Spectroscopy offers a fast, accurate way to monitor growth media in cultivated meat production. By tracking nutrients like glucose and glutamine in real time, it helps optimise cell growth and maintain quality. Two key methods stand out:

- NIR Spectroscopy: Operates in the 780–2,500 nm range, ideal for tracking nutrients and metabolites like glucose and lactate. It's cost-effective and integrates easily with bioreactors but may face interference from water signals.

- Raman Spectroscopy: Uses inelastic light scattering to provide highly specific molecular data. It works well in water-dominated environments, offering precision for metabolites like lactate and glucose but comes with higher costs.

Both methods support automated systems for nutrient delivery and contamination detection, improving efficiency and reducing manual sampling risks. Platforms like Cellbase simplify equipment selection, ensuring compatibility with cultivated meat processes.

NIR Spectroscopy for Growth Media Analysis

How NIR Spectroscopy Works

Near-infrared (NIR) spectroscopy operates within the 780 nm to 2,500 nm wavelength range, focusing on detecting overtones and combination bands of fundamental molecular vibrations [7]. This makes it particularly effective at identifying bonds like C-H, O-H, and N-H, which are commonly found in molecules such as glucose, amino acids, and proteins.

The process involves shining NIR light through the growth media and measuring how much light is absorbed at different wavelengths. Each molecule produces a unique spectral pattern, or "fingerprint", that provides insights into the media's composition. However, because the spectral bands often overlap, advanced chemometric techniques like Partial Least Squares regression are required to extract precise quantitative data [1].

One of the standout benefits of NIR spectroscopy is that it’s non-invasive. Probes can be directly integrated into bioreactors using standard Ingold ports, and they’re built to endure sterilisation cycles (SIP/CIP), ensuring they align with industrial hygiene standards [10]. This ability to measure without disrupting the process makes NIR a valuable tool for monitoring growth media.

NIR Applications in Growth Media Monitoring

NIR spectroscopy is widely used to track critical nutrients and metabolites, such as glucose, glutamine, amino acids, lactate, ammonia, and total cell count (TCC) [6][8]. By providing real-time data, it helps producers detect nutrient depletion early, preventing impacts on cell viability, or identify toxic by-products before they accumulate.

Studies have demonstrated the practical benefits of NIR. For example, one investigation used NIR for on-line monitoring in a stirred-tank bioreactor, achieving prediction errors of 1.54 mM for glucose and 0.83 mM for lactate [8]. For cultivated meat processes, where cells grow on microcarriers, system-specific calibration is crucial due to light-scattering effects caused by the beads. Research at Sanofi Pasteur successfully applied NIR to monitor Vero cells grown on Cytodex 1 microcarriers, achieving prediction accuracies of 0.36 g/l for glucose and 0.29 g/l for lactate [9]. These findings highlight the importance of tailored calibration for different systems.

"NIR spectroscopy (NIRS) is a promising alternative in situ PAT tool... providing a spectrum representative of the 'signature' of all components present in the analysed solution."

- Annie Marc, Process Biochemistry [9]

Another growing use of NIR is in creating "golden batch" profiles - benchmarks that represent optimal process performance. Operators can compare current runs against these profiles in real time. For instance, researchers at Leibniz Universität Hannover used NIR to monitor CHO-K01 cell cultivations in a 7.5-litre bioreactor. Their system detected bacterial contamination in "Batch 3" just 30 hours into the process, as the NIR readings exceeded defined process limits [4].

Basics of NIR spectroscopy – How does NIR spectroscopy work?

Raman Spectroscopy for Growth Media Analysis

While NIR spectroscopy is great for deciphering overlapping absorbance bands, Raman spectroscopy takes a different route. It uses inelastic light scattering to delve into the molecular structure, offering a complementary method of analysis.

How Raman Spectroscopy Works

Raman spectroscopy works by shining a 785 nm laser onto a sample and capturing the photons that scatter inelastically. When these photons interact with molecules, energy shifts occur due to vibrational movements. These shifts create a unique spectral "fingerprint", revealing the molecular structure of components like proteins, lipids, nucleic acids, and sugars [12][5].

The main distinction from NIR spectroscopy lies in what Raman measures. Instead of detecting dipole moment changes, Raman focuses on changes in polarisability of molecular bonds during vibration [5]. This difference makes it especially useful for cultivated meat applications. Why? Because water, which dominates growth media, is almost invisible to Raman's detection. This means Raman can "see through" the water to detect small amounts of nutrients and metabolites, avoiding the interference that often complicates infrared methods [11][12][5].

Raman spectroscopy generates analyte-specific signals that do not overlap with water signals... making it particularly advantageous for applications in cell cultures, where the matrix is predominantly aqueous.

- Morandise Rubini, Researcher, University of Tours [12]

However, because spectral bands can overlap, advanced mathematical models like Partial Least Squares or Principal Component Analysis are often used to extract precise quantitative data from the sharp, specific spectra [12][13][14].

Raman Applications in Growth Media Monitoring

Thanks to its ability to produce detailed molecular fingerprints, Raman spectroscopy has become a powerful tool for in-line monitoring in production environments. Acting as an optical sensor, it tracks nutrient consumption - like glucose and glutamine - and the production of metabolic by-products, such as lactate and ammonia [14]. This real-time feedback allows for automated adjustments, such as optimising nutrient feeding schedules to improve efficiency.

For example, in April 2025, researchers utilised a Viserion Raman spectrometer in five 10-litre CHO cell cultures, achieving highly accurate predictions (e.g., RMSEP of 0.51 g/l for glucose) [12]. Similarly, in March 2018, a team at the Cell and Gene Therapy Catapult in London used an in-line Raman system (Kaiser Optical Systems RamanRxn2™ analyser) to monitor autologous T-cell production. They tracked glucose (R = 0.987) and lactate (R = 0.986) levels with precision, identifying donor-specific metabolic changes and proliferation rates without needing manual sampling [14].

Beyond nutrients and by-products, Raman spectroscopy also monitors cell concentration, evaluates cell viability, and detects potential hazards like Salmonella or E. coli. This ensures consistency across batches and provides a reliable way to characterise media components [11][1][14][15].

NIR vs Raman: Which Method to Use

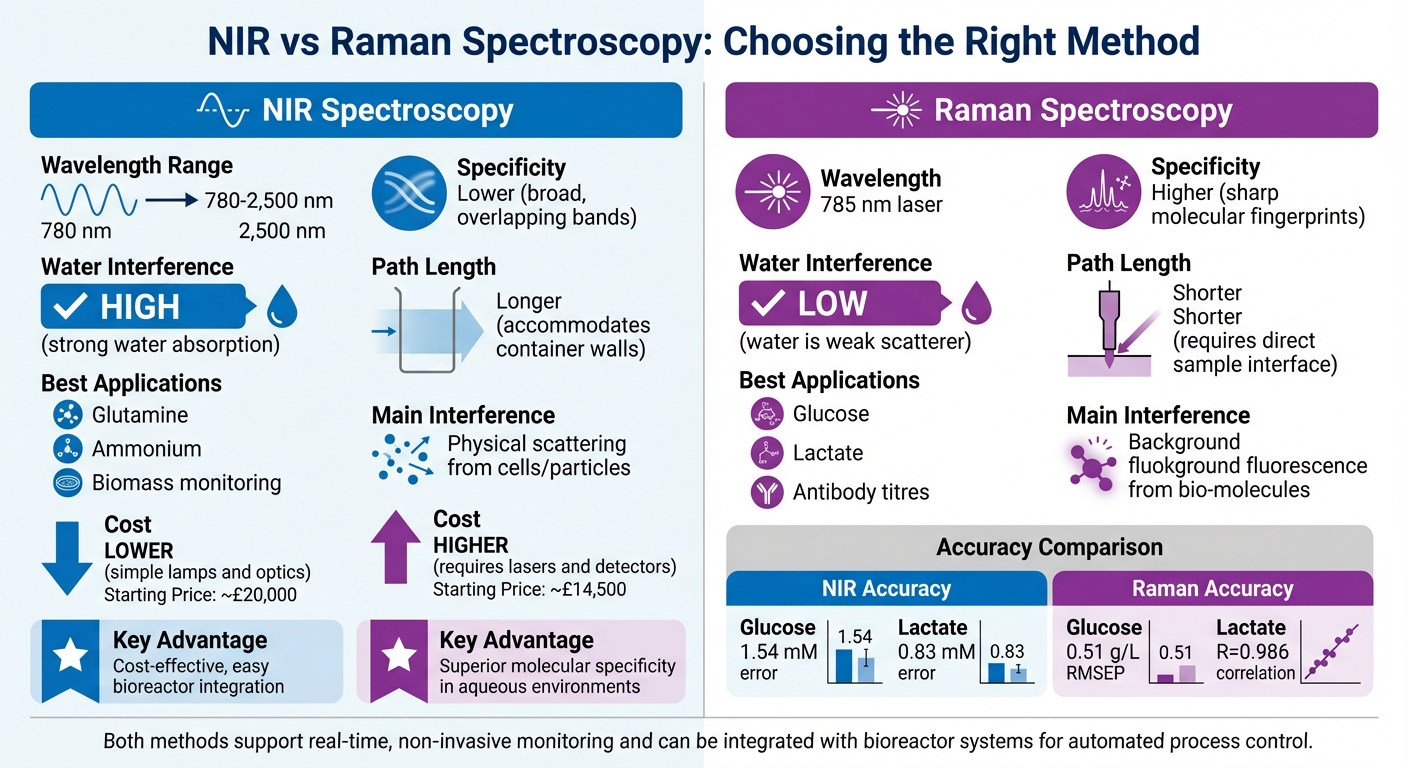

NIR vs Raman Spectroscopy Comparison for Growth Media Analysis

Deciding between NIR and Raman spectroscopy depends on your specific analytes, budget, and the setup of your system.

Comparison Factors

Raman spectroscopy stands out for its ability to deliver highly specific molecular information. It generates sharp, distinct spectral "fingerprints", making it easier to pinpoint individual compounds. On the other hand, NIR spectroscopy produces broad, overlapping bands that demand advanced chemometric tools for analysis [1]. This makes Raman particularly useful for accurately tracking specific metabolites.

Water absorption in NIR can obscure nutrient signals, while Raman's low sensitivity to water ensures clearer detection. However, Raman isn't without its challenges - it can encounter interference from background fluorescence caused by biological compounds like protein hydrolysates [1].

Research involving CHO cell bioreactors has demonstrated that Raman surpasses NIR in predicting glucose, lactate, and antibodies, whereas NIR is more effective for glutamine and ammonium ions [2]. A study conducted in March 2017 by R.C. Rowland-Jones at the University of Leeds further supported Raman's strengths, showing it was more reliable for measuring lactate (RMSECV 1.11 g/L) and glucose (RMSECV 0.92 g/L) in 15 mL miniature bioreactors [16].

From a cost perspective, NIR systems are typically more affordable due to their simpler light sources. Raman systems, however, require advanced lasers and detectors, making them more expensive [1]. The table below highlights these key differences:

| Factor | NIR Spectroscopy | Raman Spectroscopy |

|---|---|---|

| Specificity | Lower; broad, overlapping bands [1] | Higher; sharp molecular "fingerprints" [1] |

| Water Interference | High; strong water absorption [2] | Low; water is a weak scatterer [2] |

| Best For | Glutamine, ammonium, biomass monitoring [2] | Glucose, lactate, antibody titres [2, 19] |

| Cost | Generally lower; simple lamps and optics [1] | Generally higher; requires lasers and detectors [1] |

| Path Length | Longer; accommodates container walls [6] | Shorter; requires a direct sample interface [6] |

| Main Interference | Physical scattering from cells/particles [6] | Background fluorescence from bio-molecules [2] |

Up next, we’ll explore how to apply spectroscopy data for real-time media optimisation in production.

sbb-itb-ffee270

Using Spectroscopy Data in Production

Real-Time Media Optimisation

Spectroscopy transforms raw data into actionable insights, streamlining nutrient delivery in production processes. By enabling simultaneous, non-invasive monitoring of key parameters like glucose, lactate, glutamine, and ammonium, it ensures continuous optimisation of cultures. For instance, when glucose levels dip below the ideal range, the system automatically triggers nutrient feeds. This prevents cell starvation and reduces the risk of toxic by-product accumulation [2].

Creating "Golden Batch" trajectories from optimal production runs allows for early identification of issues, such as contamination or aeration problems [4]. Modern systems take this further - NIR spectroscopy, for example, can estimate nutrient concentrations with a precision within 15% of traditional reference methods. In large-scale bioreactors holding up to 12,500 litres, Principal Component Analysis of NIR data has accounted for 96% of process variability [17].

This constant flow of data integrates seamlessly with bioreactor systems, enabling automated process control to maintain consistency and efficiency.

Connecting Spectroscopy to Bioreactor Systems

The integration of spectroscopy with bioreactor systems takes real-time data to the next level, enabling fully automated feedback control. Immersed probes, capable of withstanding sterilisation cycles and high pressure, relay real-time data directly to the bioreactor control units [6].

A study conducted in September 2018 at the Université de Lorraine compared in situ Raman and NIR probes operating in parallel within a 2-litre CHO cell bioreactor. The results showed that Raman spectroscopy excelled at detecting glucose and lactate, while NIR was more effective for monitoring glutamine and ammonium. Combining the strengths of both methods provides the most comprehensive real-time monitoring for cultivated meat production [2].

Spectroscopy data also feeds into Multivariate Statistical Process Control (MSPC) systems, which continuously compare ongoing batches to established Golden Batch standards. This approach allows operators to detect deviations - whether caused by contamination, nutrient shortages, or equipment failures - within hours instead of days. The result is improved efficiency and greater consistency in production [4].

Sourcing Spectroscopy Equipment via Cellbase

Why Use Cellbase for Spectroscopy Equipment

Choosing the right spectroscopy equipment for cultivated meat production can feel like navigating a maze of technical details. With general-purpose spectrometers offering thousands of configurations [18], it's easy to get overwhelmed without the right expertise.

This is where Cellbase steps in. As a dedicated marketplace for the cultivated meat industry, it connects production teams with trusted suppliers offering NIR and Raman spectroscopy equipment specifically designed for this field. Unlike broader lab supply platforms, Cellbase ensures all listed equipment meets key industry requirements. For example, compatibility with standard 25-mm Ingold ports and the ability to handle Clean-in-Place (CIP) and Sterilise-in-Place (SIP) cycles are guaranteed [3].

Cellbase also provides access to technology that supports in situ monitoring - allowing direct analysis inside bioreactors without the need for manual sampling [6]. This includes fibre-optic probes, flow-through cells, and free-beam spectrometers with larger spot sizes (e.g., 21 mm), which deliver strong, low-noise signals throughout the cultivation process [3]. Transparent pricing further simplifies budgeting, with NIR systems starting at roughly £20,000 and Raman systems at £14,500 [18]. With detailed product descriptions, teams can confidently select equipment that aligns with their production goals.

Key Features of Cellbase for Equipment Procurement

Cellbase takes the guesswork out of sourcing spectroscopy equipment by offering verified listings tailored to the needs of cultivated meat production. Each product listing includes detailed specifications, such as wavelength ranges (typically 780 nm to 2,500 nm for NIR) [5], and compatibility with chemometric software for advanced data analysis. This level of detail eliminates the uncertainty often found with generic supplier platforms that may not fully understand the unique demands of this industry.

Additionally, Cellbase’s expertise helps teams make informed decisions when weighing the benefits of NIR versus Raman technologies. For example, while NIR is often more affordable and delivers higher signal levels, Raman excels in molecular specificity - critical in aqueous environments where water constitutes over 90% w/w of liquid growth media [1]. The platform also facilitates direct communication with suppliers, enabling teams to address specific needs, such as ensuring probes can operate above 2,100 nm while minimising noise with high-quality fibre-optic cables [6]. By focusing on equipment that integrates seamlessly with bioreactor systems, Cellbase helps production teams maintain the conditions necessary for optimal results.

Conclusion

NIR and Raman spectroscopy play a critical role in refining the growth media for cultivated meat. These advanced techniques enable real-time, non-invasive monitoring of key analytes like glucose, lactate, and ammonium. This means production teams can make quick adjustments without interrupting the process - a vital advantage given that media design remains one of the biggest challenges in scaling cultivated meat production [16][19].

Each method brings its own strengths to the table. NIR spectroscopy excels in assessing biomass and overall composition, while Raman spectroscopy provides detailed insights into specific metabolites in aqueous solutions [1]. During miniature bioreactor studies, Raman spectroscopy demonstrated impressive predictive accuracy, making it a reliable choice for precise measurements [16]. Both techniques also support the development of a "golden batch" profile, enabling operators to spot issues like bacterial contamination or aeration problems as soon as they arise [4].

When it comes to selecting the right spectroscopy equipment, the process can be daunting. This is where Cellbase steps in, connecting production teams with vetted suppliers offering tools specifically tailored for cultivated meat applications. Their platform simplifies procurement by offering transparent pricing and detailed product specifications, ensuring the equipment integrates smoothly with bioreactor systems.

Professor Alan G. Ryder highlights the importance of these methods:

Rapid spectroscopic methods if correctly applied can be used for the rapid and effective screening of cell culture media to identify molecular variance and potential issues with media manufacture [1].

FAQs

What are the benefits of using spectroscopy in cultivated meat production?

Spectroscopy techniques like near-infrared (NIR) and Raman bring valuable tools to the cultivated meat industry. They allow real-time, non-invasive monitoring of growth media, making it possible to track nutrients, metabolites, and cell density continuously - without needing to take samples or use extra reagents. This level of monitoring helps maintain tighter process control and speeds up adjustments to media composition, which is essential for ensuring consistent quality when scaling up production.

These methods are also efficient and cost-saving. With a single measurement, they can analyse multiple components at once - such as amino acids, sugars, and lipids - eliminating the need for separate chemical tests. This reduces both labour and material costs while providing data that can improve predictive models, helping to standardise quality and reduce variability between batches.

Another advantage is how easily spectroscopy can integrate with automated systems. For instance, NIR probes can be installed directly in bioreactors to deliver continuous data, enabling automated adjustments to critical parameters like feed rates or temperature. For those in need of specialised equipment, Cellbase offers a range of NIR and Raman instruments designed specifically for cultivated meat production, making it easier to find tools that align with industry requirements.

What are the key differences between NIR and Raman spectroscopy for analysing growth media in cultivated meat production?

Near-Infrared (NIR) spectroscopy is perfect for quick, non-invasive monitoring of the overall composition of growth media. Its ability to provide on-line or in-line control means it can deliver real-time data, helping producers make immediate adjustments during the production process.

On the other hand, Raman spectroscopy offers a precise molecular fingerprint, making it an excellent choice for identifying and measuring specific metabolites such as glucose and lactate. This level of precision is particularly useful for fine-tuning media composition to suit the specific needs of cultivated meat production.

Why is real-time monitoring of growth media important for cultivated meat production?

Real-time monitoring plays a key role in keeping the growth media just right for cultivated meat production. By keeping a close eye on nutrients, metabolites, and cell health, producers can quickly tweak conditions to maintain steady cell growth and enhance the quality of the final product.

This hands-on method cuts out the waiting time associated with traditional offline testing, leading to better yields and less waste. It also ensures resources are used more effectively, streamlining the production process and boosting reliability.