Producing cultivated meat requires precise control of key parameters like pH, temperature, and oxygen levels. Even small deviations can lead to reduced yields, contamination, or wasted resources. QA sensors play a critical role in maintaining these conditions, improving process reliability, and ensuring compliance with regulatory standards.

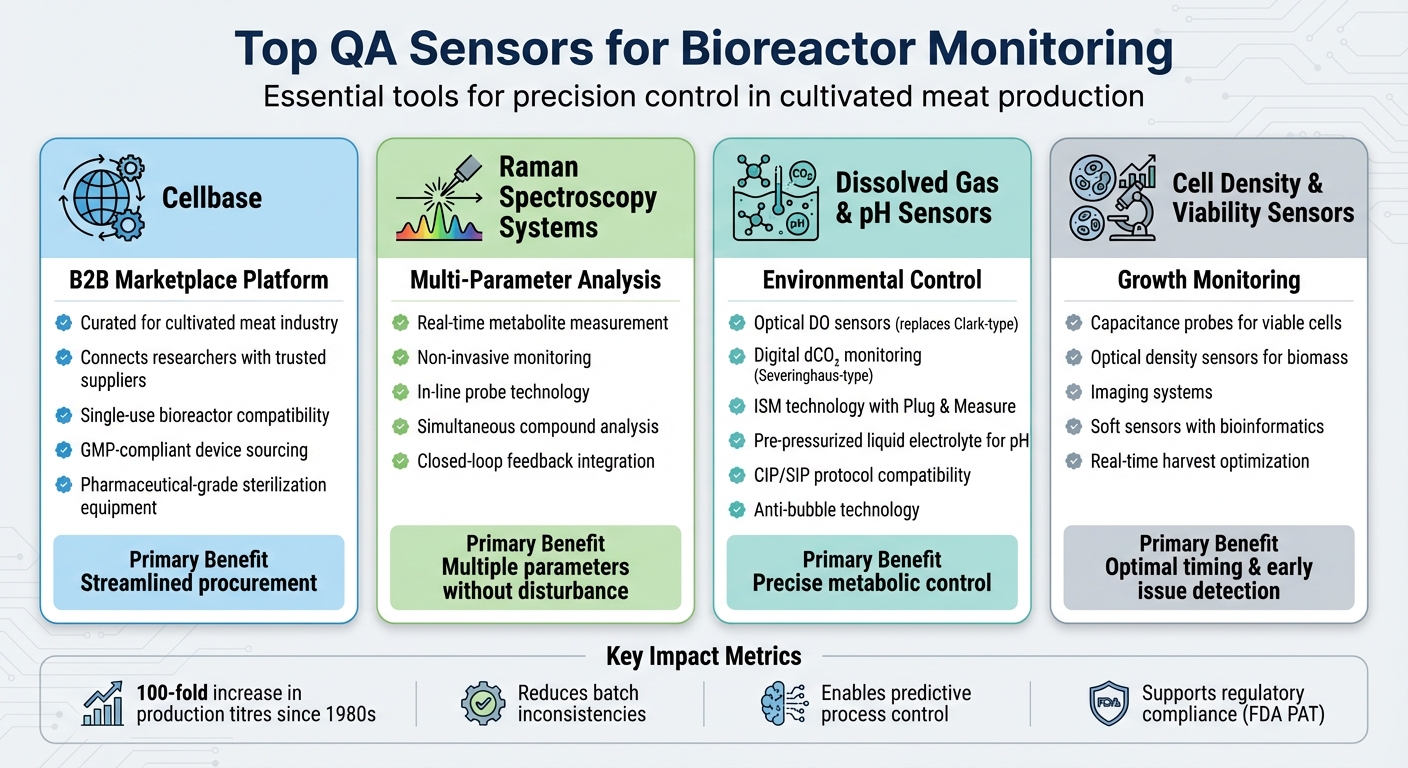

Here’s a quick overview of the top QA sensors for monitoring bioreactors:

- Cellbase: A curated B2B platform for sourcing cultivated meat-specific monitoring tools.

- Raman Spectroscopy Systems: Real-time, non-contact measurement of multiple metabolites simultaneously.

- Dissolved Gas and pH Sensors: Advanced digital sensors for accurate tracking of oxygen, CO₂, and pH.

- Cell Density and Viability Sensors: Tools for monitoring growth and harvest timing, including capacitance probes and optical density sensors.

These sensors ensure consistency, reduce risks, and support scalable production. From single-use bioreactors to digital integration, choosing the right tools today impacts the future of cultivated meat manufacturing.

Comparison of Top QA Sensors for Bioreactor Monitoring in Cultivated Meat Production

Top QA Sensors for Bioreactor Monitoring

Cellbase

Finding the right sensors for cultivated meat production can be tricky. Many general platforms simply don’t cater to the specific needs of this field. That’s where Cellbase steps in - a B2B marketplace designed exclusively for the cultivated meat industry.

Cellbase connects researchers, production managers, and procurement teams with trusted suppliers of bioreactor monitoring tools. Unlike broad lab supply platforms, it offers a carefully curated selection tailored to cultivated meat. Whether you’re searching for sensors compatible with single-use bioreactors, GMP-compliant devices, or equipment that can handle pharmaceutical-grade sterilisation, Cellbase makes the process straightforward. This targeted approach saves time and ensures you find exactly what your production setup requires.

Raman Spectroscopy Systems

Raman spectroscopy is a standout technology for bioreactor monitoring, offering the ability to measure multiple quality parameters simultaneously without disturbing the culture. Using in-line probes, these systems provide real-time insights into key metabolites, making them an excellent addition to other monitoring tools.

"Spectroscopic sensors... are noninvasive and offer interesting options for a simultaneous analysis of various compounds." – Philipp Biechele et al., Engineering in Life Sciences [3]

These systems integrate seamlessly with process control software, enabling a closed-loop feedback mechanism. This means nutrient feeds or environmental conditions can be adjusted automatically in response to changes in metabolic activity [2] [9].

Dissolved Gas and pH Sensors

Precise control over dissolved oxygen (DO), dissolved carbon dioxide (dCO₂), and pH is critical for maintaining cell metabolism and culture health. Modern optical DO sensors have largely replaced older Clark-type electrodes, offering better stability and faster response times, especially in low-oxygen environments [2] [7]. Many now include anti-bubble technology to reduce signal interference [7].

Digital dissolved CO₂ sensors, like Severinghaus-type probes, allow real-time, in situ monitoring of this key parameter. These advanced sensors often feature Intelligent Sensor Management (ISM) technology, which stores calibration data directly in the sensor. This enables "Plug and Measure" functionality and provides predictive diagnostics to track sensor performance and lifespan [4] [7].

"Intelligent Sensor Management, or simply ISM®, is a digital technology for inline process analytical systems that simplifies sensor handling, enhances measurement integrity and reduces sensor lifecycle costs." – Mettler Toledo [4]

For pH monitoring, sensors with pre-pressurised liquid electrolyte reference systems are especially reliable. They offer better reproducibility across multiple sterilisation cycles compared to gel electrolyte sensors, making them ideal for pharmaceutical-grade production environments. These sensors are built to withstand rigorous Clean-in-Place (CIP) and Steam-in-Place (SIP) protocols, ensuring consistent, real-time data collection [10].

Cell Density and Viability Sensors

Rounding out the suite of QA tools, cell density and viability sensors play a crucial role in cultivated meat production. These sensors allow real-time monitoring, helping producers optimise harvest timing and spot potential issues early. Capacitance probes, which detect the dielectric properties of living cells with intact membranes, remain the go-to technology for measuring viable cell density. At the same time, optical density sensors and imaging systems provide complementary data on total biomass [2] [8].

Some advanced systems combine spectroscopic data with bioinformatic tools, often referred to as "soft sensors", to estimate cell viability without invasive sampling [8] [9]. However, reliable on-line viability measurements remain a challenge, and only a few commercial solutions have achieved widespread use [8].

Standardising sensor models across both small-scale R&D units and larger production vessels ensures consistent data during scale-up [4] [7]. Together, these tools deliver the precise, real-time insights needed for quality assurance in cultivated meat production.

Sensor Integration and Data Management

Sensor Placement and Calibration

Proper sensor placement is crucial for gathering accurate data. As bioreactors increase in size, the efficiency of mixing tends to decrease. This can lead to sensors detecting localised "hot spots" instead of providing data that reflects the overall conditions within the vessel [2][6]. To avoid this, sensors should be positioned to sample the bulk medium and placed away from areas with poor circulation.

Another key consideration is sterilisation compatibility. Sensors must be able to endure autoclaving or steam-in-place (SIP) processes without losing their calibration or compromising sterility [4][6][12]. Single-use bioreactors offer a practical solution, as manufacturers can weld sensors directly into the bag or use specialised housings and connectors designed to maintain a sterile environment [4].

"A sensor must endure rather extreme conditions during the sterilisation and stay calibrated." – V. Vojinović et al., Sensors and Actuators B: Chemical [12]

Fouling presents another challenge. Over time, proteins and other biomaterials can accumulate on sensor surfaces, causing baseline drift and reducing measurement accuracy [12]. To counter this, digital sensor technologies now monitor sensor health and lifespan, allowing for timely maintenance [4]. Since bioprocesses can run for weeks, regular validation ensures that sensors remain dependable without requiring constant manual recalibration [6].

Once sensors are correctly placed and calibrated, the focus shifts to capturing and managing continuous data effectively.

Data Collection and Real-Time Monitoring

After addressing sensor placement and calibration, the next step is efficient data collection to support process control. Automated systems now allow for continuous data logging, which is critical for meeting regulatory requirements and enhancing process efficiency [1]. This integration of sensors with real-time monitoring ensures that cultivated meat production meets strict quality standards. By using advanced bioprocess control software, digital sensors provide immediate feedback, enabling closed-loop systems that automatically adjust nutrient feeds or environmental conditions based on live data.

Predictive modelling adds another layer of sophistication. Combining historical and real-time data allows for the maintenance of optimal conditions and early detection of potential issues before they become serious [1]. This is in line with regulatory initiatives like the FDA's Process Analytical Technology (PAT), which focuses on embedding quality into the production process rather than relying solely on end-product testing [3][11]. Tools like neural networks further enhance this capability by interpreting complex spectroscopic data that would be too challenging to analyse manually [6].

sbb-itb-ffee270

Sensors in bioreactors

Conclusion

Choosing the right sensors is a cornerstone for ensuring consistent and scalable cultivated meat production. Real-time, continuous measurements help stabilise processes, making them more efficient and reliable. This directly impacts the production of consistently high-quality products, which is essential for the industry's growth and commercial success [3]. Without dependable sensor technology, inconsistencies between batches can jeopardise both product quality and market viability.

Since the 1980s, bioprocessing methods have achieved a 100-fold increase in production titres [2]. High-precision sensors, designed for durability, play a key role in reducing analytical variability across batches [4]. Meanwhile, automated monitoring systems offer comprehensive data logging, which is crucial for meeting regulatory requirements [1].

Real-time monitoring offers more than just quality control - it drives operational efficiency. By providing live data on metabolic activity and cell density, these systems enable predictive process control, which boosts productivity and reduces resource wastage [5]. Technologies like non-invasive monitoring and sterilisation-ready sensors also minimise contamination risks, protecting entire batches from being compromised [5][4]. For companies transitioning from research to full-scale production, maintaining consistent analytical measurements across all stages ensures optimal adjustments for growth rates, yields, and overall productivity [4].

As highlighted earlier, the industry's shift towards single-use bioreactors and digital sensor management reflects the changing dynamics of cultivated meat production. Moving from the lab to large-scale manufacturing requires foresight; the sensors chosen today will shape the scalability and reliability of tomorrow's operations. Quality isn't just an end goal - it's embedded in every step of the process [3]. By investing in advanced sensor technologies now, companies can set the stage for a future of scalable, high-quality cultivated meat production.

FAQs

What are the advantages of using Raman spectroscopy for monitoring bioreactors in cultivated meat production?

Raman spectroscopy offers a non-invasive, in-line solution for monitoring bioreactors, delivering real-time insights into critical quality attributes without requiring sampling or additional reagents. By directly analysing the culture, this approach eliminates contamination risks and ensures continuous tracking of essential parameters like nutrients (e.g. glucose), metabolites (e.g. lactate), and product concentrations - all within a single process.

This method is especially useful in cultivated meat production, where maintaining precise control over factors like pH levels, dissolved oxygen, nutrient supply, and waste management is crucial for consistent tissue growth. Additionally, Raman systems align with the FDA’s Process Analytical Technology (PAT) framework by reducing batch variability, enabling real-time decision-making, and enhancing automation to minimise the chance of human error.

For those seeking Raman-based monitoring equipment, Cellbase provides a curated marketplace featuring approved analysers and accessories. These tools are designed to integrate seamlessly with standard bioreactor setups, streamlining the procurement process.

How do dissolved gas and pH sensors enhance cultivated meat production?

Dissolved gas sensors, like those tracking oxygen (O₂) and carbon dioxide (CO₂) levels, play a key role in fine-tuning aeration and sparging processes. These sensors deliver real-time insights, helping to create a bioreactor environment that supports efficient cellular metabolism. The result? Improved productivity and steady growth conditions.

In the same way, pH sensors keep an eye on acidity levels within the bioreactor. Maintaining the right pH range is critical for healthy cell growth, and these sensors ensure stability throughout the process. This precision helps produce consistent, high-quality batches of cultivated meat with minimal variation.

Why is it important to position sensors correctly in large-scale bioreactors?

Accurate sensor placement in large-scale bioreactors is essential for monitoring critical parameters like pH, oxygen, and CO₂. These readings provide insight into the varying conditions within the bioreactor, allowing for precise adjustments to maintain a stable and consistent environment.

Getting the placement right doesn't just ensure uniform product quality - it also improves reproducibility and maximises yield. With real-time data from these sensors, maintaining control over the cultivation process becomes much easier, making them indispensable for scaling up cultivated meat production successfully.