Serum-free media (SFM) is critical for cultivated meat production, replacing animal-derived serum like FBS to address ethical concerns and regulatory demands. However, its high cost - often over 50% of production expenses - is a major barrier to commercial viability. Here's what you need to know:

- Key Cost Drivers: Growth factors like FGF-2 and TGF-β dominate SFM costs, contributing up to 98% in some formulations. Recombinant proteins like albumin are also significant.

-

Cost-Saving Strategies:

- Use food-grade materials, which are up to 82% cheaper than pharmaceutical-grade inputs.

- Employ media recycling technologies to reduce waste and improve efficiency.

- Develop cost-efficient growth factor production methods, such as molecular farming or genetic engineering of cell lines.

- Scaling Impact: Larger bioreactors (e.g., 260,000 L airlift reactors) can cut costs by over 50%. Pilot-scale innovations have reduced SFM costs to as low as £0.06 per litre.

- Challenges: High contamination risks, limited supply of recombinant proteins, and the need for stable, low-cost growth factors.

Reducing SFM costs is essential to producing cultivated meat at competitive prices. Current advancements, such as continuous manufacturing and food-grade substitutions, are bringing the industry closer to this goal.

Dr. Peter Stogios: Low-cost growth factors for serum-free media

Cost Breakdown of Serum-Free Media

Serum-Free Media Cost Breakdown: Growth Factors vs Basal Components

Main Cost Components

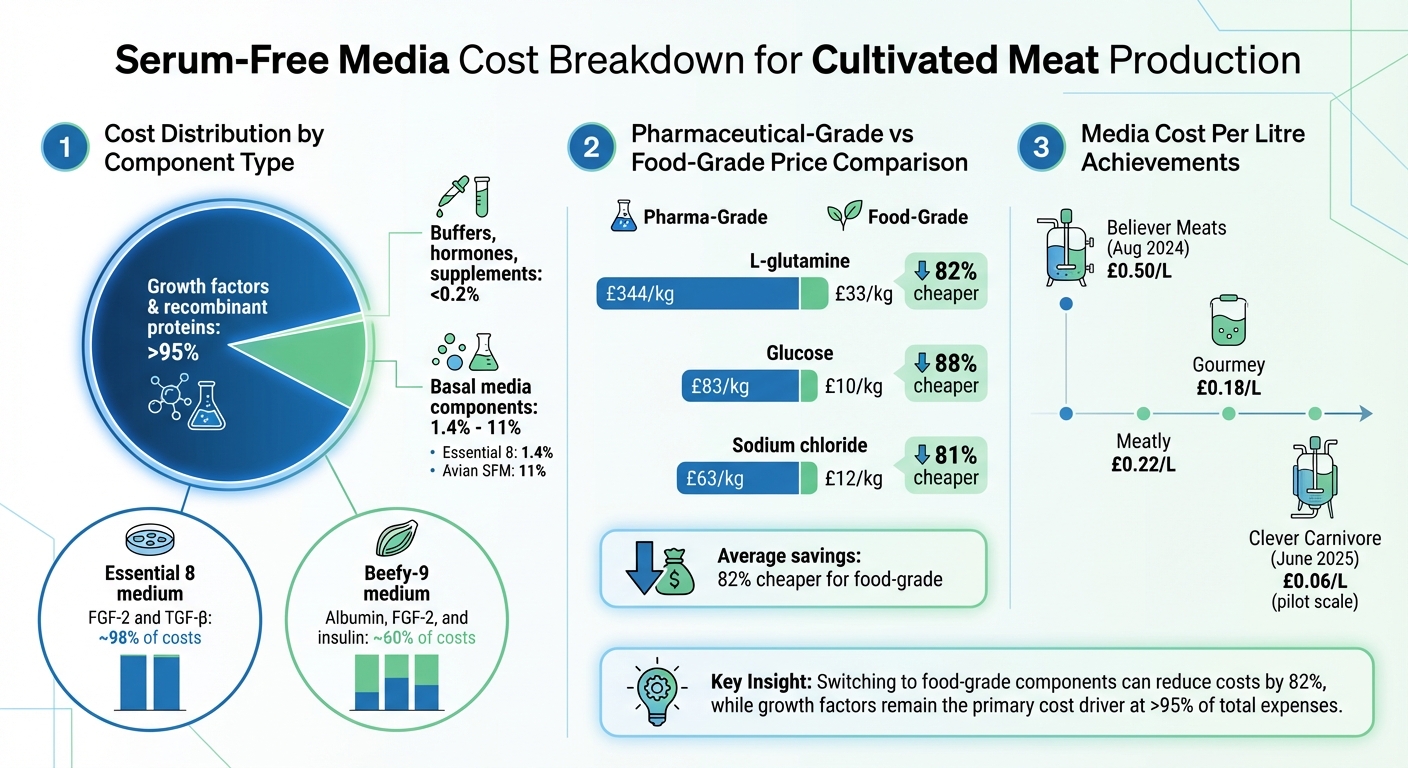

When it comes to serum-free media, growth factors and recombinant proteins dominate the cost structure, often making up more than 95% of the total expense. For instance, in Essential 8 medium, two specific growth factors are responsible for nearly all the costs. In Beefy-9 medium, albumin, FGF-2, and insulin together account for around 60% of the total cost [2].

On the other hand, basal media components - such as amino acids, glucose, vitamins, and salts - contribute only a small fraction. In Essential 8, basal media makes up just 1.4% of the costs, whereas in Avian SFM, it rises to 11% [2]. Buffers, hormones, and other supplements add even less, amounting to less than 0.2% [2].

These differences in cost distribution highlight the potential for significant savings by considering alternative ingredient grades, like food-grade options.

Pharmaceutical-Grade vs Food-Grade Inputs

The cost difference between pharmaceutical-grade and food-grade ingredients is striking. On average, food-grade components are 82% cheaper than their pharmaceutical-grade counterparts when purchased at a 1 kg scale [2]. Some pharmaceutical-grade ingredients can be as much as 90% more expensive. For example, L-glutamine costs £344/kg in pharmaceutical grade versus £33/kg for food-grade. Similarly, glucose costs £83/kg compared to £10/kg, and sodium chloride is £63/kg versus £12/kg [2].

Companies have already demonstrated the potential of food-grade materials. Mosa Meat, in collaboration with Nutreco, successfully replaced 99.2% of their basal cell feed (by weight) with food-grade components, achieving cell growth comparable to pharmaceutical-grade media [2]. IntegriCulture took a different approach by simplifying their medium from 31 components to 16, substituting certain amino acids with food-grade yeast extract to create their "I-MEM2.0" formulation [2].

These substitutions significantly impact the cost of media, bringing down the per-litre price of serum-free formulations.

Media Costs Per Kilogram of Cultivated Meat

The cost of media per litre plays a critical role in determining the overall price of cultivated meat. In August 2024, Believer Meats showcased a serum-free medium costing just £0.50 per litre [1][2]. By June 2025, Clever Carnivore in Chicago reduced costs even further, achieving £0.06 per litre at pilot scale through in-house production of growth factors [6]. Other companies have reported competitive prices, including £0.18 per litre (Gourmey) and £0.22 per litre (Meatly) [6].

These advancements in cost reduction directly affect the price per kilogram of cultivated meat. For example, using a 260,000 L airlift reactor, the production cost for cultivated beef is estimated at £10.20 per kg. In contrast, smaller 42,000 L stirred tank bioreactors result in a higher cost of £23.90 per kg [7]. Believer Meats predicts that their £0.50 per litre medium could enable cultivated chicken to be produced at £4.90 per lb (£10.80 per kg), aligning it with the price of organic chicken [1][2].

Economic Models for Serum-Free Media Production

Modelling Approaches

Techno-economic analysis (TEA) is a key method for assessing the commercial potential of serum-free media production. This approach blends process engineering with cost estimation, borrowing techniques from large-scale bioprocessing industries to evaluate both capital and operational expenses [4][5].

A major focus of these models is the comparison between fed-batch and perfusion systems to determine which is more cost-efficient. Perfusion technology, particularly tangential flow filtration (TFF), has gained attention due to its ability to sustain higher cell densities and enable continuous harvesting over a 20-day period [1][5]. Sensitivity analysis is frequently used to pinpoint the main cost drivers - such as bioreactor scale, cell density, and growth factor prices - that most influence the final cost of production [1][4]. These insights are crucial for validating theoretical models with real-world data.

Another emerging strategy, demand consistency forecasting, examines how the costs of amino acids and protein growth factors might shift when production scales from pharmaceutical to industrial food levels [5]. Some models now integrate lab data from high-density cultures to refine these forecasts, making cost predictions more precise [1]. These advancements in modelling lay the groundwork for empirical validation.

Results from Major Studies

Empirical research is now putting these theoretical models to the test. In August 2024, researchers from The Hebrew University of Jerusalem and Believer Meats showcased continuous cultivated chicken production using tangential flow filtration. Operating with a 300 L pilot-scale system, they developed a model for a 50,000 L facility, achieving cell densities of 130 million cells/ml. This setup resulted in a media cost of £0.51 per litre and a projected final product cost of £5.02 per pound (£11.07 per kilogram) [1].

"Continuous manufacturing can offer cost reductions for scaling up cultivated meat production." - Yaakov Nahmias, The Hebrew University of Jerusalem [1]

Other studies have estimated production costs for wet cell mass at £29.97 per kilogram for fed-batch systems and £41.31 per kilogram for perfusion systems [5]. Achieving a competitive price point for large-scale consumption typically requires reducing costs to around £20.25 per kilogram of wet cell mass [5]. Although perfusion systems offer operational benefits, their higher costs are linked to the expenses of smaller bioreactors and perfusion-specific consumables [5].

How Scale Affects Costs

Scaling up production is one of the most effective ways to bring costs down. Increasing bioreactor volumes from 42,000 L to 210,000 L can lower the cost of goods sold by approximately 31.5%. Additionally, transitioning to 260,000 L airlift reactors can slash costs by more than 50% compared to smaller setups [7].

Larger-scale operations also benefit from in-house production of raw materials like salts, vitamins, and amino acids, which further reduces expenses [6]. For example, in June 2025, Chicago-based startup Clever Carnivore reported achieving a media cost of just £0.06 per litre at pilot scale. They accomplished this by optimising raw material sourcing and in-house preparation, while keeping facility buildout costs under £3.64 million [6].

"Scale-up feasibility may hinge on cost-saving areas such as use of plant-based media components, food-grade aseptic conditions and broad supply chain optimisation." - Corbin M. Goodwin, North Carolina State University [4]

A consistent finding across models is the importance of shifting from pharmaceutical-grade to food-grade standards. Many components used in biopharma are unnecessary for cultivated meat production, and replacing them with food-grade alternatives can significantly cut both capital and operational costs [6][4].

sbb-itb-ffee270

Strategies to Reduce Serum-Free Media Costs

This section focuses on actionable ways to cut serum-free media expenses, a critical step in making cultivated meat production scalable and cost-effective.

Reducing Growth Factor Requirements

Growth factors and recombinant proteins are a major expense, accounting for at least 50% of variable operating costs in cultivated meat production [2]. In some formulations, such as Essential 8, two growth factors - FGF2 and TGF-β - make up nearly 98% of the media cost [2]. Lowering these costs is essential for commercial success.

One promising method involves genetically engineering cell lines to produce their own growth factors. For example, researchers at Tufts University in 2023 developed bovine satellite cells capable of producing FGF2. These cells achieved similar proliferation rates in FGF2-free media as those supplemented with external FGF2 [2]. While this approach eliminates the need for expensive supplements, it raises questions about regulatory hurdles and consumer acceptance.

Another option is using platforms like BioBetter, which leverage tobacco plants to produce growth factors. This method has significantly reduced the cost of growth factors in Essential 8 media, cutting their contribution from 86% to as little as 2% [2]. BioBetter reported in 2024 that their molecular farming platform could lower production costs to just £0.81 per gramme of protein [2].

To meet the target price of £8.10 per kilogramme for cultivated meat, growth factors must be produced at approximately £81,000 per kilogramme, while albumin costs need to drop to £8.10 per kilogramme [8]. Since albumin is expected to make up 96.6% of the total recombinant protein volume required, replacing it with plant-based alternatives like chickpeas or rapeseed is a key focus for cost reduction [8][2].

Another strategy to explore involves adjusting the quality of media inputs.

Using Food-Grade Components

Switching from pharmaceutical-grade to food-grade components can slash costs by over 77% [9]. Food-grade materials are, on average, 82% cheaper than reagent-grade alternatives when purchased at a 1-kilogramme scale [9]. This shift also impacts facility requirements. Pharmaceutical-grade production demands costly clean rooms (Class 8 or higher), whereas food-grade specifications allow for simpler, less expensive facility designs. This adjustment reduces capital costs from £9.12 per kilogramme to about £1.22 per kilogramme, with repayment terms extended to 30 years instead of 4 years [10].

"A key difference in the CE Delft study is that everything was assumed to be food-grade." – Elliot Swartz, GFI Lead Scientist [10]

Plant-derived hydrolysates from sources like soy, wheat, rice, or yeast offer affordable carbon and nitrogen supplies. These hydrolysates may also replace expensive growth factors thanks to their bioactive peptide content [9]. Substituting recombinant human serum albumin with food-grade stabilisers like methyl cellulose can reduce medium costs by up to 73%, making some cell lines 370 times cheaper to grow [11].

While food-grade inputs present risks such as batch variability and contamination (e.g., heavy metals), using GRAS (Generally Recognised as Safe) organisms ensures safety and cost-effectiveness [9].

Beyond input substitution, operational efficiencies can further reduce costs.

Media Recycling Methods

Producing cultivated meat at competitive prices requires 8–13 litres of media per kilogramme of product [8]. Recycling technologies are essential to meet these volume demands while keeping costs low [8]. However, challenges like waste buildup - ammonia from glutamine and lactate from glucose - and the short half-life of growth factors such as FGF2 at 37°C complicate the process [2].

In August 2024, a continuous TFF (tangential flow filtration) process achieved 43% weight per volume. This system supported high-density chicken fibroblast cultures for over 20 days, reducing the projected cost of cultivated chicken to £5.02 per pound (£11.07 per kilogramme). The media used in this study was animal-component-free and cost just £0.51 per litre [1].

"Continuous manufacturing can offer cost reductions for scaling up cultivated meat production." – Yaakov Nahmias, Professor and Founder, Believer Meats [1]

Other approaches include metabolic engineering to replace glutamine with non-ammoniagenic compounds like α-ketoglutarate or pyruvate and substituting glucose with maltose to minimise inhibitory waste [2]. Additionally, engineering thermostable growth factors or using slow-release encapsulation systems can reduce the need for frequent media replenishment [2][8]. Careful management of TFF circulation rates - below 2,500 s⁻¹ - is essential to avoid shear damage to cells while ensuring effective filtration [1].

Implications for Large-Scale Production and Procurement

Can Serum-Free Media Work at Scale?

For serum-free media to become commercially viable, production costs need to drop below £0.63 per litre, with usage levels between 8–13 litres per kilogramme. This would enable a target price of approximately £8.10 per kilogramme [8][1]. In August 2024, Believer Meats demonstrated a promising approach at a theoretical 50,000-litre facility. Using tangential flow filtration, they achieved 130 million cells/ml with an animal-component-free medium costing about £0.51 per litre. This reduced the cost of cultivated chicken to around £4.13 per pound (roughly £9.10 per kilogramme), edging closer to the price of organic chicken [1].

However, contamination risks remain a significant challenge. As David Humbird highlights [10], bacterial contamination can outpace the growth of animal cells, making stringent closed systems and robust sterility protocols essential.

Sourcing Components and Equipment

Scaling production requires a robust procurement strategy. A major hurdle is the limited supply of key components. For instance, capturing just 1% of the global meat market would demand millions of kilograms of recombinant albumin - far beyond current production capacities. To address this, procurement must focus on sourcing bulk alternatives, such as plant-based proteins derived from rapeseed or chickpeas, which could help alleviate these volume constraints [8].

Switching to food-grade inputs instead of reagent-grade materials offers significant cost savings [2]. Additionally, specialised equipment plays a crucial role. Bioreactors with perfusion capabilities, tangential flow filtration systems, and high-density culture sensors are essential for efficient scaling. Platforms like Cellbase connect production teams with verified suppliers offering bioreactors, growth media components, scaffolds, and analytical tools tailored to the industry's needs. These procurement challenges directly influence the research priorities outlined below.

Research Priorities Going Forward

Addressing procurement and scaling challenges requires focused research in three key areas.

First, improving the stability of growth factors is critical. For example, FGF2 degrades quickly at 37°C, requiring frequent media replenishment [2]. Developing thermostable variants or slow-release encapsulation methods could significantly cut costs.

Second, advancing media recycling technologies is essential for cost-effective production. Continuous manufacturing methods, like tangential flow filtration, show potential. However, managing waste accumulation - such as ammonia from glutamine and lactate from glucose - remains a persistent issue [1][2].

Finally, scaling recombinant protein production is vital. Molecular farming and precision fermentation offer promising solutions. BioBetter's tobacco-based platform, for instance, has shown that plant-based systems can bring growth factor costs down to as low as £0.66 per gramme [2]. However, achieving target costs - £81,000 per kilogramme for growth factors and £8.10 per kilogramme for albumin - will require significant infrastructure expansion. The Good Food Institute underscores this point:

Achieving cost-competitive cultivated meat will require growth factors and recombinant proteins to be produced at significantly larger scales and lower costs than their current production formats and scales in the biopharmaceutical sector [8].

Conclusion

Main Findings

Serum-free media stands out as the biggest cost factor in cultivated meat production, making up over half of the variable operating expenses. This highlights the crucial need to focus on cost reduction to make cultivated meat commercially viable. Switching to food-grade alternatives can significantly lower basal media costs, though high-priced growth factors like FGF-2 and TGF-β remain a major expense.

The way forward involves combining multiple approaches. Continuous manufacturing with perfusion technology has shown encouraging potential. Innovative methods, such as BioBetter's molecular farming approach (aiming for growth factor costs as low as £0.66 per gramme) and replacing recombinant albumin with food-grade stabilisers like methylcellulose, could dramatically cut costs [2] [3].

However, challenges persist. For instance, one study found that producing enough recombinant albumin to replace just 1% of global meat consumption would require millions of kilogrammes - far beyond current industrial capacity [3]. This underscores the importance of not only scientific advancements but also robust procurement strategies to address supply constraints. To move forward, the industry must embrace cost-reducing innovations and invest in scalable infrastructure.

Next Steps

The next step is putting these strategies into action, focusing on both research and procurement. Companies should transition from batch processing systems to continuous perfusion methods and incorporate food-grade materials while maintaining strict quality standards. Investing in advanced bioreactors with perfusion capabilities, tangential flow filtration systems, and high-density culture sensors will be critical for scaling production.

On the procurement side, securing bulk supplies from trusted providers like Cellbase is essential to meet the demands of large-scale manufacturing. Aligning procurement efforts with continuous process improvements will be key to ensuring cost-efficiency and reliability. As the industry moves closer to commercial-scale production, having dependable and affordable access to specialised materials and equipment will be just as important as the scientific breakthroughs driving the field forward.

FAQs

What steps can make serum-free media production more cost-effective for cultivated meat?

Serum-free media (SFM) is a major expense in producing cultivated meat, often making up nearly half of the variable costs. Reducing this expense is essential to making cultivated meat as affordable as traditional meat. Here are some effective strategies to cut costs:

- Cutting supplement expenses: Replace costly animal-derived proteins like albumins with plant-based or recombinant alternatives. Additionally, lower the concentration of expensive growth factors without compromising cell growth.

- Choosing economical raw materials: Use affordable ingredients like plant-protein hydrolysates, sugars, and salts instead of costly pharmaceutical-grade reagents when formulating the basal medium.

- Recycling media: Adopt media-recycling or continuous-perfusion systems to recover and reuse up to 80% of spent media, reducing the demand for fresh supplies.

- Streamlining formulations: Employ experimental design techniques to create simpler formulations with fewer components that still maintain efficient cell growth.

By applying these methods, studies have shown it’s possible to bring the cost of serum-free media down to around £0.50 per litre.

Another critical factor is ensuring reliable access to specialised ingredients and equipment. This is where Cellbase plays a key role. As a trusted B2B marketplace, Cellbase connects cultivated meat companies with verified, food-grade raw materials and bioreactor hardware. Centralising procurement through Cellbase provides businesses with transparent pricing, bulk discounts, and expert support - making large-scale production a more practical and cost-effective reality in the UK.

What are the key challenges in scaling serum-free media for cultivated meat production?

Scaling serum-free media (SFM) for cultivated meat comes with its fair share of obstacles. One of the biggest challenges is cost. SFM typically makes up more than half of the variable operating expenses in most production models. Growth factors and recombinant proteins, key components of SFM, remain pricey. While some progress has been made by substituting serum components with food-grade alternatives for certain cell lines, a one-size-fits-all solution is still out of reach. On top of that, the intricate formulations of SFM complicate large-scale production and recycling, leading to more waste and higher costs.

Bioprocessing challenges add another layer of complexity. Issues like slow cell growth rates, metabolic inefficiencies, and damage caused by shear forces limit the density of cells that can be achieved in bioreactors. These problems become even more pronounced as media viscosity increases at higher cell concentrations. Although advanced approaches such as continuous manufacturing and specialised filtration methods show potential, they demand expensive and intricate infrastructure, making them less accessible.

Lastly, supply chain reliability remains a critical concern. Securing a steady supply of consistent, high-quality SFM ingredients at the volumes needed for commercial production is no small feat. Platforms like Cellbase aim to address this by offering a marketplace for verified serum-free components, helping cultivated meat companies streamline their scaling efforts.

How does using food-grade components help lower production costs?

Switching to food-grade components can slash costs by replacing pricey pharmaceutical-grade materials like fetal bovine serum and bovine serum albumin with more affordable, widely available food-grade alternatives. These changes tackle one of the biggest expenses in cultivated meat production: the high variable operating costs tied to growth media.

Using food-grade inputs not only cuts costs but also paves the way for scaling up production, bringing cultivated meat closer to being a financially practical option for large-scale manufacturing.