Organoleptic testing is critical for cultivated meat to replicate the sensory qualities of conventional meat. Key metrics include:

- Juiciness: Measured using Gas Chromatography-Mass Spectrometry (GC-MS) and moisture loss tests during cooking. Challenges include replicating fat content and moisture retention.

- Tenderness: Evaluated with Texture Profile Analysis (TPA) and Warner-Bratzler Shear Force (WBSF). Cultivated meat shows promise in achieving softer textures.

- Mouthfeel and Texture: Analysed through rheology and scaffold stiffness. Current products lack the fibrous complexity of whole cuts.

- Flavour and Aroma: Techniques like GC-MS and electronic noses identify key compounds, such as those from the Maillard reaction, to mimic meaty flavours.

While cultivated meat struggles with juiciness and flavour complexity, advancements in co-culture systems and flavour-enhancing scaffolds are narrowing the gap with conventional meat.

Key Organoleptic Metrics for Cultivated Meat

Juiciness: Measurement Methods and Findings

Replicating the juiciness of conventional meat in cultivated alternatives has proven tricky. Researchers are tackling this by co-culturing adipocytes (fat cells) with muscle cells or producing separate "fat blocks" rich in lipids. These approaches aim to improve moisture retention and enhance the oily flavour profile that contributes to juiciness [1][9].

To measure juiciness, Gas Chromatography-Mass Spectrometry (GC-MS) is commonly used. This method identifies volatile compounds like nonanal and 2-ethyl-1-hexanol, which are key to the "fatty" mouthfeel and the perception of juiciness [1][3]. Another approach involves cooking meat samples to specific internal temperatures - 65°C, 70°C, and 75°C - and measuring the moisture loss during the process [5]. Researchers have found that increasing adipogenesis not only enhances moisture retention but also generates volatile compounds that mimic the roasted beef aroma [1].

These advancements in juiciness research pave the way for exploring other important textural qualities, such as tenderness.

Tenderness: Assessment and Benchmarks

After juiciness, tenderness stands out as a crucial factor in determining the quality of cultivated meat. Two primary methods are used to evaluate tenderness: Texture Profile Analysis (TPA) and Warner-Bratzler Shear Force (WBSF).

- TPA simulates the chewing process through a double-compression test, measuring aspects like hardness, springiness, cohesiveness, chewiness, and resilience [2].

- WBSF uses a V-notched blade to determine the force needed to shear the meat sample [7][2].

A 2022 study [2] compared cultivated Frankfurt-style sausages with conventional ones. While the hardness levels were similar, the cultivated sausages showed a springiness score of 0.54, close to that of raw chicken (0.61). However, the study noted that cultivated meat tends to have a higher Young's Modulus (a measure of stiffness) compared to conventional processed meat [2].

"The Young's Modulus analysis was the parameter that showed the larger differences... cultured meat prepared Frankfurt sausage, presents a significant higher value than the commercial sausage suggesting that the process to prepare it gives rise to a stiffer product." - Jacobo Paredes et al., Nature [2]

Mouthfeel and Texture Analysis

Achieving the right mouthfeel is essential for consumer satisfaction. Mouthfeel is assessed using rheology, which evaluates the viscoelastic properties of meat by measuring the storage modulus (G') and loss modulus (G'') [2]. This method provides insights into the internal structure and flow behaviour of meat matrices [2]. To get a complete picture, researchers now combine tension, compression, and shear tests, offering a three-dimensional analysis of meat products [8].

One key factor influencing mouthfeel is scaffold stiffness, which plays a major role in shaping the final texture. Studies suggest that scaffolds with a Young's modulus of about 11 kPa are ideal for muscle growth (myogenesis), while those around 3 kPa are better suited for fat growth (adipogenesis) [1]. Additionally, cultivated muscle tissues stiffen when heated to 60°C due to protein denaturation [1].

Cultivated meat often exhibits lower cohesiveness compared to conventional processed meat, meaning it tends to break apart more easily during testing [2]. In contrast, animal meat typically shows higher stiffness in tension than in compression. For instance, animal sausage has a tension-compression asymmetry of 2.41 [8]. These factors significantly influence the overall eating experience.

Flavour and Aroma Profiling in Cultivated Meat

Analytical Methods for Flavour and Aroma

Flavour is one of the most critical qualities when it comes to cultivated meat. To identify the volatile compounds responsible for meaty, musty, and fatty aromas, researchers rely on advanced techniques like Gas Chromatography-Mass Spectrometry (GC-MS) combined with Dynamic Headspace (DHS) Sampling and GC-MS-Olfactometry (GC-MS-O). In these methods, trained assessors sniff the GC effluent, matching chemical peaks to specific aromas [6][10][11].

Another tool, the electronic nose (e-nose), offers rapid aroma fingerprinting. This technology creates a "fingerprint" of aromas, enabling quick comparisons between cultivated and conventional meat [10]. Meanwhile, the electronic tongue (e-tongue) evaluates non-volatile taste components like bitterness, sourness, and umami by measuring electrochemical responses [3]. For water-soluble flavour precursors such as amino acids and sugars - key players in aroma formation during cooking - Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS) is the go-to method [1][11].

In one study, researchers used Principal Component Analysis on GC-MS data to compare cultivated pork fat with conventional fat, capturing 90.0% of the variation between the two samples [6]. This level of detail helps pinpoint where cultivated meat differs and guides efforts to replicate conventional meat flavours more precisely.

These tools do more than identify aromas - they also help scientists zero in on the compounds needed to mimic the flavours of traditional meat.

Key Aromatic Compounds in Cultivated Meat

Using these cutting-edge techniques, researchers have identified specific aromatic compounds crucial for replicating the flavour of conventional meat. Reproducing the complex chemistry of cooked meat is no small task, as cultivated meat often lacks certain flavour precursors that naturally accumulate in animals through their diet or are modified by non-muscle organs [4]. A prime example is the Maillard reaction, which occurs when amino acids and reducing sugars interact at temperatures above 150°C, creating the roasted, meaty aroma that defines cooked beef [10].

"The difference in amino acid profiles between in vitro tissues and traditional meat presents challenges in mimicking the Maillard flavour of traditional meat." - Nature Communications [10]

Sulphur-containing compounds are especially important for authentic meat aromas. Furfuryl mercaptan contributes roasted meat notes, while 3-mercapto-2-pentanone adds meaty and onion-like flavours [10]. Another key compound, 2,5-dimethylpyrazine, delivers roasted beef-like aromas and serves as a marker for successful muscle cell differentiation [1]. Fatty notes, on the other hand, stem from compounds like nonanal and 2-ethyl-1-hexanol, which are by-products of lipid oxidation [1][3].

In December 2023, researchers at KU Leuven demonstrated that grilling differentiated muscle blocks at 180°C for five minutes produced higher levels of 2,5-dimethylpyrazine and benzaldehyde, aligning the cultivated meat's chemical profile more closely with conventional beef [1]. By June 2024, a new breakthrough emerged: researchers developed a "flavour-switchable scaffold" using furfuryl mercaptan bound to a gelatin-based hydrogel. When heated to 150°C, the scaffold released meaty volatiles, creating a flavour profile that, according to Principal Component Analysis, was much closer to conventional beef than standard cultivated meat [10]. Impressively, the scaffold retained 93.8% of its weight over a 14-day cell culture period at 37°C [10].

Sensory evaluation of alternative proteins: A best practices guide

sbb-itb-ffee270

Comparing Cultivated and Conventional Meat

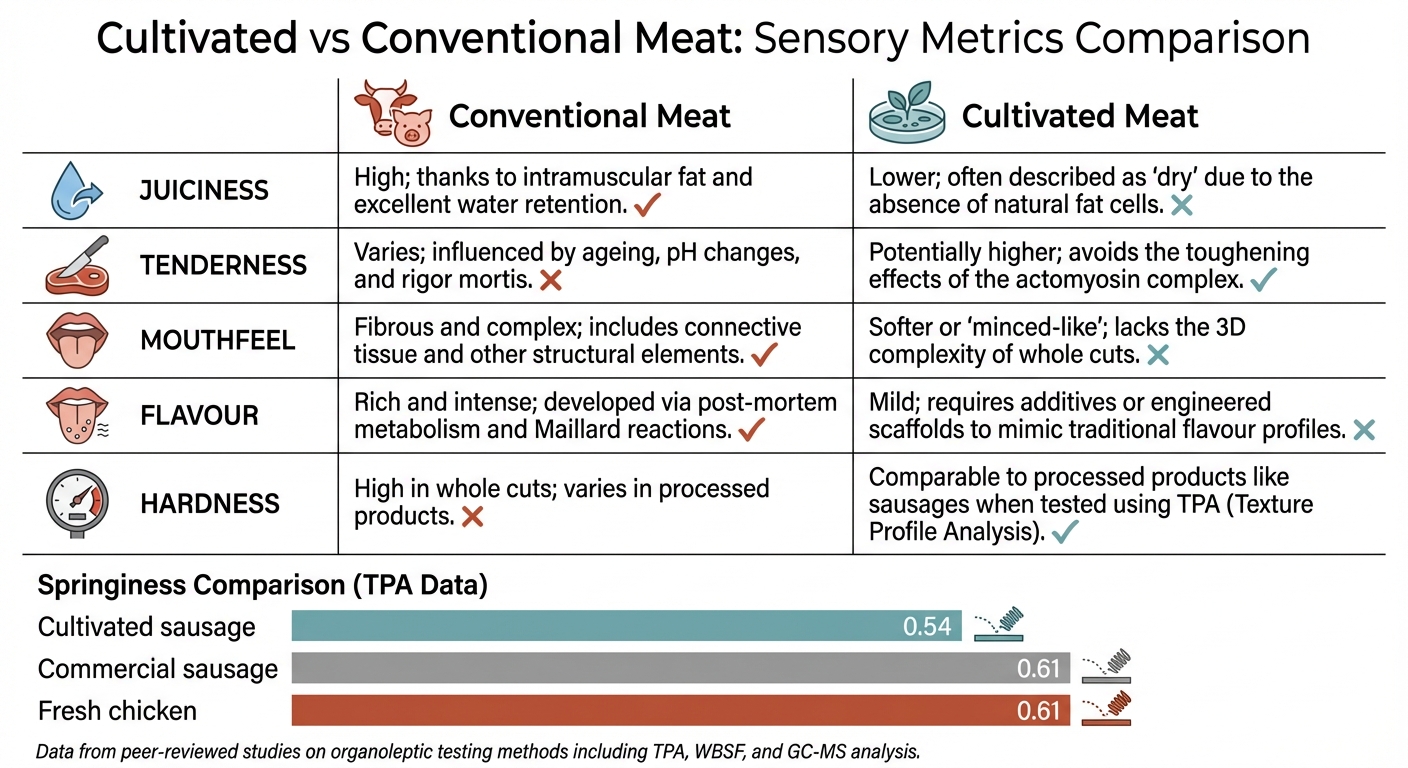

Cultivated vs Conventional Meat: Sensory Metrics Comparison

When it comes to cultivated meat, there are clear hurdles to overcome to match the sensory qualities of conventional meat. Understanding these differences is key to bridging the gap and achieving a similar eating experience. Here's how cultivated meat stacks up against its traditional counterpart across several sensory aspects.

Juiciness remains a significant challenge. Conventional meat benefits from natural intramuscular fat and water-holding capacity, which cultivated meat has yet to replicate effectively [4]. On the other hand, tenderness could be an area where cultivated meat shines. By avoiding the process of rigor mortis and the formation of the actomyosin complex, which toughens traditional meat, cultivated meat may achieve a softer texture. As Lieven Thorrez from KU Leuven explains:

"If rigor mortis would be less strong or no actomyosin complex would be formed, this may have a positive effect on the product quality with respect to tenderness... in comparison to traditional meat" [4].

Mouthfeel and texture are other areas that need refinement. Currently, cultivated meat tends to resemble the soft, minced texture found in processed products rather than the fibrous complexity of whole cuts. For instance, a 2022 study by Biotech Foods S.L. compared a cultivated Frankfurt-style sausage to its commercial counterpart. The cultivated sausage had a springiness value of 0.54, slightly lower than the 0.61 observed in commercial sausages, making it closer in texture to fresh chicken than traditional pork [2]. Additionally, the cultivated version showed higher stiffness (Young's modulus), indicating a need for process improvements to align with consumer preferences [2].

Flavour is perhaps the most noticeable shortcoming. Conventional meat develops its rich, complex taste through post-mortem metabolism and Maillard reactions. In contrast, cultivated meat, unless its muscle cells are highly differentiated, tends to have a milder flavour [4][1][10]. Without these natural flavour-enhancing processes, cultivated meat requires innovative solutions to replicate the intense taste profile of traditional meat.

Sensory Metrics Comparison Table

| Metric | Conventional Meat | Cultivated Meat |

|---|---|---|

| Juiciness | High; thanks to intramuscular fat and excellent water retention [4]. | Lower; often described as "dry" due to the absence of natural fat cells [4]. |

| Tenderness | Varies; influenced by ageing, pH changes, and rigor mortis [4]. | Potentially higher; avoids the toughening effects of the actomyosin complex [4]. |

| Mouthfeel | Fibrous and complex; includes connective tissue and other structural elements [4]. | Softer or "minced-like"; lacks the 3D complexity of whole cuts [4][2]. |

| Flavour | Rich and intense; developed via post-mortem metabolism and Maillard reactions [4]. | Mild; requires additives or engineered scaffolds to mimic traditional flavour profiles [1][10]. |

| Hardness | High in whole cuts; varies in processed products [2]. | Comparable to processed products like sausages when tested using TPA (Texture Profile Analysis) [2]. |

Conclusion

Thorough organoleptic testing plays a crucial role in ensuring cultivated meat meets the expectations of traditional meat consumers [3]. Research consistently highlights sensory similarity as a key factor in gaining consumer acceptance [3]. By combining rigorous testing methods with ongoing advancements, the cultivated meat industry continues to pave the way for its development.

The hurdles, however, are undeniable. Cultivated meat currently lacks the natural post-mortem processes - like the pH drop and rigor mortis - that give traditional meat its distinctive flavour and texture [4]. Despite this, progress is evident. A 2024 study by Pasitka et al. revealed that 67% of participants preferred a hybrid cultivated chicken product over a soy-based alternative, showing that achieving sensory similarity is within reach [3]. Mercedes Vila of Biotech Foods S.L. underscores the importance of these efforts:

"The sensory properties of cultured meat are derived from the molecular characteristics of the product, and as cultured meat is still in its infancy, the study and understanding of its properties is of outmost importance" [2].

Future Directions in Organoleptic Research

Researchers are actively tackling the challenges of flavour and texture. For instance, flavour-switchable scaffolds are being developed to release meaty compounds, like furfuryl mercaptan, when heated to around 150°C. This approach addresses the issue of volatile compound loss during extended culture periods [10].

Texture analysis has also become more advanced. Instead of relying solely on basic hardness tests, scientists now employ methods like Texture Profile Analysis and rheology to replicate the mechanical properties - such as the Young’s modulus and shear modulus - of specific meat cuts like tenderloin or brisket [2]. Co-culture systems, which combine myoblasts, fibroblasts, and adipocytes, are helping to mimic the intricate connective tissue and fat marbling found in whole cuts of meat [4]. Additionally, tools like electronic noses and tongues offer objective ways to compare flavour and taste profiles with those of conventional meat [10].

These breakthroughs underscore the importance of sustained research and innovation in cultivated meat development.

How Cellbase Supports Cultivated Meat R&D

Cellbase simplifies the research process for cultivated meat developers by providing access to specialised tools and materials. From rheometers to GC-MS systems, the platform connects researchers with the analytical instruments needed to measure mechanical properties and sensory outcomes. Cellbase also supplies essential biopolymers like GelMA, fish gelatine, and alginate for scaffold engineering. By streamlining procurement, the platform allows R&D teams to focus on turning cellular innovations into market-ready products.

FAQs

How is the juiciness of cultivated meat made similar to traditional meat?

Cultivated meat matches the juiciness of traditional meat by blending muscle and fat cells within specially crafted scaffolds. These scaffolds, often created from materials like gelatin or alginate, are designed to hold moisture and replicate the familiar texture of animal meat.

By adjusting factors like stiffness and water retention, these scaffolds recreate the delicate fat-water balance found in conventional meat. This careful design ensures that moisture release, tenderness, and mouthfeel closely resemble the experience of eating traditional meat.

What are flavour-switchable scaffolds, and how do they enhance cultivated meat?

Flavour-switchable scaffolds are cutting-edge biomaterials crafted to support cell growth while enhancing the sensory appeal of cultivated meat. These scaffolds are made using a gelatin-based hydrogel infused with temperature-responsive flavour compounds (SFCs). Here's how it works: during the cell-culture phase, the scaffold remains inactive, ensuring it doesn't interfere with tissue development. But once heated to typical cooking temperatures, it releases aromatic compounds that emulate the rich, meaty flavours of traditional meat.

This method ensures the scaffold supports cell growth without compromising on taste. The result? A delicious flavour boost during cooking that mirrors the aromas and taste of conventional meat. These scaffolds are instrumental in enhancing the taste and aroma profile of cultivated meat, making it more appealing to consumers.

For those involved in research and development, materials like specialised hydrogels and SFCs are available through Cellbase, a top B2B marketplace for cultivated meat supplies.

Why might cultivated meat be more tender than traditional meat?

Cultivated meat stands out for its ability to achieve a level of tenderness that’s hard to match with traditional farming. This is largely due to the precise control over factors like cell differentiation and scaffold stiffness during its production. These controls ensure that muscle fibres are evenly aligned and contain minimal connective tissue, resulting in a softer and more tender texture.

By fine-tuning these conditions, cultivated meat consistently offers a texture that traditional methods struggle to replicate.