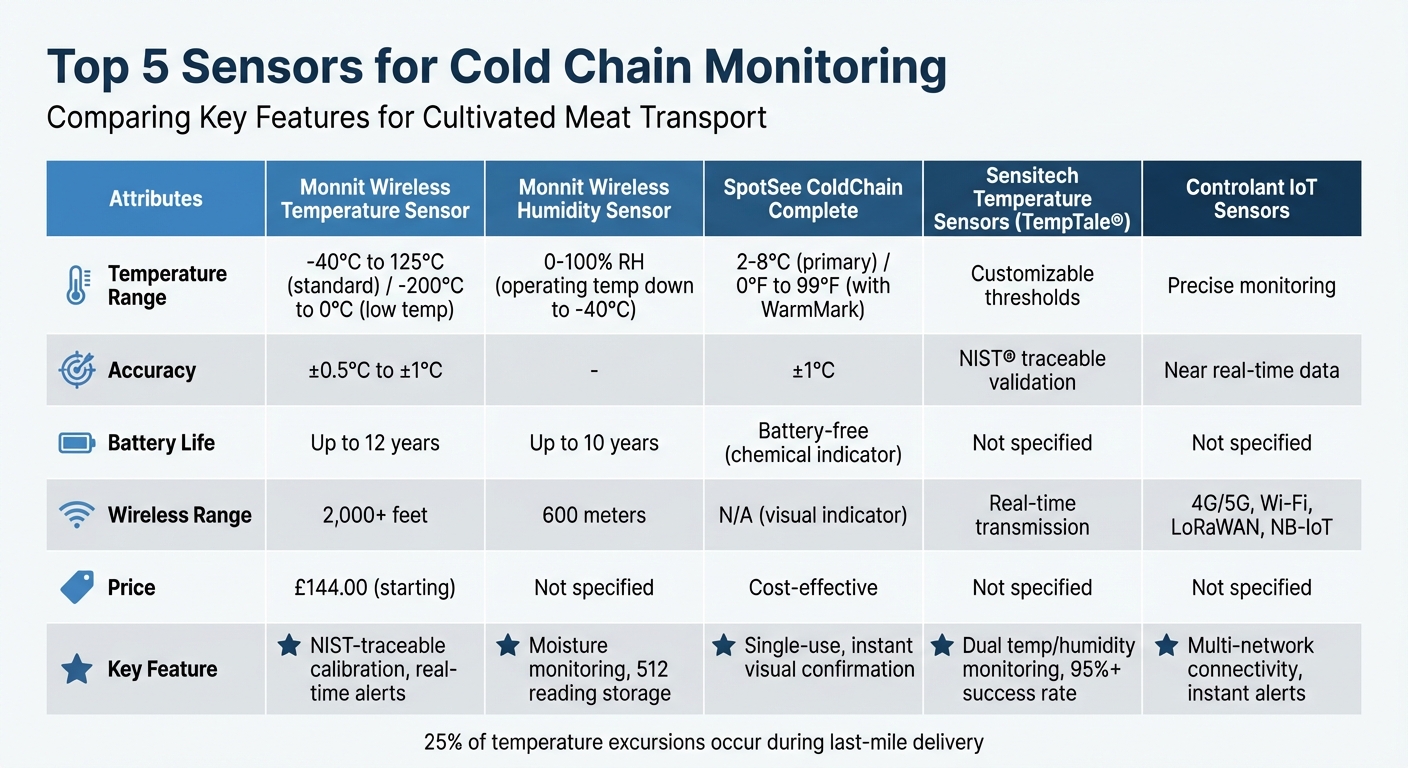

Maintaining precise temperature and humidity during transport is critical for cultivated meat. Small fluctuations can spoil shipments and lead to waste. Advanced IoT sensors now provide real-time monitoring, ensuring product integrity and compliance with strict regulations like FSMA and EN12830. Below are five top sensors designed to safeguard cold chains:

- Monnit Wireless Temperature Sensor: Offers high accuracy (±0.5°C to ±1°C), long battery life (up to 12 years), and instant alerts for temperature breaches. Prices start at £144.00.

- Monnit Wireless Humidity Sensor: Tracks 0–100% RH, with a 600m wireless range and 10-year battery life. Ideal for preventing moisture-related damage.

- SpotSee ColdChain Complete: A single-use visual indicator that changes colour when temperatures exceed limits. Cost-effective and battery-free.

- Sensitech Temperature Sensors: Provide real-time data and alerts via TempTale® devices, ensuring compliance and reducing spoilage risks.

- Controlant IoT Sensors: Use 4G/5G and LoRaWAN for continuous monitoring and instant alerts, ensuring safe conditions during transit.

These sensors help reduce waste, protect quality, and meet regulatory standards. Each offers unique benefits tailored to the challenges of cold chain logistics.

Top 5 Cold Chain Monitoring Sensors Comparison Chart

Monnit's Remote Monitoring Solutions for Cold Chain

1. Monnit Wireless Temperature Sensor

The Monnit ALTA Wireless Temperature Sensor was honoured with the 2024 IoT Product of the Year Award [7]. This sensor is a game-changer for cultivated meat logistics, offering models that cater to a range of temperature needs. The standard version operates between –40°C and 125°C with an accuracy of ±1°C, while the Low Temperature model covers –200°C to 0°C with an even finer accuracy of ±0.5°C [7][8].

Temperature Range and Precision

Built to strict standards, the sensor ensures both accuracy and reliability. Each unit is supplied with NIST-traceable calibration certificates: valid for 25 months for standard models and 13 months for Low Temperature variants [7][9]. These certifications meet Europe's EN12830 cold chain traceability requirements and the FDA's 21 CFR Part 11 electronic record-keeping standards [8]. For added flexibility, standard models can be paired with optional probes ranging from 3 to 100 feet, making them ideal for use in refrigerated lorries or storage units [11].

Battery Life and Power Options

The Monnit sensors are designed with impressive battery longevity. The AA-powered Enterprise models can last up to 12 years [7]. Industrial versions, housed in weatherproof, NEMA-rated enclosures, offer the same durability, even in the harsh conditions of warehouses or transport vehicles [8]. For facilities with existing infrastructure, the PoE•X models provide continuous power through an Ethernet connection [8][11].

Real-Time Monitoring and Alerts

One of the standout features of this sensor is its ability to provide real-time monitoring. It transmits data over distances exceeding 2,000 feet and through more than 18 walls, ensuring reliable performance even in challenging environments. Instant alerts via text, email, or voice are triggered whenever temperature thresholds are breached [7][3]. As Monnit emphasises:

A 2-degree change can ruin a shipment. Instant Monnit real-time alerts help you catch and prevent spoilage [3].

Even if connectivity is temporarily lost, the sensor's on-board storage can hold between 2,000 and 4,000 readings, ensuring no data is missed [10]. Installation is quick and easy, taking just 15 minutes. Pricing starts at approximately £144.00 for the AA-powered model with a 10-foot lead, alongside an annual subscription of £49.00 for up to six sensors [10].

2. Monnit Wireless Humidity Sensor

The Monnit Wireless Humidity Sensor is designed to monitor relative humidity levels (0–100% RH), ensuring the safe transport of cultivated meat shipments [3]. Maintaining proper humidity is crucial, as moisture fluctuations can encourage microbial growth, jeopardising product quality during the final stages of delivery. This sensor operates even in extreme conditions, with a functional range down to –40°C [3].

Humidity Monitoring Capability

This sensor provides accurate humidity readings throughout the cold chain, making it indispensable for sensitive logistics like cultivated meat transport. Its wireless range extends up to 600 metres and can penetrate more than 18 walls, making it suitable for large storage facilities and refrigerated lorries [3]. Such robust performance directly addresses key safety concerns. A study in the MDPI Foods Journal emphasises the importance of monitoring potential hazards during various stages of cultivated meat production, including cell selection, production (e.g., Mycoplasma risks), harvesting, and formulation processes [12]. By maintaining consistent environmental conditions, the sensor helps prevent contamination and preserves the integrity of biological materials during transit. Reliable power management further supports uninterrupted operation.

Battery Life and Power Options

The sensor’s power system is built for long-term use. The Enterprise models, powered by AA batteries, can last up to 10 years [3]. Industrial versions, housed in weatherproof NEMA-rated enclosures, offer up to 7 years of battery life [8][11]. For facilities with Ethernet infrastructure, PoE•X models provide continuous power via Ethernet connections [8][11]. Installation is quick, taking just 15 minutes, and the sensor can store up to 512 readings if connectivity is temporarily lost [8].

Real-Time Monitoring and Alerts

In addition to its range and power features, the sensor offers continuous monitoring and instant notifications. It sends real-time alerts via text, email, or voice message whenever humidity levels breach preset thresholds [3]. This feature is critical, especially when considering that 20% of drugs are spoiled due to cold chain failures [1] - a risk that also applies to high-value cultivated meat products. To ensure ongoing accuracy, the sensors come with NIST-traceable calibration certificates, though these require recertification every 7 months [9][13].

3. SpotSee ColdChain Complete

The SpotSee ColdChain Complete is a single-use visual indicator designed to monitor products that must stay within the 2–8°C range [15]. Instead of relying on electronic sensors, it uses a chemical colour-changing mechanism to provide irreversible evidence of temperature changes. This makes it especially useful for the last-mile delivery of cultivated meat. Its straightforward, battery-free design distinguishes it from electronic alternatives.

Temperature Range and Precision

Maintaining precise temperatures is essential to ensure the quality of cultivated meat during delivery. The SpotSee ColdChain Complete offers an accuracy of ±1°C and, with its WarmMark components, can monitor a range of sensitivities from 0°F (≈ -18°C) to 99°F (≈ 37°C) [14]. It tracks both hot and cold thresholds, with the indicator permanently changing colour if either is breached. This irreversible colour shift provides undeniable proof of any temperature excursion, which is crucial for protecting sensitive components like growth factors and preventing the growth of harmful pathogens such as Mycoplasma [14].

Battery-Free Operation

The ColdChain Complete is powered by a chemical visual indicator, eliminating the need for batteries [15]. This zero-power design ensures consistent performance throughout transit, even during longer delivery periods. It’s a cost-effective solution that meets the 2–8°C temperature requirements [15]. Given that cold chain failures can damage 20%–40% of biopharmaceutical products before they reach consumers, this simplicity and reliability are invaluable [16].

Instant Visual Confirmation

Unlike digital systems, the ColdChain Complete provides immediate visual confirmation upon delivery. A clear colour change allows recipients to quickly verify whether the cultivated meat shipment stayed within safe temperature limits during transit [15]. The indicators are available as either non-adhesive cards or with an adhesive backing for direct packaging application. This allows for a fast and straightforward inspection process, without the need for extra software or connectivity.

sbb-itb-ffee270

4. Sensitech Temperature Sensors

Sensitech specialises in electronic dataloggers designed for precise cold chain monitoring. Their TempTale® series is particularly effective for ensuring the integrity of shipments like cultivated meat, where maintaining product quality is non-negotiable. These devices provide immediate accept-or-reject decision-making at delivery points, a critical feature for safeguarding sensitive goods. Each TempTale® monitor is supplied with a NIST® traceable validation certificate, guaranteeing the accuracy needed for regulatory compliance and quality assurance [17].

Temperature Range and Precision

Sensitech’s monitoring system combines data loggers, wireless sensors, and probe thermometers to continuously record and transmit temperature data to a centralised system. This allows real-time analysis against predefined thresholds, ensuring that cultivated meat stays within safe temperature limits during transport [2].

In 2022, Direct Relief, a non-profit organisation, used TempTale® GEO Ultra devices to deliver insulin-based drugs and cancer medications across difficult terrains during the war in Ukraine. This effort increased their distribution success rate from 84% to over 95% [17].

"We needed a real-time visibility solution to maintain and improve upon the cold chain standards required to ensure a safe and efficacious drug supply." - Brent O'Donnell, Cold Chain Lead, Direct Relief [17]

The system’s precise temperature control is further enhanced by its ability to monitor humidity, ensuring comprehensive cold chain integrity.

Humidity Monitoring Capability

Sensitech’s dataloggers don’t just track temperature - they also monitor humidity. This dual capability is vital for protecting the texture and quality of cultivated meat, especially during last-mile delivery [17][2]. By preventing moisture-related issues, these devices help ensure that products arrive in perfect condition. This is particularly important in the food industry, which accounts for over 50% of all perishable shipments worldwide [2].

Real-Time Monitoring and Alerts

With the SensiWatch® Platform and TempTale® GEO series, Sensitech offers real-time visibility into product location and temperature, no matter where the shipment is [17]. If temperatures deviate from the set parameters, the system immediately sends alerts, enabling logistics teams to act quickly to prevent quality loss [2]. This proactive approach ensures cultivated meat shipments remain in optimal condition, reducing the risk of spoilage during transit.

5. Controlant IoT Sensors

Controlant IoT sensors leverage cellular networks (4G/5G), Wi-Fi, LoRaWAN, and NB-IoT to ensure consistent monitoring of the cold chain for cultivated meat. This advanced connectivity plays a key role in safeguarding product quality, as even small temperature fluctuations can jeopardise the integrity of cultivated meat during transport [4]. Their reliable network compatibility supports accurate and consistent temperature tracking.

Real-Time Monitoring and Alerts

These sensors stand out by offering instant alerts when temperature deviations occur, allowing for immediate corrective actions. Unlike traditional data loggers that simply store data for later analysis, these sensors actively monitor conditions in real time. Their ability to function across multiple networks makes them particularly effective for tracking conditions during last-mile delivery [2][4].

Temperature Control and Accuracy

With a focus on stringent temperature management, these sensors excel at maintaining safe conditions throughout the entire delivery process. Designed for precise monitoring, they ensure that cultivated meat shipments stay within required temperature ranges. Their ability to transmit near real-time data across various network types makes them an excellent choice for the cultivated meat industry. This level of precision is especially crucial for overcoming the unique challenges associated with last-mile delivery, ensuring product safety and quality at every step [4].

Conclusion

Maintaining precise temperature control during last-mile delivery is absolutely crucial for cultivated meat companies. This stage alone is responsible for around 25% of all temperature excursions [20], making it the most fragile link in the cold chain. Even minor temperature shifts - like a rise from 4°C to 7°C - can significantly reduce shelf life, with batch failures reported to reach as high as 19.5% [18][19]. These figures highlight the pressing need for rigorous quality assurance and strict adherence to regulatory standards.

Regulatory compliance also demands meticulous and continuous record-keeping. As outlined in the EU GDP Guidelines, companies must prove that their products haven’t been exposed to conditions that could compromise quality and safety [5]. Modern IoT sensors are indispensable here, offering continuous data logging and creating audit trails that meet HACCP, FSMA, and 21 CFR Part 11 requirements [21]. By automating these processes, companies eliminate the risks of manual errors and ensure they have foolproof records for regulatory inspections.

But compliance isn’t the only benefit. These advanced sensors also safeguard product quality during transit. Solutions like Monnit's wireless sensors and Controlant's multi-network devices provide real-time monitoring and alerts, ensuring cultivated meat stays within safe conditions throughout delivery. Features such as food-grade IP67-rated housing, multi-modal sensing (temperature, light, tilt), and real-time notifications allow for immediate action to prevent spoilage [6]. These tools directly address the vulnerabilities discussed earlier in the cold chain.

For cultivated meat companies looking to enhance their cold chain operations, Cellbase offers a carefully curated Sensors & Monitoring collection. This platform connects buyers with verified suppliers, provides technical integration support, and allows companies to source equipment tailored to their specific needs, ensuring their products remain safe and high-quality from production to delivery.

FAQs

What are the advantages of using IoT sensors for monitoring cold chains in cultivated meat shipments?

IoT sensors play a key role in keeping cultivated meat shipments safe by monitoring critical factors like temperature and humidity in real time. This constant oversight ensures that products stay within the required conditions, preserving cell viability and maintaining safety throughout transport.

Here’s why they matter:

- Instant alerts for quick responses: These sensors immediately flag any deviations, allowing teams to act fast and prevent spoilage.

- Cutting down waste and costs: By catching temperature shifts early, they help avoid product losses and reduce reliance on manual checks, saving both time and money.

- Meeting food safety regulations: Continuous data tracking ensures compliance with food safety standards and provides detailed records for audits.

For cultivated meat producers, Cellbase simplifies the process of sourcing the right IoT sensors. Their marketplace connects you with verified suppliers, making it easy to equip your supply chain with the right tools for every shipment.

How do Monnit sensors help meet regulatory requirements for cold chain monitoring?

Monnit sensors come NIST-certified and include calibrated data loggers that automatically capture time-stamped readings for temperature and humidity. They’re built to align with CDC guidelines, the FDA Food Modernisation Act, HACCP protocols, and 21 CFR Part 11 standards for electronic records and signatures. This ensures your cold chain operations adhere to critical regulatory requirements.

With precise and dependable environmental monitoring, Monnit sensors not only help you stay compliant but also streamline documentation for audits and inspections.

Why is real-time monitoring essential for transporting cultivated meat?

Real-time monitoring plays a crucial role in the last-mile delivery of cultivated meat, ensuring that temperature and humidity levels stay within safe boundaries. This careful control is key to maintaining the product's quality, safety, and adherence to stringent regulatory requirements.

With instant alerts for any deviations, swift corrective measures can be taken to minimise spoilage risks. This ensures the product's integrity is preserved throughout the cold chain, safeguarding its temperature-sensitive nature.