantly to maintain optimal environments for cell growth.

- Batch consistency: Minimises variability, a common issue in traditional processes where yields can fluctuate by 50%.

- Advanced tools: Technologies like Raman spectroscopy and Memosens sensors enhance precision and scalability.

- Regulatory compliance: Meets FDA and EMA standards for process verification, streamlining approval processes.

Process Analytical Technology in Biomanufacturing

PAT Tools and Techniques for Cultivated Meat

Process Analytical Technology (PAT) now combines traditional sensors with cutting-edge analytical methods to deliver continuous, real-time insights into bioreactor conditions. Together, these tools provide a detailed and uninterrupted view of what's happening inside bioreactors.

Let’s explore the key components of these integrated systems, starting with real-time monitoring sensors.

Real-Time Monitoring Sensors

At the heart of any PAT system are physical sensors, which play a critical role in maintaining stable conditions within bioreactors. These sensors continuously measure pH, dissolved oxygen (DO), temperature, flow rate, and stirrer speed throughout the entire cultivation process [5]. Such parameters are essential for creating an environment where cells can thrive.

One major leap forward is the use of Viable Cell Density (VCD) sensors, which surpass traditional cell counting methods. Technologies like the OUSBT66 absorption sensor and capacitance-based dielectric spectroscopy specifically monitor living cells, ignoring dead ones [3][6]. This focus ensures consistency in cell growth and helps maintain batch uniformity - key factors for productive cell cultivation.

Digital sensor technologies have also revolutionised measurement accuracy in challenging bioreactor environments. Memosens technology, for example, uses non-contact inductive coupling to provide reliable readings even in moisture-heavy conditions. It stores calibration data directly within the sensor head, enabling quick "plug and play" replacements and minimising downtime [3]. For temperature monitoring, in-line RTD sensors such as the TrustSens TM371 are designed to detect failures instantly, reducing the risk of non-conformities [3].

Advanced Analytical Methods

Beyond physical sensors, advanced analytical methods enhance process control and provide deeper insights.

Raman spectroscopy has emerged as one of the most powerful tools in the PAT arsenal. This in-line optical sensor captures a "molecular fingerprint" of the culture environment, enabling simultaneous monitoring of key components like glucose, lactate, glutamine, ammonia, and amino acids [3][5]. Unlike infrared methods, Raman spectroscopy is minimally affected by water, making it especially suitable for aqueous cell cultures [5]. For example, in a T-cell immunotherapy model relevant to cultivated meat production, Raman chemometric models demonstrated correlation coefficients of R = 0.987 for glucose and R = 0.986 for lactate [5].

"Raman spectroscopy is not a plug and read optical sensor technology... the spectroscopic data often needs to be modelled using multivariate analysis approaches... to extract the maximum amount of relevant information." - Marc-Olivier Baradez et al. [5]

For a simpler and more cost-effective alternative, refractometry-based PAT systems are gaining traction. The Ranger RI system, for instance, uses refractive index (RI) profiling to calculate a Process Trend Index (PTI) and Metabolic Rate Index (MRI). These indices track changes in cell metabolism and culture composition [6]. A 2023 study published in Nature demonstrated that integrating this system with HEK293T cell cultures led to a 1.8-fold increase in metabolic activity, achieved through pH control strategies guided by MRI data [6].

However, using these advanced tools requires precision. For example, Raman spectroscopy relies on complex chemometric modelling techniques, such as Partial Least Squares or Artificial Neural Networks, to translate raw spectral data into actionable insights [5].

For cultivated meat producers seeking PAT equipment, platforms like Cellbase connect users with verified suppliers offering sensors, spectroscopy systems, and analytical tools tailored to the specific needs of cultivated meat production.

How to Implement PAT for Batch Consistency

PAT Implementation Challenges and Solutions in Cultivated Meat Production

This section dives into the practical steps for using PAT (Process Analytical Technology) to ensure consistent production of cultivated meat. While PAT involves advanced sensors and analytical tools, its true value lies in turning data into actionable insights. Success depends on seamlessly integrating these tools with bioreactor systems and data management platforms.

The starting point is identifying Critical Quality Attributes (CQAs) and Critical Process Parameters (CPPs). For cultivated meat, these typically include factors like pH, dissolved oxygen, temperature, viable cell density, and metabolites such as glucose and lactate [3][4]. Once identified, the next step is moving from traditional lab analyses to inline sensors that provide continuous, around-the-clock monitoring without compromising sterility [3]. Below, we’ll explore how automated feedback, sensor integration, and overcoming common challenges can streamline PAT implementation.

Automated Feedback Loops

Automated feedback loops are a game-changer for maintaining batch consistency. By linking real-time sensors to bioreactor controls, these loops allow for instant adjustments, such as tweaking feeding rates, gas flow, or agitation speed when parameters drift out of range [2]. For instance, using real-time Raman-based glucose monitoring has been shown to boost titre levels in mammalian cell cultures by 85% [3]. These systems help counteract variability caused by factors like differences in inoculum size or changes in media batches [2].

"The quality of recombinant therapeutic proteins, which cannot be measured online, is closely related to the quality of the production process. Process quality is tightly related to its reproducibility."

– R. Simutis and A. Lübbert, Journal of Biotechnology [2]

Implementing Quality-by-Design (QbD) principles is crucial here. Rather than sticking rigidly to fixed procedures, QbD uses mathematical models to create operational strategies that can adapt to process disturbances [2].

Integrating PAT with Bioreactor Systems

For PAT tools to work effectively, they must integrate smoothly with bioreactor systems. Digital sensor technologies like Memosens are a practical choice, offering reliable performance even in challenging, moisture-heavy environments. These sensors can maintain consistent results from small-scale lab bioreactors to full-scale commercial production [3].

The bigger challenge often lies in managing the data. Disconnected sources - such as sensors, manual logs, and LIMS systems - can create inefficiencies. Centralising all data into one digital platform ensures a "single source of truth", enabling advanced analysis like multivariate data analysis and Principal Component Analysis (PCA). These techniques can quickly pinpoint outliers and identify which process variables drive inconsistencies [1][4].

A great example comes from Aleph Farms, which in 2024 and 2025 used BioRaptor's AI-driven platform to centralise and analyse vast datasets from their upstream processes. Led by Sagit Shalel-Levanon, the team combined data from pH, dissolved oxygen, glucose, and lactate sensors to uncover complex interactions between process inputs. This allowed them to turn raw data into actionable insights in seconds, speeding up the development of scalable production systems [4].

"Our team's scientific expertise in design of experiment (DoE) methodology and statistical analysis, complemented by BioRaptor's AI-driven solution, allow us to better understand the interactions between various process inputs and conditions. With the large data we generate, this capability accelerates the development of robust and scalable processes for cultivated meat."

– Sagit Shalel-Levanon, Senior Director of Process Development, Aleph Farms [4]

For producers seeking compatible tools, platforms like Cellbase offer a marketplace connecting buyers with verified suppliers of sensors, control systems, and analytical tools tailored for cultivated meat production.

Once integration is in place, addressing recurring challenges is essential for long-term success.

Common Implementation Challenges and Solutions

Cost and complexity often stand in the way of adopting PAT. Advanced techniques like Raman spectroscopy require significant investment and expertise [2]. Scaling up can also pose problems - tools that work in the lab may falter during full-scale production if not properly validated [3]. The solution? Choose equipment that meets both Life Science standards (ASME BPE) and Food & Beverage standards (3-A, EHEDG) from the start. This ensures compatibility as production scales [3].

Inline sensors are particularly valuable for maintaining sterility and providing uninterrupted data. Traditional offline analyses not only risk contamination but also increase costs [3].

Automating data collection and analysis can simplify technical complexity, cutting plant engineering costs and time by up to 30% [3]. Self-calibrating sensors, such as automated RTD temperature sensors, further reduce manual intervention, eliminating errors and undetected failures [3].

Regulatory compliance is another challenge, but PAT can actually make meeting these requirements easier. Continued Process Verification (CPV), now expected by both the FDA and EMA, is streamlined with automated software that tracks process capabilities (Cpk and Ppk) and monitors parameters against control limits [1].

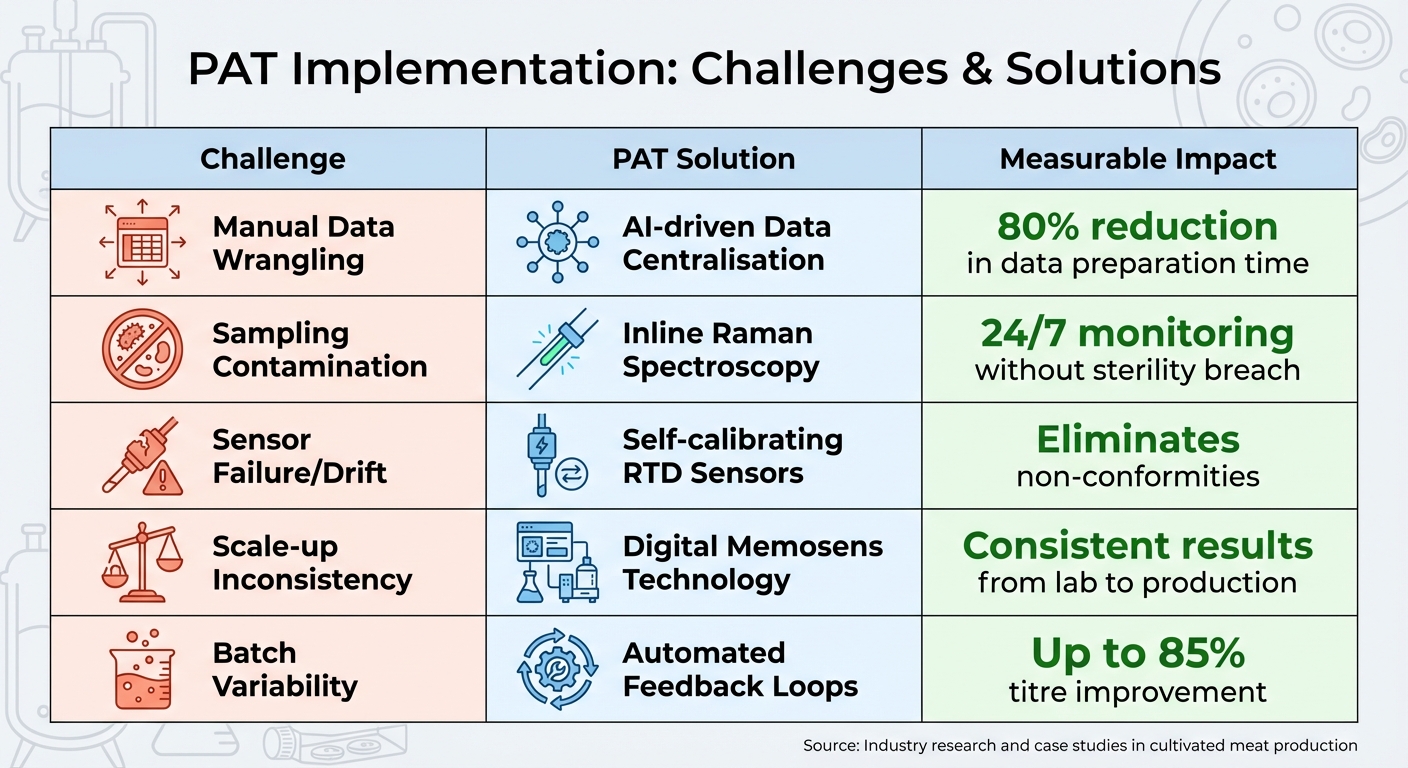

| Challenge | PAT Solution | Measurable Impact |

|---|---|---|

| Manual Data Wrangling | AI-driven Data Centralisation | 80% reduction in data preparation time [1] |

| Sampling Contamination | Inline Raman Spectroscopy | 24/7 monitoring without sterility breach [3] |

| Sensor Failure/Drift | Self-calibrating RTD Sensors | Eliminates non-conformities [3] |

| Scale-up Inconsistency | Digital Memosens Technology | Consistent results from lab to production [3] |

| Batch Variability | Automated Feedback Loops | Up to 85% titre improvement [3] |

To ease adoption, start with a pilot on a single bioreactor. This allows teams to validate the technology and build expertise before scaling up. By addressing these challenges head-on, producers can achieve the batch consistency needed for scalable cultivated meat production.

sbb-itb-ffee270

PAT Applications in Cultivated Meat Production

Process Analytical Technology (PAT) is proving its worth in cultivated meat production. Tools like Raman spectroscopy and advanced sensors are helping to ensure consistent batch quality by maintaining the precise conditions needed for reproducible results. Let’s take a closer look at how these technologies are making a real difference.

Using Raman Spectroscopy to Optimise Cell Culture

Raman spectroscopy is a powerful tool for maintaining stable conditions in cell culture through precise, real-time feedback. Back in April 2022, researchers from Sartorius Stedim Biotech and Reutlingen University showcased this by integrating an in-line Raman flow cell into the cell-free harvest stream of a CHO cell perfusion process. Using an OPLS model, they established a feedback loop that kept glucose levels steady at 4 g/L and 1.5 g/L, with only ±0.4 g/L variability [8][9].

This stability had a direct impact on product quality. By maintaining glucose levels around 2 g/L, glycation in protein products was reduced from roughly 9% to 4% [7]. Compare this with traditional off-line sampling, which typically happens every 24 hours. Raman sensors, on the other hand, deliver updates every few minutes, enabling tighter control and avoiding the "feast-famine" cycles that can disrupt batch consistency [7].

"Raman spectroscopy has been widely adopted in biomanufacturing as a multipurpose analytical technique for real-time monitoring of cell culture performance parameters, such as glucose, glutamine, glutamate, lactate, viable cell density (VCD) and product titre." – Alexander Graf et al., Sartorius Stedim Biotech [7]

This technology’s scalability is another major advantage. In another study from April 2022, a prototype Raman flow cell was tested in a 250 mL Ambr® mini bioreactor system. By using automated design of experiments (DoE) and spiking samples with glucose, lactate, and glutamine, researchers created calibration models that could be scaled up to 2,000 L single-use bioreactors [7].

While Raman spectroscopy is a standout tool, it’s not the only technology making waves in cultivated meat production. Other sensors are also stepping up to improve bioprocess monitoring.

Sensor Technology for Bioprocess Monitoring

In addition to Raman spectroscopy, other sensor systems are playing key roles in real-time monitoring. Bio-capacitance sensors, such as the BioPAT® Viamass, provide continuous in-line measurements of viable cell density (VCD). This allows for automated cell bleeding, ensuring steady-state conditions in perfusion systems [8][9].

Digital tools like Memosens are also crucial. They monitor parameters like pH and dissolved oxygen, delivering reliable results whether in the lab or at commercial scale [3]. Meanwhile, self-calibrating RTD temperature sensors eliminate the risk of unnoticed failures, ensuring process safety without the need for manual checks [3].

The Cell and Gene Therapy Catapult has demonstrated the value of integrated sensor systems in T-cell bioprocessing. By using in-line Raman optical sensors, they achieved correlation coefficients of 0.987 for glucose and 0.986 for lactate [5]. Damian Marshall, Director of New Product Development at the organisation, highlighted the benefits:

"The ability to measure these key parameters using an in-line Raman optical sensor makes it possible to have immediate feedback on process performance. This could help significantly improve cell therapy bioprocessing by allowing proactive decision-making based on real-time process data" [5]

For cultivated meat producers looking to adopt these technologies, platforms like Cellbase connect them with verified suppliers of Raman systems, bio-capacitance sensors, and other PAT tools tailored for this industry.

Future Developments in PAT for Cultivated Meat

The evolution of Process Analytical Technology (PAT) is reshaping cultivated meat production, focusing on greater consistency and scalability. At the heart of this progress are artificial intelligence (AI) and machine learning, which are driving a shift towards autonomous, data-driven control systems. Meanwhile, innovative scaling approaches are tackling the challenges of commercial-scale manufacturing, paving the way for more efficient production.

AI and Machine Learning for Process Control

AI and machine learning are transforming how cultivated meat processes are monitored and controlled. Instead of merely reacting to issues, these technologies now offer predictive insights. For instance, machine learning models can flag process deviations or microbial contamination up to 200 hours earlier than traditional methods [6]. This early detection is critical for ensuring batch consistency and avoiding costly production setbacks.

One key development is the use of soft sensors. These are essentially software models that combine sensor data with statistical tools to estimate variables that are otherwise difficult to measure, like cell viability. By integrating data from hardware sensors - such as Raman spectroscopy - with advanced statistical techniques like Artificial Neural Networks (ANN) and Partial Least Squares (PLS), these models provide a deeper understanding of the process [5][6].

Between 2023 and 2025, Oxford Biomedica showcased the potential of these technologies in lentiviral vector production. Using the Ranger Refractive Index PAT system paired with machine learning, they developed an autonomous pH control strategy. This system adjusted in real time based on metabolic rate index (MRI) data, leading to a 1.8-fold increase in metabolic activity compared to unoptimised methods. It also uncovered previously unnoticed links between pH levels and oxygen availability [6].

Another exciting advancement is the rise of digital twins. These virtual models allow manufacturers to simulate and test key process parameters before actual production begins [10]. Biomatter, a biotech company, has taken this concept further by using proprietary machine-learning algorithms to design entirely new enzymes. As CEO Laurynas Karpus explained in October 2025:

"Our AI can then design a completely new active site and enzyme structure with a completely novel mechanism" [10].

The move towards autonomous process control is especially noteworthy. Emerging PAT systems now rely on adaptive logic, dynamically adjusting bioreactor setpoints in real time based on metabolic activity data. This flexibility is essential for managing the natural variability that occurs between production batches, replacing rigid, pre-set protocols with a more responsive approach [6].

Adapting PAT for Commercial-Scale Production

While AI enhances predictive capabilities, scaling these technologies for commercial use presents distinct challenges that require practical solutions.

One major issue is batch-to-batch reproducibility. Current fermentation processes often show significant variability, with product concentration patterns deviating by up to 50% between runs [2]. Such inconsistencies are a major obstacle to achieving the reliability needed for large-scale production.

Another challenge is ensuring sensor consistency across different production scales. Digital sensors like Memosens, which monitor pH and dissolved oxygen, must deliver reliable data whether they’re used in small laboratory bioreactors or large-scale manufacturing facilities. Standardising these instruments across all scales can streamline process transfers and cut plant engineering costs and timelines by up to 30% [3].

Cost is another barrier to scaling. High operational expenses for offline analyses and advanced equipment can limit commercial viability [11][3]. To address this, some companies are exploring more economical bioreactor materials to reduce capital costs [11]. Additionally, media recycling strategies, such as tangential flow filtration, are being implemented to offset the high costs of cell culture media [11].

For businesses looking to adopt these advanced PAT systems, platforms like Cellbase provide access to trusted suppliers of AI-powered sensors, refractometry systems, and other cutting-edge technologies tailored for cultivated meat production.

Conclusion

Process Analytical Technology (PAT) is reshaping how consistency is managed in cultivated meat production. Instead of waiting until the end of production to test quality, PAT integrates real-time monitoring and automated adjustments directly into the process. This shift tackles one of the industry's toughest hurdles: the inherent variability of biological systems. As discussed earlier, each component of PAT plays a role in creating a more reliable and predictable production framework.

Technologies like Raman spectroscopy and refractometry provide continuous, real-time insights into cell metabolism, eliminating the need for manual sampling. This not only reduces the risks of contamination from open sampling but also closes the "blind spots" between periodic lab tests [3][5]. When combined with automated feedback systems, these tools can make real-time adjustments, such as adding nutrients or fine-tuning pH levels, ensuring optimal conditions are maintained throughout the cultivation process.

The commercial advantages of these innovations are substantial. For example, real-time glucose control using Raman technology has been shown to increase product yield by 85%, while pH optimisation through refractometry enhances metabolic activity by 1.8 times [3][6]. As the cultivated meat sector moves towards its anticipated 30% share of global meat consumption by 2040, such efficiency improvements are crucial for keeping production economically viable [3].

Standardised digital sensors, such as Memosens, further streamline the transition from lab-scale to commercial production by ensuring consistent measurements across different bioreactor sizes. These tools can cut engineering costs and timelines by as much as 30% [3]. For producers aiming to adopt these advanced systems, resources like Cellbase connect them with trusted suppliers of PAT equipment tailored specifically for cultivated meat.

AI and machine learning have also entered the scene, enabling predictive and autonomous process control. These technologies allow systems to adapt to the unique characteristics of each batch. As Thomas Williams and his team highlighted:

"Process control and intervention using this novel refractometry-based PAT system has the potential to facilitate the fine tuning and rapid optimisation of the production environment and enable adaptive process control for enhanced process performance and robustness" [6].

This ability to adapt will be especially vital as the industry scales up from research-level operations to full commercial manufacturing. These advancements underscore the essential role of PAT in ensuring both quality and scalability in the cultivated meat industry.

FAQs

How does Process Analytical Technology (PAT) ensure consistent quality in cultivated meat production?

Process Analytical Technology (PAT) plays a key role in maintaining batch consistency in cultivated meat production by enabling real-time monitoring and control of essential bioprocess parameters. With tools like spectroscopic and electrochemical sensors, PAT keeps a close eye on critical factors such as pH, oxygen levels, temperature, and nutrient concentrations inside bioreactors. This constant monitoring allows for quick adjustments to ensure conditions remain optimal throughout the production process.

By offering a clear view of the cellular environment, PAT helps reduce variability between batches, cuts down on waste, and improves overall efficiency. It ensures that every batch meets the same high-quality standards. When paired with AI-driven systems, PAT takes precision to the next level, simplifying operations and supporting the production of safe, consistent cultivated meat.

What advantages does Raman spectroscopy provide for monitoring bioreactor conditions in cultivated meat production?

Raman spectroscopy serves as an invaluable Process Analytical Technology (PAT) for cultivated meat production, offering real-time, non-invasive monitoring of bioreactor conditions. By continuously gathering data, it establishes a connection between process parameters and critical quality attributes, ensuring each batch meets consistent, high-quality standards.

This technique enables the simultaneous tracking of essential factors like cell density, viability, and metabolite levels, delivering crucial insights into the bioprocess. These real-time readings allow for adaptive process control, boosting productivity while minimising potential risks. Moreover, Raman spectroscopy ensures stable growth conditions throughout production, streamlining the cultivation process for optimal results.

How do AI and machine learning improve process control in cultivated meat production?

AI and machine learning are transforming process control in cultivated meat production, offering precise monitoring, cutting down on waste, and maintaining consistent quality. These technologies process data from sensors that monitor critical factors like pH, oxygen levels, temperature, and cell growth. This allows producers to fine-tune production conditions in real time.

Machine learning models can also anticipate potential problems, such as contamination or irregularities in cell growth, enabling swift corrective measures. What’s more, these systems get smarter over time by retraining with new data, improving their precision and dependability. AI-powered Process Analytical Technology (PAT) systems take things a step further by delivering real-time insights into cell culture metabolic activity, which helps ensure batch consistency and adherence to regulatory requirements.

By integrating AI and machine learning, cultivated meat producers can boost efficiency, scale production more effectively, and enhance product safety. This progress is helping to shape a future of more sustainable food production.