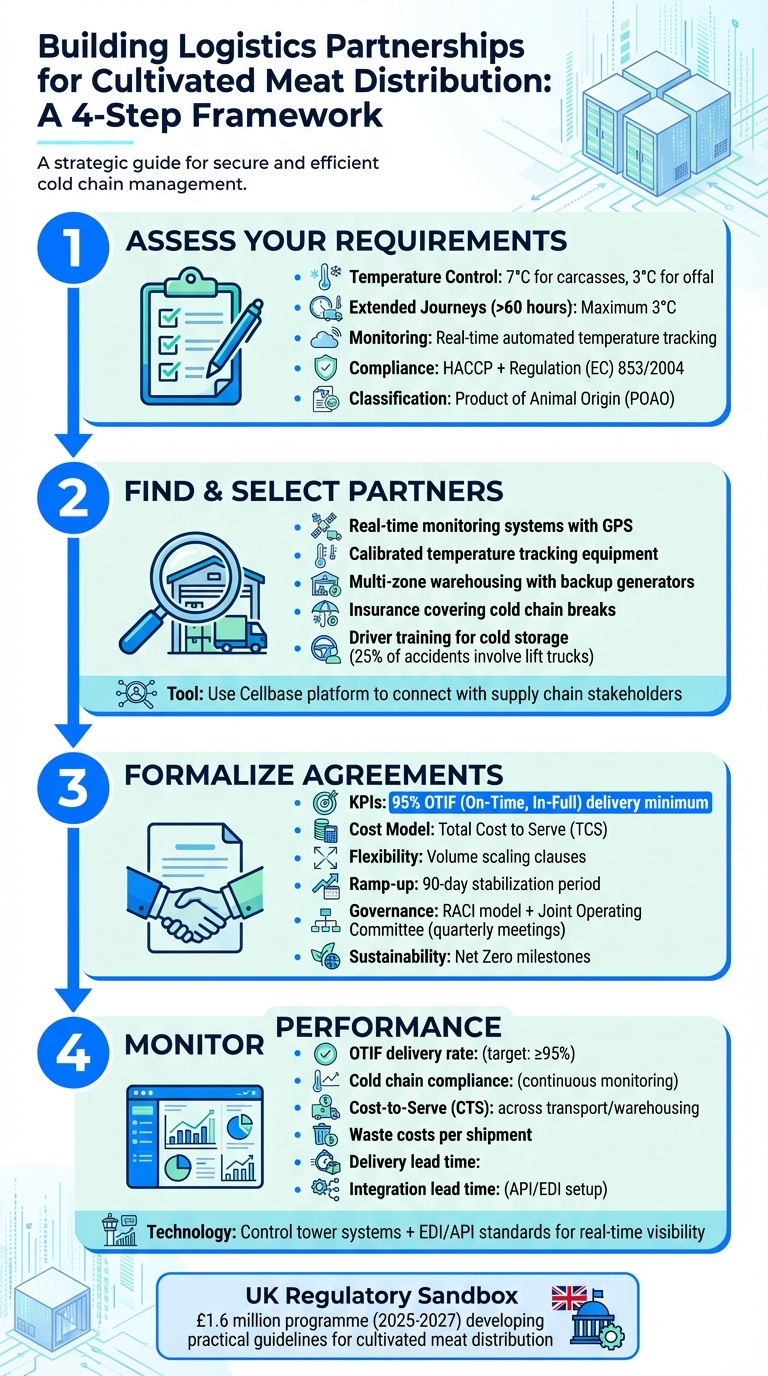

Maintaining a reliable cold chain for cultivated meat is no small task. It requires strict temperature control, real-time monitoring, and compliance with UK food safety regulations. Here's what you need to know:

- Regulations: Cultivated meat is classified as a Product of Animal Origin (POAO) in the UK, requiring adherence to Regulation (EC) 853/2004.

- Temperature Control: Products must be kept at precise temperatures (e.g., 3°C for offal, 7°C for carcasses). Any fluctuation risks contamination.

- HACCP Compliance: Every stage of distribution must follow Hazard Analysis and Critical Control Points for traceability and safety.

- Logistics Providers: Look for partners offering real-time monitoring, calibrated equipment, and insurance for cold chain failures.

- Regulatory Sandbox: A £1.6 million programme (2025-2027) is underway to develop practical guidelines for cultivated meat distribution.

To succeed, companies must define their needs, evaluate logistics partners carefully, and formalise agreements with clear KPIs and risk-sharing terms. Tools like Cellbase can also help connect supply chain stakeholders and streamline operations.

4-Step Framework for Building Cultivated Meat Logistics Partnerships

How RSA Global and Americold Joined Forces to Strengthen the GCC Cold Chain

Assessing Your Logistics Requirements

Before reaching out to logistics partners, it's essential to clearly define your distribution needs for cultivated meat. This groundwork will shape your partnership agreements and ensure you're targeting providers equipped to meet your specific requirements. By clarifying these needs, you'll also be better positioned to evaluate the technical capabilities of potential partners.

Temperature-Controlled Storage and Transport

Maintaining precise temperature control is a Critical Control Point (CCP) in your HACCP plan [2]. Since cultivated meat is classified as a Product of Animal Origin (POAO), it must adhere to minimum temperature standards: 7°C for carcasses and 3°C for offal [6][2]. However, tighter controls may be necessary for certain products like burgers or mince.

Transport vehicles must include automated systems that continuously track and record air temperatures throughout the journey [6]. This isn't just about meeting regulations; it's about preserving product quality. Any disruption in the cold chain risks introducing contaminants, undermining the aseptic conditions maintained during bioreactor production [4]. When selecting a logistics provider, ensure their monitoring equipment is properly calibrated and capable of capturing data at the thickest part of the product [6]. These technical capabilities are non-negotiable when it comes to safeguarding your product.

For extended journeys exceeding 60 hours, regulations impose a maximum air temperature of 3°C [6]. Given the sterile conditions under which cultivated meat is produced, maintaining consistent low temperatures is crucial to prevent pathogen growth [2][6].

Shelf-Life and Regional Distribution Planning

Your product's shelf-life must be clearly outlined in your HACCP plan, as it determines your allowable distribution timeframe [2]. Early-stage cultivated meat products, often in comminuted forms like mince, may have different spoilage profiles compared to whole cuts [4]. Understanding these differences is vital for planning transport durations and storage needs.

The Cold Chain Federation defines the cold chain as "a network of specialist facilities and vehicles that store perishable goods in a secure temperature-controlled environment" [5]. For cultivated meat, this network must minimise delays to maintain freshness. Many in the industry are adopting decentralised production hubs - referred to as the "every village its own factory" model - to simplify long-distance cold-chain logistics [4]. This strategy not only ensures fresher products but also reduces the risks of equipment failures or delays that can lead to significant losses [5].

When designing your distribution plan, assess whether your logistics partner can support rapid dispatch protocols. UK regulations permit "warm meat" transport (prior to reaching the target core temperature) for up to two hours if it is technologically justified [6]. If your production process necessitates this flexibility, confirm that your partner can facilitate departures within three hours of harvesting [6].

Once you’ve outlined these operational requirements, the next step is to identify logistics providers that align with your standards.

Finding and Selecting Logistics Partners

Once you’ve outlined your distribution needs, the next step is finding logistics providers who can meet those requirements. In the cultivated meat industry, this means partnering with companies that have a solid track record in managing perishable goods while adhering to strict regulatory standards. Look for a partner that excels in maintaining precise temperature control and complies fully with food safety laws.

What to Look for in a Logistics Partner

When evaluating logistics partners, focus on their ability to provide real-time monitoring systems. Their vehicles should be equipped with calibrated instruments capable of continuously tracking both surface and core temperatures [6][7]. It’s a good idea to audit their equipment to ensure their thermometers are accurate. Automated data logging combined with GPS monitoring is another must-have, as it enables early detection of any temperature irregularities [6][7]. These features set a high standard for evaluating potential partners.

Insurance is another key consideration. With around 25% of workplace transport accidents involving lift trucks, proper driver training for cold storage is non-negotiable [5]. Beyond safety, confirm that the partner’s insurance policy specifically covers losses caused by "breaks in the cold chain", whether due to equipment failure, delays, or even theft [5]. This level of coverage ensures your products are protected at every stage.

If you’re planning to scale operations, look for partners with multi-zone warehousing. They should offer facilities with multiple temperature zones and backup systems like generators to safeguard products during power outages [7]. For companies transporting meat before it’s fully chilled - under the "warm meat" derogation - ensure the logistics partner can provide the necessary documentation and technological justification required for regulatory approval [6]. These details can separate reliable providers from those who only meet the bare minimum.

Using Cellbase for Supply Chain Integration

Beyond the day-to-day logistics, integrating your supply chain is essential for efficiency. This is where Cellbase comes into play. The platform connects cultivated meat companies with key supply chain stakeholders, ranging from startups to established players in the food and biotech sectors. It’s particularly useful for addressing challenges in areas like "Distribution & Shipping" and "Raw Materials and Supply Chain" [1]. By leveraging Cellbase, you can map out upstream suppliers and infrastructure providers, aligning your logistics partnerships with your broader procurement strategy to build a seamless distribution network.

sbb-itb-ffee270

Structuring and Formalising Partnership Agreements

Once you've identified the right logistics partner, the next crucial step is formalising the partnership. A well-structured agreement not only safeguards both parties but also establishes clear expectations from the outset. This isn't just about ticking legal boxes - it's about building a framework that can grow alongside your cultivated meat operations.

Creating Partnership Proposals

A solid proposal should outline shared goals that benefit both sides. Start by using a Requirements Traceability Matrix (RTM), which links your specific needs - such as cold chain compliance and shelf-life requirements - to your partner's capabilities [8]. This ensures transparency and sets clear success benchmarks.

Focus your proposal on four main areas:

- Transportation: Cover first, mid, and last-mile delivery for cultivated meat.

- Warehousing: Include temperature-controlled facilities to maintain product integrity.

- Value-Added Services: Consider extras like kitting or labelling.

- Technology Integration: Ensure readiness for API or EDI systems.

For example, successful partnerships have previously merged cold storage with distribution networks to achieve faster transit times and lower emissions. Aligning infrastructure with distribution goals can give your operations a real edge.

Also, include scenario-based evaluations. Ask potential partners to provide operational plans for challenges like peak season demand, customs delays, or managing multi-node fulfilment [8]. This will show how they handle pressure, not just how they perform on paper.

With these detailed proposals, you're ready to move into negotiating terms that reflect both performance expectations and risk-sharing.

Negotiating Terms and Conditions

Once the proposals align on shared goals, the next step is hammering out the contractual details. Go beyond just discussing unit rates - use a Total Cost to Serve (TCS) model that factors in variable costs like SLA breaches, dwell times, and returns processing [8]. This approach gives a more realistic picture of the partnership's overall cost.

Contracts should include:

- Clear KPIs and Rewards: Set performance thresholds and include Corrective Action Plans (CAPs) for underperformance [8].

- Volume Flexibility Clauses: These allow for scaling operations without incurring heavy penalties, which is especially important for the growing cultivated meat sector.

- Tiered SLAs: Introduce a 90-day ramp-up period to stabilise performance before strict penalties kick in [8].

Risk-sharing models are also essential. Use a RACI model (Responsible, Accountable, Consulted, Informed) to assign responsibilities for issues like cold chain failures, equipment breakdowns, or delays. Oversee these with a Joint Operating Committee (JOC) that meets quarterly, ensuring alignment between senior leadership teams [5][8].

Lastly, incorporate sustainability goals. For example, set "Road to Net Zero" milestones, like adopting emission-free transport refrigeration units or transitioning to renewable energy in cold storage [5]. These shared commitments can not only differentiate your supply chain but also help reduce long-term costs.

Managing and Monitoring Partnership Performance

Once you've formalised your logistics partnership, the next step is to focus on effective monitoring systems. These systems should not only address potential issues before they escalate but also encourage ongoing improvements. In the cultivated meat industry, maintaining rigorous oversight is particularly important due to strict cold chain requirements and regulatory demands. To achieve this, it’s crucial to establish clear performance metrics that can measure the effectiveness of these systems.

Defining Key Performance Indicators

Start by identifying metrics that prioritise both operational efficiency and product safety. For instance, aim for a minimum of 95% OTIF (On-Time, In-Full) delivery across all stages.

Cold chain compliance is non-negotiable. Continuously monitor temperature-controlled environments to ensure the integrity of your products. Another critical metric is the cost of waste - this includes the financial and environmental impact of disposing of spoiled, expired, or damaged goods. Keeping this cost in check directly affects profitability and compliance with environmental standards [9].

Key performance indicators (KPIs) to monitor include CTS (Cost-to-Serve) across warehousing and transport, as well as waste costs per shipment. Delivery lead time is another significant factor, as delays can lead to additional costs, such as the need for specialised transport or extra facility setups [9]. For long-term planning, measure integration lead time - the time it takes to set up API or EDI systems. This metric offers insight into your partner's digital capabilities and readiness [8].

These KPIs are not just numbers; they’re tools for identifying areas where technology can improve processes.

Using Technology for Process Improvement

Technology can shift partnership management from being reactive to proactive. Centralised dashboards, often referred to as "control tower" systems, provide real-time updates on delivery status, temperature conditions, and issue resolution [8].

Adopting EDI (Electronic Data Interchange) and API (Application Programming Interface) standards ensures smooth data exchange for orders and deliveries. For the cultivated meat supply chain, advanced sensors that monitor temperature, pH, and dissolved oxygen are essential to maintain product quality [3]. According to the Food Standards Agency, automated monitoring systems must operate continuously, with regular checks to confirm their accuracy [2].

Use shared dashboards to track CAPs (Corrective Action Plans) with clearly defined and time-bound milestones. If a partner repeatedly fails to meet agreed standards, it could signal deeper systemic issues, potentially requiring a full HACCP (Hazard Analysis and Critical Control Points) review [2]. To prevent performance issues from escalating, establish a tiered governance structure. This could include monthly operational reviews and quarterly Joint Operating Committee meetings to spot and address performance drifts early on [8].

Additionally, aligning your technology tools with strategic sourcing efforts can improve overall supply chain integration. For example, Cellbase can assist in sourcing specialised cold chain equipment and monitoring tools specifically designed for cultivated meat distribution.

Conclusion

Strong logistics partnerships are the backbone of scaling operations in the cultivated meat sector. As SupplyChain360 puts it, "Market expansion is constrained by logistics; companies now treat logistics partnerships as strategic infrastructure" [8]. This evolution from short-term contracting to long-term collaboration tackles one of the 15 critical challenges the industry must overcome to achieve commercial viability [1].

To build on the operational strategies discussed earlier, taking a structured approach is key. Start by clearly defining your needs, carefully pre-qualify potential partners, and establish measurable KPIs, such as aiming for 95% on-time, in-full (OTIF) delivery rates [8]. Incorporating API and EDI standards can also help ensure real-time visibility across your supply chain.

Maintaining these standards requires ongoing oversight. Use tools like Joint Operating Committees and control towers to monitor performance and ensure partnerships stay aligned with your business goals. With the UK Food Standards Agency and Food Standards Scotland conducting a regulatory sandbox from February 2025 to February 2027 [2], it's more important than ever to form partnerships that can adapt to changing compliance landscapes.

For companies looking to integrate their supply chain strategies, Cellbase provides access to specialised cold chain equipment and monitoring tools tailored for cultivated meat distribution. By combining thoughtful partner selection, diligent performance management, and the right technology, businesses can lay the groundwork for sustainable growth in this rapidly evolving industry.

FAQs

What should I consider when choosing a logistics partner for distributing cultivated meat?

When choosing a logistics partner for distributing cultivated meat, keeping cold chain management at the forefront is crucial. This ensures the product stays in top condition throughout storage and transportation. The partner should also have a solid grasp of food safety regulations and reliable systems for tracking and compliance, which are vital for maintaining consumer confidence.

It's also important to find a partner who can adapt to your needs as your business expands - from small-scale production to larger commercial operations. Look for flexibility and a dedication to sustainability, as these qualities are essential for tackling the environmental challenges tied to logistics in this growing industry.

How can companies comply with UK cold chain regulations for cultivated meat distribution?

To meet UK regulations for cold chain logistics in cultivated meat, businesses need to adhere to guidelines set by the Food Standards Agency (FSA) and other relevant authorities. A critical aspect of compliance is ensuring temperature control during both transportation and storage to avoid contamination and spoilage. For example, cultivated meat must typically be kept below 7°C, though exact requirements can vary depending on the specific product.

Maintaining safety involves several key practices: continuous temperature monitoring, detailed record-keeping, and strict hygiene protocols throughout the supply chain. Staying up to date with regulatory changes and participating in specialised training can also help companies maintain compliance. Following these steps is crucial to safeguard product quality and align with UK standards.

How does technology support the cold chain for cultivated meat distribution?

Keeping cultivated meat at the right temperature is crucial for preserving its safety and quality. From transport to storage, precise temperature control is key to preventing spoilage and ensuring the product stays intact.

To achieve this, advanced tools like insulated packaging, temperature-monitoring systems, and refrigerated vehicles play a vital role. These technologies help stabilise temperatures throughout the supply chain, ensuring the meat arrives in perfect condition. By using these modern solutions, businesses can maintain top standards in distributing cultivated meat.