In cultivated meat production, sensors and automated systems are transforming how bioreactors are managed. By tracking critical factors like pH, dissolved oxygen, glucose, and temperature in real time, these technologies ensure consistent cell growth and minimise risks like contamination or batch failure. Here's what you need to know:

-

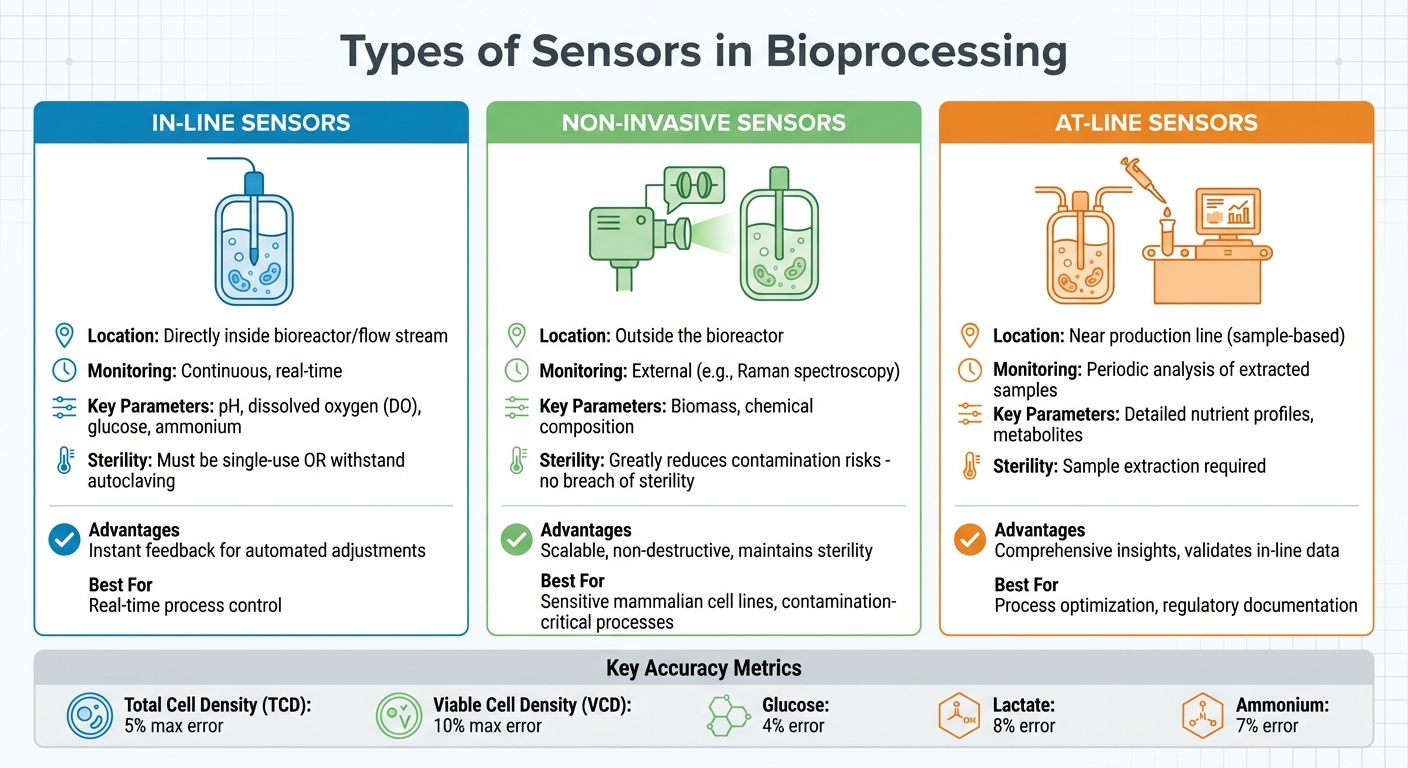

Types of Sensors:

- In-line: Directly monitor parameters inside the bioreactor for real-time adjustments.

- Non-invasive: Use external tools like Raman spectroscopy to maintain sterility.

- At-line: Analyse samples near production for detailed insights.

- Key Metrics: Temperature, pH, dissolved oxygen, glucose, lactate, and ammonium levels are vital for process control. Advanced sensors can measure these with high precision, supporting better decision-making.

- Automation Benefits: AI-powered sensors provide instant updates, reduce manual sampling, and optimise nutrient feeding strategies. This improves efficiency and aligns with regulatory standards.

- Scaling Up: Moving from lab-scale to commercial production requires robust sensors that handle larger volumes and complex conditions. Multi-spatial arrays and advanced calibration methods are essential.

This shift to automated, sensor-driven systems is not just about improving efficiency but also about meeting regulatory demands and ensuring product quality at scale. Keep reading to explore sensor integration techniques, maintenance tips, and how AI is shaping the future of bioprocessing.

Bioprocess Automation for PAT with BioProfile FLEX2 plus Seg-Flow

Types of Sensors Used in Bioprocessing

Types of Sensors in Bioprocessing: In-Line, Non-Invasive, and At-Line Comparison

Choosing the right sensors for bioprocessing is all about balancing real-time monitoring, sterility, and the level of detail needed. The three main types - in-line, non-invasive, and at-line - each play a unique role in cultivated meat production. These sensors aim to provide accurate data while minimising contamination risks, ensuring they fit seamlessly into specific bioprocessing needs.

In-Line Sensors

In-line sensors are placed directly inside the bioreactor or flow stream, offering continuous, real-time monitoring of critical parameters like pH, dissolved oxygen (DO), glucose, and ammonium. Since they're immersed in the culture medium, they must either be single-use or robust enough to handle sterilisation methods such as autoclaving to maintain a sterile environment. In cases where direct immersion isn't feasible, non-invasive sensors step in as a sterile alternative.

Non-Invasive Sensors

Non-invasive sensors operate from outside the bioreactor, using tools like Raman spectroscopy to monitor culture conditions without breaching sterility. This method greatly reduces contamination risks, which is especially important when working with sensitive mammalian cell lines in cultivated meat production. For instance, All-in-One Process Raman solutions allow scalable, non-destructive tracking of biomass and chemical composition [3]. While they excel in maintaining sterility, non-invasive sensors may not match the precision of in-line options for certain parameters, making them ideal for scenarios where avoiding contamination takes precedence. When more detailed analysis is needed, at-line sensors provide a valuable complement.

At-Line Sensors

At-line sensors are used to analyse samples taken near the production line. These sensors are particularly effective for validating in-line data or when detailed analysis outweighs the need for immediate results. While in-line sensors offer instant feedback for automated adjustments, at-line methods take longer but deliver more comprehensive insights into nutrient profiles and metabolites [1]. This makes them especially useful for process optimisation and meeting regulatory requirements, where detailed documentation is crucial.

Key Parameters for Real-Time Monitoring

Selecting Process-Specific Variables

To monitor processes effectively, it's essential to define your goals and choose the right parameters. Common variables like temperature, pH, and dissolved oxygen (DO) help maintain stable conditions, while Critical Process Parameters (CPPs) - such as glucose, lactate, and ammonium concentrations - offer a direct window into the metabolic state and nutrient levels [4].

Key Performance Indicators (KPIs), including total cell density (TCD) and viable cell density (VCD), are equally crucial. These indicators track cell growth and help determine the best time for actions like harvesting or shifting media [4]. For example, Raman spectroscopy can estimate TCD with a maximum error of 5% and VCD with an error of 10%. Similarly, real-time metabolite measurements show errors of approximately 4% for glucose, 8% for lactate, and 7% for ammonium [4]. This level of precision demonstrates the advantage of real-time monitoring over traditional manual sampling methods [1].

Another benefit of automated in-line monitoring is its ability to reduce manual sampling, which significantly lowers the risk of contamination and potential batch failure [1][4]. Real-time data also facilitates automated nutrient control, enabling precise feeding strategies. For instance, maintaining glucose levels above critical thresholds, such as 4 g/L, leads to better yields and consistency [4].

Once the key variables are identified, the next step is ensuring accurate monitoring through proper sensor placement.

Sensor Placement and Accuracy

The placement of sensors is just as important as selecting the right ones. To ensure accurate readings, probes should be fully immersed in the culture medium using standardised adaptors like PG13.5 cable glands [4]. In larger systems, sensor location becomes even more critical, as it ensures the data reflects the entire vessel rather than just a small area [4].

Temperature compensation plays a key role in maintaining accuracy. Measurements of pH and DO are particularly sensitive to temperature changes, which can be addressed using transmitter blades that connect RTD (resistance temperature detector) or thermistor inputs to the control software [3]. This ensures that temperature fluctuations don’t distort readings, helping meet the quality standards required for cultivated meat production.

sbb-itb-ffee270

How to Integrate Sensors with Automated Control Systems

Connecting Sensors to Bioprocess Control Software

The way sensors communicate with your central software depends on the structure of your control system. Traditional Hierarchical Structure Control Systems (HSCS) use a three-layer setup where analogue signals pass through a PLC or DCS. These systems digitise the data before sending it to the central software. While reliable, this approach can lead to bottlenecks.

Many modern cultivated meat facilities are shifting to Fieldbus Control Systems (FCS) and Networked Control Systems (NCS). These systems simplify integration by allowing sensors to connect directly to the central system through a single communication channel [5]. Today’s smart sensors can process data and perform self-diagnostics, eliminating the need for intermediary computing devices [5]. For instance, switching to an FCS for L-asparaginase II fermentation resulted in a 100% increase in output compared to older control methods [5].

When setting up sensors, make sure they comply with digital standards and temperature compensation protocols. Sensors and actuators should be compatible with widely accepted digital standards like Profibus, Foundation Fieldbus, or Ethernet. This ensures easy device replacement and reduces maintenance costs [5]. Specialised bioprocess control software, such as TruBio (powered by Emerson DeltaV), supports scaling and ensures data integrity without requiring manual programming [3].

For sourcing high-quality sensors and components that meet these standards, you can explore verified options on Cellbase, a B2B marketplace tailored to the cultivated meat industry.

With these streamlined systems in place, advanced AI and data analytics can further enhance bioprocess control.

Using AI and Data Analytics

Building on real-time monitoring, AI-driven biosensors are transforming how cultivated meat bioprocessing is managed. In February 2025, The Cultivated B introduced a multi-channel, AI-enabled biosensor system that integrates continuous monitoring with real-time data analytics. This system tracks cell growth and metabolic activity - such as glucose, amino acids, and lactic acid - at picomolar concentrations. The result? Real-time recommendations for media adjustments and control strategies, eliminating the need for manual sampling or physical probes [6][7]. Hamid Noori, Founder and CEO of The Cultivated B, highlighted its impact:

"Our sensor technology for bioreactors accelerates the learning curve of bioprocessing, ensuring high-quality output and exceptional product quality. I am confident this will empower industries to streamline workflows and enable scalable processes through enhanced automation." [6]

To optimise dynamic process adjustments, use multi-channel biosensors capable of detecting molecules at picomolar levels. These sensors provide high-resolution data that AI systems can analyse [6]. Pairing smart sensors with actuators in local closed-loop systems and using fuzzy logic for nutrient optimisation can reduce reliance on central networks [5].

Maintaining and Scaling Sensor Systems

Sensor Calibration and Maintenance

Calibration is the backbone of ensuring accurate readings in cultivated meat production. This process aligns sensor outputs - like those from thermometers, pressure gauges, pH sensors, and dissolved oxygen probes - with established standards. Regular calibration isn't just a good practice; it's essential for meeting GMP requirements and food safety regulations like Regulation (EC) 853/2004 [1]. To achieve this, setting consistent calibration schedules and using automated monitoring systems for data logging are key steps for both compliance and process efficiency.

Automated bioprocess software, coupled with integrated RTDs (resistance temperature detectors), helps maintain precise calibration, even when temperatures fluctuate.

For a more convenient option, single-use sensors are gaining traction. These reduce the need for extensive cleaning and recalibration. For example, systems like the Thermo Scientific DynaDrive can scale from 5 to 5,000 litres while maintaining automation and efficiency [3]. On the other hand, reusable sensors, though requiring more maintenance, may offer durability over time.

Once your calibration and maintenance workflows are solid, scaling these sensor systems for commercial production presents a whole new set of challenges.

Scaling to Commercial Production

When moving to larger-scale production, sensor systems must adapt to address spatial variability. A sensor that works perfectly in a small 50 ml dish might not deliver accurate data in a 2-litre cell bag - or a much larger bioreactor [2]. As bioreactor volumes grow, single-point sensors often fall short in capturing the full complexity of the environment.

To counter this, multi-spatial sensor arrays and advanced thin-film sensors are effective. These systems provide uniform monitoring, with less than 2% variation in performance over a 30-day period [2]. For rocking bioreactors, sensors must also withstand significant mechanical stress. Flexible sensor designs have been tested to survive over 1,498,110 bending cycles before showing signs of wear [2]. Adding protective membranes, like polyethersulfone (PES), can further minimise biofouling and extend sensor life.

Before scaling up, it’s wise to test sensor performance on microfluidic scale-down models. This approach helps identify potential issues early, ensuring smoother transitions to commercial hardware [8]. Additionally, choosing bioprocess controllers that allow seamless data transfer from lab-scale to production-scale setups is critical. Platforms like Emerson DeltaV are designed to maintain data integrity and facilitate the technology transfer process from R&D to full-scale production [3].

Conclusion

Pairing sensors with automated bioprocess systems is revolutionising the production of cultivated meat, taking it from experimental research to large-scale manufacturing. By enabling real-time monitoring of key factors like pH, dissolved oxygen, glucose, and temperature, these systems provide immediate insights into culture conditions. This allows for quick adjustments, reducing the risk of failures and promoting optimal growth. As Giovanni Campolongo, Senior Market Segment Manager at Hamilton Company, puts it:

"Leveraging inline sensors for monitoring and control of process conditions will be essential to realizing successful commercial production" [9].

This synergy supports every stage of production, from fine-tuning processes to adhering to strict regulatory requirements.

Automated systems also minimise manual intervention while generating detailed data logs - an essential component for GMP compliance and UK food safety standards. Advanced controllers, such as the Thermo Scientific DynaDrive, can handle volumes ranging from 5 to 5,000 litres [3], ensuring a smooth transition from lab-scale to commercial-scale operations.

The integration of AI-driven monitoring adds another layer of efficiency. Where traditional methods might take days to identify issues, AI-enabled biosensors provide instant updates on bioreactor conditions [1]. This level of responsiveness is crucial in a sector where production costs have plummeted - from approximately £250,000 per burger in 2000–2001 to just £7.40 by early 2022 [9]. With over 150 companies globally now working on cultivated meat, incorporating efficient sensor systems has shifted from being a luxury to a competitive requirement [9].

As these technologies continue to evolve, platforms like Cellbase play a vital role in helping producers source verified sensors tailored for cultivated meat production. Whether it's calibrating sensors for a pilot bioreactor or implementing advanced arrays for large-scale operations, investing in the right sensor infrastructure is key to ensuring regulatory compliance and operational success.

FAQs

How do non-invasive sensors help maintain sterility in bioprocessing systems?

Non-invasive sensors play a key role in keeping bioprocessing systems sterile by monitoring them without coming into direct contact with the cell culture environment. These sensors are usually positioned outside the bioreactor or rely on microfluidic systems, enabling them to gather real-time data on factors like dissolved oxygen, pH levels, and metabolites - all without breaching the bioreactor.

This method greatly minimises the risk of contamination compared to older, invasive probes. Technologies like optical sensors and AI-powered biosensors take this a step further by improving both process control and data precision while maintaining sterility. Such advancements are critical for protecting the integrity of cultivated meat production systems.

How does AI improve bioprocess control in cultivated meat production?

AI plays a transformative role in improving bioprocess control for cultivated meat, offering precise, efficient, and automated management of production. It achieves this by analysing real-time data collected from sensors monitoring critical parameters like pH, oxygen levels, temperature, and cell growth. With the help of machine learning algorithms, AI processes this data to predict results, spot irregularities, and fine-tune conditions, ensuring consistent quality while minimising waste.

When combined with in-line sensors, AI-driven bioprocess systems can automatically adjust settings to maintain ideal growth conditions, eliminating the need for manual intervention. This approach not only boosts scalability and reliability but also helps meet regulatory requirements, driving forward the commercial viability of cultivated meat production.

How can sensors be scaled effectively for commercial cultivated meat production?

Scaling sensors for producing cultivated meat at a commercial level demands advanced systems capable of precise monitoring and control as production volumes increase. Modern sensor technologies, such as wireless sensors and multi-parameter probes, are engineered to monitor essential variables like pH, dissolved oxygen, glucose levels, and temperature throughout bioreactors. These sensors often come with flexible, embedded designs that allow for real-time, spatially-resolved data collection, ensuring consistent conditions for optimal cell growth.

For large-scale operations, these sensors must work seamlessly with automated feedback systems. This integration enables continuous data logging and real-time adjustments to critical factors such as nutrient supply and oxygen levels. Automation reduces the need for manual intervention, enhances reproducibility, and boosts overall efficiency. Meanwhile, advancements like multiplexed probes and wireless electronics provide a cost-effective way to scale up without compromising on accuracy or reliability. By adopting these technologies, producers can maintain stable processes, ensure consistent product quality, and improve operational efficiency as they expand to commercial-scale production.