Cold chain packaging is critical for keeping cultivated meat safe and high-quality during distribution. This type of meat is highly sensitive to temperature changes, requiring strict control to prevent spoilage, microbial growth, and contamination. Chilled products must stay between 0–4°C, while frozen ones need –18°C or colder. Without proper packaging and monitoring, products risk becoming unsafe and unsellable.

Key points include:

- Insulation Options: Expanded Polystyrene (EPS) is affordable but less eco-friendly. Polyurethane (PUR) offers better performance for reusable packaging, while Vacuum Insulated Panels (VIPs) are ideal for long-haul shipments due to their superior insulation.

- Temperature Control: Gel packs work for short trips, Phase Change Materials (PCMs) ensure precise control for longer durations, and dry ice is essential for ultra-low temperatures.

- Regulations: UK and EU laws demand strict adherence to hygiene and temperature standards, requiring HACCP plans and monitoring systems.

- Sustainability: Alternatives like biodegradable materials (e.g., feather fibre mats) and reusable containers are reducing waste in cold chain logistics.

For cultivated meat producers, combining the right insulation, temperature control, and monitoring systems ensures safe delivery while meeting compliance requirements and addressing environmental concerns.

What Is a Cold Chain?

Insulation Materials for Cold Chain Packaging

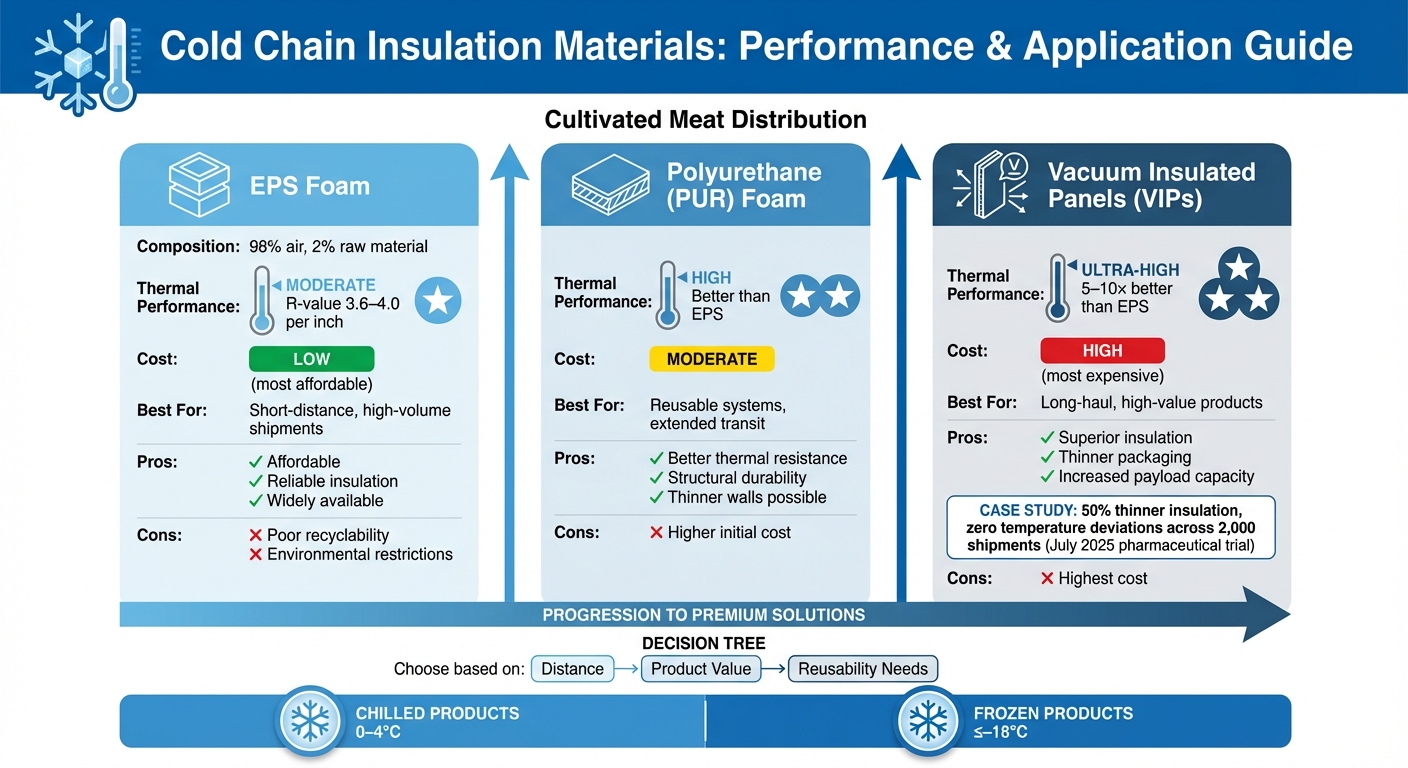

Cold Chain Packaging Materials Comparison for Cultivated Meat Distribution

Selecting the right insulation is crucial for preserving the quality of cultivated meat during transit. The market offers three main options, each with distinct characteristics in terms of thermal performance, cost, and environmental considerations.

Expanded Polystyrene (EPS) foam is the most commonly used insulation material, largely due to its affordability and reliable insulation properties. Made up of 98% air and just 2% raw material[6], EPS has R-values ranging from 3.6 to 4.0 per inch[7]. It’s an ideal choice for short-distance, cost-sensitive shipments. However, its poor recyclability and environmental footprint have led to increasing regulatory restrictions, such as those outlined in the EU Packaging and Packaging Waste Regulation[2].

Polyurethane (PUR) foam offers better thermal resistance and structural durability compared to EPS. Its ability to provide effective temperature control with thinner walls makes it a popular option for reusable shipping systems. While the initial cost is higher, its durability and suitability for multiple uses can offset the expense over time[4].

Vacuum Insulated Panels (VIPs) are the top-tier option for cold chain insulation. By eliminating conduction and convection through a vacuum, VIPs deliver insulation performance that is five to ten times greater than EPS[4]. This efficiency allows for thinner packaging walls, increasing payload capacity - an essential feature for shipping high-value cultivated meat products over long distances. For instance, in July 2025, a global pharmaceutical company tested vacuum-insulated boxes for mRNA vaccine shipments. This trial reduced insulation thickness by 50% and achieved zero temperature deviations across 2,000 shipments[2][7]. Though VIPs are the most expensive choice, they are indispensable for long-haul shipments requiring strict temperature control (0–4°C for chilled or –18°C for frozen goods).

| Material | Thermal Performance | Cost | Best Application |

|---|---|---|---|

| EPS Foam | Moderate (R 3.6–4.0/inch) | Low | Short-distance, high-volume shipments |

| Polyurethane (PUR) | High (better than EPS) | Moderate | Reusable systems, extended transit |

| VIPs | Ultra-high (5–10× EPS) | High | Long-haul, high-value products |

Choosing the right insulation depends on the shipping route and the value of the product. EPS works well for short, cost-sensitive trips, PUR is ideal for reusable systems, and VIPs are necessary for long-distance shipments with strict temperature requirements. The next step is to explore temperature control technologies to finalise your cold chain strategy.

Temperature Control Technologies

Once you've chosen insulation, the next step is selecting a temperature control method. For chilled cultivated meat, maintain temperatures between 0°C and 4°C, while frozen products need to stay at –18°C or colder throughout transit [3]. These methods work alongside insulation to ensure consistent temperature control during shipping.

Phase Change Materials (PCMs) are designed to stabilise temperatures at specific melting points, such as 5°C for chilled and –20°C for frozen products. While their upfront costs are higher, they offer excellent reusability and reduced long-term costs due to their durability. Bio-based PCMs, made from fatty acids or plant oils, further lower both lifetime expenses and environmental impact [4]. For shipments requiring precise temperature control over extended durations (beyond 72 hours), PCMs provide unmatched accuracy, making them ideal for high-value cultivated meat. This precision ensures the product's quality remains intact during distribution.

Gel packs are a budget-friendly option, particularly for domestic shipments lasting 24–48 hours in EPS boxes. When combined with Vacuum Insulated Panels (VIP), they can extend protection to over 72 hours [1]. Gel packs are most effective for standard chilled products (0–4°C) on short- to medium-range routes. For example, in 2025, a poultry processor using EPS coolers with pre-frozen gel packs and LoRaWAN sensors detected a trailer door left open, enabling quick action to prevent spoilage [1]. For best results, place gel packs around the product and eliminate air pockets to avoid uneven cooling or hot spots [1].

Dry ice is crucial for maintaining ultra-low temperatures below –29°C, especially for international or long-haul exports [1]. It provides maximum cooling but sublimates into CO₂, requiring careful handling. Some advanced shipping systems have managed to cut dry ice usage by up to 75% while maintaining temperatures for over 144 hours [4]. This makes it an efficient choice for deep-frozen goods.

Active refrigeration units, like reefer trailers or battery-powered containers, are ideal for large-scale or high-value shipments that require continuous temperature control. Multi-zone trailers are particularly effective, as they allow chilled (0–4°C) and frozen (≤ –18°C) products to be transported in separate compartments within the same vehicle [3]. Battery-powered units can deliver precise temperature control for 72–120 hours per charge [7]. However, these units are designed to maintain temperatures rather than cool products, so it's essential to pre-cool cultivated meat to the target temperature before loading. For instance, a logistics provider using RFID tags with integrated temperature sensors identified a refrigeration issue when the temperature rose to 5°C, exceeding the 4°C limit. The team rerouted the vehicle to the nearest cold storage facility, preventing spoilage and ensuring product safety [3]. These measures are critical for meeting compliance and sustainability goals.

| Technology | Best Use Case | Typical Duration | Cost Level |

|---|---|---|---|

| Gel Packs + EPS | Domestic/Short-haul chilled | 24–48 hours | Low |

| Gel Packs + VIP | Long-distance deliveries | 72+ hours | Moderate |

| PCMs | Premium/High-precision shipments | 72+ hours | High initial / Low lifetime |

| Dry Ice | International/Deep frozen | Extended/Long-haul | Variable |

| Active Units | Large-scale/Continuous control | Indefinite (with power) | High |

Regulatory and Compliance Requirements

The UK Food Standards Agency (FSA) and Food Standards Scotland (FSS) classify cultivated meat as a Product of Animal Origin (POAO) under Annex 1 to Regulation (EC) 853/2004. This classification means that cultivated meat is treated as an animal-origin product, influencing how its cold chain packaging and handling are designed, monitored, and documented [5].

UK Food Standards Agency Guidelines

In the UK, producers are required to include packaging, storage, and distribution processes in their HACCP (Hazard Analysis and Critical Control Point) plans, with explicit temperature requirements [5]. Temperature control is considered a prerequisite for the effective application of HACCP principles. The FSA advises using automated systems for continuous temperature monitoring during transport, with regular calibration of equipment to maintain accuracy [5].

Packaging plays a critical role in preventing pathogen growth. For example, non-proteolytic Clostridium botulinum can produce toxins at temperatures as low as 3°C in vacuum-sealed or modified atmosphere packaging [9]. Products with a shelf life longer than 10 days require additional safeguards. To address these challenges, the FSA and FSS have launched the Cell-Cultivated Products Sandbox Programme (running from February 2025 to February 2027). This £1.6 million initiative aims to create technical guidance on microbiology and production standards for cultivated meat [8].

EU Cold Chain Regulations

EU regulations also impose strict standards on the production and distribution of cultivated meat. Regulation (EC) 852/2004 requires food business operators to establish and maintain permanent HACCP-based procedures to manage risks during production, storage, and distribution [5]. These procedures must include precise temperature thresholds to ensure safety. As the regulation states, "Food business operators shall put in place, implement and maintain a permanent procedure or procedures based on the HACCP principles."

Additionally, packaging and labelling must comply with Regulation (EU) 1169/2011, which governs food information, including durability dates and allergen declarations. Before distribution, cultivated meat products must also be authorised under the Novel Food regulations (Assimilated Regulation (EU) 2015/2283). Traceability across the supply chain is mandatory under Regulation (EC) 178/2002, which also requires protocols for withdrawing or recalling unsafe products [8][10].

HACCP Principles

Adherence to HACCP principles is essential for ensuring the safety of cultivated meat during distribution. The FSA stresses that HACCP-based procedures for hazard control are only effective when paired with good hygiene practices, such as strict temperature control [5]. A robust HACCP plan should include a detailed flow diagram outlining all packaging inputs and waste outputs during distribution, along with clearly documented corrective actions for any temperature breaches during transit.

At least one member of the HACCP team should have completed Level 4 training in HACCP principles to ensure proper implementation and oversight [5].

sbb-itb-ffee270

Sustainable Packaging Solutions

The cultivated meat industry is tackling a major challenge: keeping products at the right temperature while reducing waste. Traditional cold chain packaging creates a lot of waste, much of which isn’t recycled. To address this, the sector is shifting to new packaging methods that balance temperature control with a smaller environmental impact.

Biodegradable Insulation Materials

Non-woven feather fibre mats are emerging as a strong alternative to Expanded Polystyrene (EPS). Made from poultry waste, these mats provide similar thermal insulation as EPS but are fully biodegradable. Christopher Cheeseman from Imperial College London highlights their potential:

"Low-cost, lightweight and sustainable non-woven feather fibre liners have potential to displace the materials currently used for delivering chilled and frozen foods"[13].

However, feather fibre mats can lose their insulating ability if compressed, so designs must include weight support and moisture barriers to maintain effectiveness[13].

Cellulose and pomegranate peel foams are another option. They incorporate Polyethylene Glycol (PEG 400) as a phase change material (PCM), which stabilises temperatures around 2°C - ideal for chilled cultivated meat. These foams have a 25% lower carbon footprint compared to petroleum-based options and naturally inhibit bacterial growth[11]. For applications needing precise temperature ranges between 2°C and 4°C, these materials outperform simpler insulators.

Other innovations include recycled cotton insulation, which decomposes within 18 months when wrapped in biodegradable films[12], and Cruz Cool™ foams, a compostable material made from upcycled food waste and recycled paper pulp[14]. While these options can cost about 25% more than traditional petroleum-based packaging, surveys show that 82% of consumers are willing to pay extra for compostable packaging[14].

| Material | Thermal Performance | Sustainability | Key Limitation |

|---|---|---|---|

| Feather Fibre Mats | Comparable to EPS[13] | High (upcycled waste)[13] | Susceptible to compression and moisture[13] |

| Cellulose/PCM Foam | Stable at ~2°C[11] | High (25% lower CO₂)[11] | Scalability challenges[11] |

| Recycled Cotton | Effective for mailers[12] | High (biodegrades in 18 months)[12] | Needs poly-film wrapping[12] |

| EPS (Traditional) | Consistent performance[13] | Low (80% landfilled in USA)[13] | Expensive recycling (£2,400/tonne)[13] |

Beyond biodegradable options, reusable systems offer another way to cut waste.

Reusable Shipping Containers

Reusable containers use advanced insulation materials like Polyurethane (PUR) rigid foam and Vacuum Insulated Panels (VIP) to maintain temperatures for longer periods than single-use EPS. The reusable cold chain packaging market is expected to grow from US$4.97 billion (around £3.9 billion) in 2025 to US$9.13 billion (around £7.2 billion) by 2034[4].

Companies like Peli BioThermal offer rental programmes for products like the Crēdo™ Cube and Crēdo™ GO. The Crēdo™ Cube, for example, can maintain –20°C for over 144 hours and uses 75% less dry ice compared to traditional methods[4]. These systems meet strict compliance standards while significantly lowering environmental impact.

To make reusable containers work, a closed-loop system is essential. This includes return logistics, professional cleaning, and inspection between uses. UV-C sanitation ensures hygiene, and pre-conditioning containers and PCMs to the required temperature prevents initial thermal lag. Although upfront costs are higher, reusable systems often save money in the long run and reduce waste.

Smart Packaging Sensors

IoT-enabled sensors are transforming how temperature, humidity, and gas levels are monitored during shipping. These sensors help retailers manage inventory better, reducing losses from poor temperature control - a problem that costs around £27.5 billion annually[4].

Smart sensors are also crucial for meeting FSMA 204 (Food Traceability Final Rule) requirements, which demand that firms provide traceability records to the FDA within 24 hours[1]. Advanced sensors, such as real-time RFID trackers, can cut temperature excursions by up to 30% when paired with validated packing procedures[1].

Options range from basic Time-Temperature Indicators (TTIs), which visually show heat exposure, to LoRaWAN sensors that transmit continuous data over long distances. For high-value cultivated meat products, investing in these technologies makes sense, as they protect product quality and reduce the risk of loss. Blockchain integration adds another layer of security, creating tamper-proof records for each product's journey[15].

One challenge is combining electronic sensors with biodegradable packaging without hurting recyclability[15]. For now, companies can focus on using these systems on high-risk routes to gather data before expanding implementation.

Best Practices for Cold Chain Packaging

Ensuring the quality of cultivated meat during transit demands a carefully structured approach. Building on earlier strategies for insulation and temperature control, these practices are key to maintaining product safety throughout the journey.

Pre-condition all packaging components. Before assembly, make sure all components - like insulated containers, gel packs, and trays - are brought to the target temperature. This step avoids thermal lag and reduces the risk of "warm spots" that could promote bacterial growth. Similarly, reefer trailers and containers should be pre-cooled, as they are designed to maintain temperature rather than lower it. This is crucial because bacterial counts in meat can double in as little as 20 minutes when exposed to room temperature (about 20 °C) [16]. Once everything is pre-conditioned, standardising the arrangement ensures consistent temperature across all packages.

Validated pack-out procedures make all the difference. Gel packs should be positioned on multiple sides to eliminate air pockets, ensuring even cooling. For shipments requiring extended temperature control, use barrier layers and pre-freeze gel packs to –20 °C. During transport, leave space around packages to allow airflow, preventing hot spots that could compromise the product. Once a reliable pack-out method is in place, the focus shifts to monitoring.

Real-time monitoring is a must for maintaining control. Place IoT-enabled sensors in the warmest parts of storage areas - not just near cooling units - to gather accurate temperature data. Digital data loggers can automatically keep records, aiding regulatory compliance and ensuring traceability. For multi-stop deliveries, thermal dividers or partitioning curtains help retain cold air when doors are opened. Additionally, following the "2-hour rule" - ensuring meat doesn’t stay above 4 °C for more than two hours during loading or transfer [16] - adds another layer of protection.

| Cold Chain Stage | Temperature Requirement | Action |

|---|---|---|

| Pre-Cooling | 0–4 °C (Chilled) | Rapidly cool products to limit initial bacterial growth [1]. |

| Cold Storage | Chilled: 0–4 °C; Frozen: ≤ –18 °C | Place thermometers between packages to check internal pallet temps [1]. |

| Packaging | Target Temp (Pre-conditioned) | Use validated pack-outs; avoid air pockets; pre-chill containers [1][4]. |

| Transport | Stable Range (Chilled or Frozen) | Pre-cool trailers; manage airflow; use multi-zone compartments [1][3]. |

| Retail Display | 0–4 °C | Quickly transfer from lorry to shelf; monitor for "thermal shock" [1][3]. |

Contingency planning is essential for unexpected disruptions. Even with thorough preparation, equipment failures or delays can occur. Companies should have clear protocols for handling power outages, vehicle breakdowns, or customs delays. Keeping backup gel packs or portable generators on hand is a wise precaution. Regular audits of logistics partners ensure compliance with quality and regulatory standards. For bulk shipments, using reflective or insulated pallet covers and placing cardboard or thermal mats beneath packages can help reduce heat conduction from the lorry floor. Trial runs with thermometers inside insulated boxes are also advisable to confirm that the required temperature range is maintained throughout transit [16].

Conclusion

To optimise cold chain packaging for cultivated meat, it's essential to combine insulation, temperature control, and compliance into a seamless system. Maintaining precise temperature ranges is critical to prevent microbial growth and preserve product quality [1]. Materials such as vacuum insulated panels (VIPs) and phase change materials (PCMs) play a key role in improving insulation performance [2].

Real-time monitoring tools, like IoT sensors and data loggers, are indispensable for ensuring compliance and managing risks proactively. These technologies provide the 24-hour traceability required by frameworks such as FSMA 204 and GDP, enabling quick interventions to prevent spoilage. The stakes are high - temperature mishandling costs the global food industry a staggering US$35 billion annually [1][4].

Sustainability has become a cornerstone of cold chain packaging strategies, driven by regulatory demands and consumer expectations. The industry is moving away from single-use EPS towards reusable systems. This shift is reflected in market projections, with the reusable cold chain packaging sector expected to grow from US$4.97 billion in 2025 to US$9.13 billion by 2034 [2][4].

"The cold chain package stands between safety and spoilage." - Tempk Knowledge Base [4]

Achieving success in cold chain logistics for cultivated meat requires careful planning. Pre-conditioning components to the right temperatures, validating pack-out methods, and selecting materials based on journey duration and environmental conditions are all critical steps. For instance, VIPs are ideal for long-distance shipping, while biodegradable options suit short-haul routes. The ultimate goal remains the same: delivering safe, high-quality cultivated meat while reducing waste and meeting regulatory standards.

For cultivated meat producers seeking tailored solutions, platforms like Cellbase connect companies with trusted suppliers and advanced materials necessary to maintain an efficient and reliable cold chain.

FAQs

How do I choose between EPS, PUR, and VIP insulation for my route?

When deciding between EPS, PUR, and VIP insulation, it's important to align your choice with the length of your route and the temperature demands:

- EPS (Expanded Polystyrene): Ideal for short to medium durations, typically up to 48 hours.

- PUR (Polyurethane): Suitable for medium to long durations, lasting up to 96 hours.

- VIP (Vacuum Insulated Panels): Designed for very long durations, exceeding 96 hours, or for routes with extreme temperature challenges.

Selecting the right insulation ensures your cold chain stays intact and performs as needed.

When should I use gel packs, PCMs, dry ice or active refrigeration?

Gel packs work well for keeping items cool during short trips. Phase change materials (PCMs) are great for maintaining a steady temperature over longer periods. If you need deep freezing for an extended time, dry ice is the way to go. For consistent temperature control during storage or transport of cultivated meat, active refrigeration is the most reliable option. Each method caters to different needs depending on how long and how cold the conditions must be.

What temperature monitoring records do regulators expect during transport?

Regulators mandate keeping accurate temperature monitoring records to verify compliance with specific temperature ranges. For instance, refrigeration should maintain temperatures between 1.7°C and 4°C, freezing must stay below -18°C, and cryopreservation requires temperatures of -80°C or lower. Real-time monitoring systems should also track both temperature and humidity across the entire cold chain to ensure thorough documentation and meet required standards.