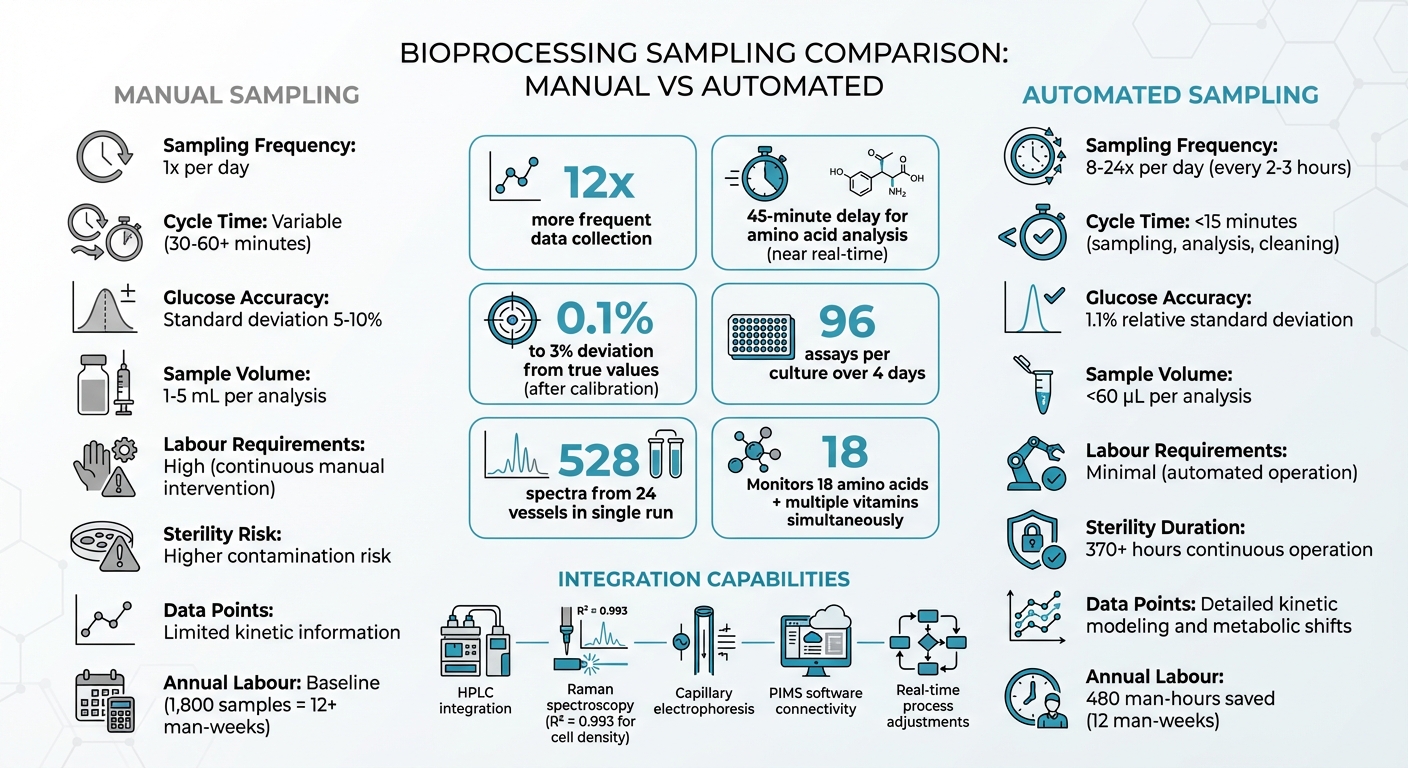

Automated sampling systems are transforming how bioprocesses are monitored, especially in cultivated meat production. These systems offer frequent, precise, and real-time data on critical factors like nutrient levels, metabolites, and cell health - something manual sampling cannot match. By running every 2–3 hours, compared to once a day manually, they provide a clearer picture of metabolic shifts, helping prevent costly production errors.

Key points include:

- Efficiency: Sampling, analysing, and cleaning cycles take under 15 minutes.

- Sterility: Systems maintain sterility for over 370 hours, reducing contamination risks.

- Accuracy: Glucose measurements deviate by just 1.1%, with amino acid analysis offering near real-time insights.

- Labour Savings: Minimises manual intervention, freeing up staff for other tasks.

- Applications: Improves consistency and scalability in cultivated meat production.

These systems integrate seamlessly with advanced tools like HPLC and Raman spectroscopy, enabling precise nutrient monitoring and real-time process adjustments. As a result, they support better quality control, reduced variability, and more efficient production workflows.

Manual vs Automated Sampling Systems: Performance Comparison in Bioprocessing

Research on Automated Sampling Technologies

Research Methods and Approaches

Recent advancements in automated sampling technologies have significantly refined their application in cultivated meat production. These studies focus on integrating automated sampling systems with analytical tools while maintaining sterility throughout the process. Typically, researchers pair automated samplers with established methods like HPLC and capillary electrophoresis to monitor complex metabolites that in-line sensors often struggle to measure accurately.

In May 2020, a team at Vienna University of Technology investigated the Numera system by Securecell AG, utilising Lucullus PIMS software during CHO fed-batch cultivation. They monitored 18 amino acids alongside IgG product levels, maintaining sterility for an impressive 370 hours of continuous operation [2]. Adjustments to system settings, such as the "Push Out Time", became crucial as cell density increased [2].

Similarly, in August 2017, Rosanne M. Guijt from the University of Tasmania employed Sequential Injection Capillary Electrophoresis (SI-CE) to monitor five parallel suspension cultures of Jurkat cells. Over four days, the system performed 96 assays per culture, with each electrophoretic separation taking just 12 minutes. Remarkably, it required only 5.78 mL per flask (less than 60 µL per analysis), making it ideal for high-throughput screening without significantly reducing culture volumes [6]. These precise and systematic methods set the stage for deeper insights into performance data.

Study Results and Performance Data

The findings from these studies underline the efficiency and precision of automated sampling systems. For instance, the Vienna team achieved a 1.1% relative standard deviation for glucose measurements. Furthermore, systematic errors caused by sample dilution were corrected to reduce deviations to as low as 0.1% to 3% from true values [2]. This level of accuracy is far superior to what manual sampling typically offers.

Sampling frequency is another critical advantage. While manual sampling is often limited to once a day, automated systems can sample 8 to 24 times daily, capturing metabolic changes that might otherwise go unnoticed. In the Vienna study, amino acid analysis was completed with a 45-minute delay from sample collection, providing near real-time insights into nutrient depletion [2].

The Tasmania study highlighted another key benefit: by normalising lactate data against real-time cell density measurements, researchers could differentiate the pharmacological effects of compounds like rotenone and clioquinol from simple biomass changes [6]. This level of granularity would be nearly impossible to achieve with traditional manual sampling, where the infrequent data points often obscure critical metabolic patterns.

Sensor Technology for Media Monitoring

Types of Sensors and Analytical Tools

Sensor technology plays a key role in refining real-time media monitoring, especially in cultivated meat production. Various sensors are employed to keep a close eye on media composition and cell health. For instance, standard in-line sensors continuously measure pH, temperature, and dissolved oxygen, ensuring conditions remain ideal for cell growth [7]. When it comes to measuring viable cell density, capacitance probes are the only commercially available on-line solution. These probes use an electric field to detect living cells, as intact cell membranes act as tiny capacitors, distinguishing live cells from dead ones and debris [7].

Spectroscopic sensors offer a non-invasive way to track metabolic activity. For example, UV–vis spectroscopy analyses light absorption and scattering (200–740 nm) to estimate cell density and identify nucleic acids from damaged cells [7]. Fluorescence spectroscopy monitors naturally occurring fluorophores like NADH, NADPH, and tryptophan, providing valuable real-time insights into the culture's metabolic state without interfering with the process [7]. Meanwhile, Raman spectroscopy generates a molecular fingerprint of the media, enabling precise tracking of glucose, lactate, and amino acid levels with minimal error [7][2]. In fact, in-line Raman sensors have shown remarkable accuracy, with a root mean square error of 0.41 mM for tyrosine and 0.24 mM for tryptophan in complex media [2]. These spectroscopic tools complement automated sampling systems by offering fast, non-disruptive metabolic analysis.

Automated systems further enhance precision by linking bioreactors to advanced analysers. This setup allows real-time monitoring of complex nutrients like amino acids and vitamins, which in-line sensors currently struggle to measure accurately [1][2]. For example, UV–vis absorption spectroscopy models have achieved R² values as high as 0.993 for cell density predictions, demonstrating their reliability [7].

Examples of Sensor Integration

Collaborations between technology developers and researchers have led to impressive advancements in sensor integration. One such example is the partnership between Sartorius Stedim Biotech and Tornado Spectral Systems. They incorporated a Raman flow cell prototype into an Ambr 250 High Throughput mini bioreactor system. By pairing it with a BioProfile FLEX2 analyser from Nova Biomedical for automated reference measurements, they created robust models for tracking glucose, lactate, and glutamine in CHO cell cultures. This setup reduced the time gap between spectral and reference data to just five minutes, enabling near-instantaneous data correlation [8].

"Raman spectroscopy is a well-suited PAT tool to nondestructively measure cell culture analytes in-situ... yielding structural information regarding the covalent bonds of the interrogated molecules with high molecular specificity and robustness."

– Marek Hoehse, Sartorius Stedim Biotech [8]

Another example comes from the Vienna University of Technology, where researchers demonstrated how sensor integration can improve precision. Using a 3.6 L bioreactor, they connected it to a Thermo Fisher Ultimate 3000 HPLC and a Roche Cedex Bio HT analyser via the Numera system. This setup allowed real-time monitoring of 18 amino acids and several vitamins, such as niacinamide, folic acid, B12, and riboflavin, during CHO fed-batch cultivation [2]. The automated system produced 528 spectra from 24 vessels in a single run, cutting costs and saving time compared to traditional pilot-scale model building [8].

Process Optimisation and Quality Control

Real-Time Process Adjustments

Automated sampling systems bridge the gap between lab analytics and live production, enabling the use of Process Analytical Technology (PAT) in real time [2]. These systems provide data every two to three hours, creating a comprehensive view of cell metabolism and nutrient use [2]. This high-frequency data captures kinetic values and critical events, such as lactate shifts, that are often overlooked with manual sampling [2][6].

When paired with Process Information Management Systems (PIMS), these analytical results can automatically adjust feeding strategies as needed [2]. Dynamic algorithms identify reaction plateaus, allowing for timely modifications to the process [5]. This capability is especially valuable in cultivated meat production, where maintaining an optimal nutrient balance is crucial for achieving high cell density and yield.

"The higher sampling frequency compared to manual sampling increases the generated information content, which allows easier interpretation of the metabolism... and more accurate detection of process events."

– Paul Kroll, Business Development Manager, Securecell AG [1]

One notable example comes from 2020, when Vienna University of Technology connected a 3.6-litre bioreactor to automated HPLC and Cedex Bio HT analysers via the Numera system. This setup monitored 18 amino acids and multiple vitamins over 370 hours, with deviations as low as 0.1% to 3% [2]. The frequent data collection made it possible to observe reaction kinetics that manual methods would have completely missed.

Benefits and Challenges Comparison

Here’s a breakdown of the main advantages and challenges associated with automated sampling systems:

| Feature | Advantages | Challenges |

|---|---|---|

| Precision & Accuracy | Delivers high precision (1.1% RSD) and eliminates human error in sample preparation [2] | Requires meticulous calibration and adjustments for dilution factors [2] |

| Data Frequency | Allows 8+ samples daily, enabling detailed kinetic modelling [2] | High data volume necessitates advanced software (PIMS) for management [2] |

| Labour & Cost | Cuts down on manual sampling and derivatisation workload [2] | High upfront equipment costs and complex installation [2][5] |

| Sample Volume | Consumes minimal media (<60 µL per analysis), preserving reactor volume for longer runs [6] | Small volumes in tubing can be prone to residue build-up and surface-ratio effects [2] |

| Process Control | Facilitates real-time feeding and nutrient adjustments [2][3] | Demands seamless integration between samplers, analysers, and bioreactor controllers [2] |

Automated systems not only maintain sterility for over 370 hours but also require less than 60 microlitres of media per analysis [2][6]. However, operators must address potential systematic errors in liquid handling, though automated calibration can reduce deviations to as low as 0.1% [2]. Additionally, the "Push Out Time" (POT) in filtration modules may need to be adjusted based on viable cell density to ensure consistent sample delivery as the process evolves [2].

These strategies highlight how automated systems shift cultivated meat production from reactive monitoring to a more proactive, controlled process, complementing earlier advancements in sensor technology and research.

sbb-itb-ffee270

Cellbase Resources for Automated Sampling Systems

Verified Supplier Listings

Cellbase serves as a hub for professionals in the cultivated meat industry, connecting them with suppliers of modular automated sampling systems designed for bioprocess monitoring. Among the offerings is Securecell's Numera, a system that transfers samples directly to third-party analysers for further processing [4]. These systems work seamlessly with software like Lucullus PIMS, which consolidates data from probes, scales, pumps, and analysers, enabling real-time process control [2].

The platform also highlights specialised aseptic sampling tools, such as bbi-biotech's bioPROBE. This tool boasts "sterility by design", employing a patented gas-cushion transport mechanism to prevent biofilm formation and clogging [9]. Additionally, Cellbase features systems compatible with a variety of bioreactor setups, including Eppendorf's BioFlo and DASGIP systems [10]. For instance, the Eppendorf Bioprocess Autosampler can store up to 648 samples at controlled temperatures ranging from 4°C to 40°C [10]. By curating these advanced systems, Cellbase simplifies the search for integrated, high-performance solutions tailored to cultivated meat production.

Simplified Equipment Procurement

Beyond showcasing verified listings, Cellbase makes the procurement process for automated sampling systems straightforward and efficient. The platform identifies systems that can be retrofitted to existing small-scale or bench-scale bioreactor control setups, allowing production teams to enhance their monitoring systems without needing a complete overhaul [10]. These modular systems are capable of completing automated analytical cycles in under 15 minutes [4].

For R&D teams, verified listings offer solutions that automate both sampling and event-based adjustments. This is especially useful for managing small sample volumes - as little as 0.5 ml - helping to minimise media loss [9][10]. The time-saving potential is significant: automated sampling can reduce labour demands by approximately 480 man-hours (equivalent to 12 man-weeks) annually when processing 1,800 samples, compared to manual methods [9]. By streamlining equipment acquisition and enhancing precision, Cellbase supports real-time optimisation for cultivated meat production processes.

Conclusion

Summary and Future Outlook

Automated sampling systems are reshaping how cultivated meat bioprocesses are monitored. By directly linking bioreactors with analytical tools, they provide high-quality data up to 12 times more often - every 2–3 hours compared to the traditional once-a-day approach [1][2]. This frequent data collection allows for a deeper understanding of cell metabolism, faster identification of nutrient depletion, and the calculation of kinetic parameters critical for optimising feeding strategies.

These systems also maintain sterility for longer periods and deliver highly precise measurements, making them a game-changer in bioprocessing. With these advantages firmly established, the stage is set for even greater advancements.

The future of cultivated meat production is heading towards smart biomanufacturing. This involves integrating automated sampling with predictive models and closed-loop process controls. Such advancements will shift the focus from analysing data after the fact to real-time process optimisation. This means feeding strategies can be adjusted on the fly, reducing production time, ensuring consistent product quality, and accelerating time-to-market through continuous monitoring of critical quality attributes [2][3]. For producers, these systems are rapidly becoming a cornerstone for competitive and scalable operations.

Platforms like Cellbase play a key role in this evolution, offering seamless access to cutting-edge automated systems and helping producers stay ahead in the cultivated meat industry.

(English) Numera PAT: automated sampling in bioprocessing

FAQs

How do automated sampling systems enhance consistency in cultivated meat production?

Automated sampling systems play a key role in ensuring consistency in cultivated meat production by removing the unpredictability tied to manual sampling. These systems are designed to collect precise sample volumes at scheduled intervals, which reduces human error and ensures uniformity. This steady and accurate sampling provides real-time insights into nutrients, metabolites, and cell health, enabling better control over the production process and enhancing product quality.

By automating tasks like sampling, preparation, and transfer, the chances of contamination are significantly reduced. Plus, data collection can continue even outside standard working hours, offering a more comprehensive view of the production process. This continuous monitoring allows for quick adjustments to parameters such as feed, temperature, or other critical factors, resulting in consistent batch quality and more dependable production outcomes. For those working in the cultivated meat sector, Cellbase serves as a reliable marketplace for sourcing verified automated sampling systems and analytics tools to help achieve these results.

How do sensors contribute to real-time monitoring in cultivated meat production?

Sensors are essential for real-time monitoring, as they continuously track key process parameters (CPPs) like dissolved oxygen, pH, temperature, cell density, and cell viability. By providing instant feedback, these sensors help operators spot deviations quickly, make timely adjustments, and avoid issues that could compromise product quality.

Modern technologies, such as near-infrared (NIR) and Raman probes, take this a step further by monitoring nutrients like glucose and by-products like lactate in real time, cutting down on the need for manual sampling. Advanced optical tools, like in-situ microscopy, even offer detailed single-cell data on morphology and viability. These innovations are central to Process Analytical Technology (PAT), enabling automation and ensuring consistent control in cultivated meat production.

Platforms such as Cellbase make it easier to source specialised sensors and analytical tools, supporting R&D teams and production managers in setting up effective real-time monitoring systems tailored to their unique workflows.

How do automated sampling systems help reduce labour in bioprocessing?

Automated sampling systems take the heavy lifting out of bioprocessing by handling routine tasks like drawing, preparing, and delivering samples to analytical instruments. Operating on pre-set schedules, these systems eliminate the need for technicians to manually interact with bioreactors and samples. The result? Less repetitive work, fewer chances for human error, and more time for skilled staff to dive into tasks like data analysis and refining processes.

What’s more, these systems allow for much more frequent sampling - sometimes almost continuous - compared to manual methods. This means a wealth of data is generated, enabling real-time monitoring and tighter control over key parameters. With built-in data-management tools, workflows become even smoother by automatically organising sample metadata, cutting down on paperwork and manual data entry.

For those in the cultivated meat industry, Cellbase offers a reliable marketplace to access advanced automated samplers, bioreactor accessories, and analytical tools. This simplifies procurement and supports efficient, high-throughput production processes.