Producing cultivated meat requires precise bioreactor control. AI-driven systems, paired with advanced sensors, help maintain optimal conditions for mammalian cell cultures by monitoring parameters like pH, dissolved oxygen, glucose, and biomass. Key advancements include:

- The Cultivated B Biosensors: Detect glucose, amino acids, and lactic acid at picomolar levels, eliminating manual sampling.

- Scentian Bio VOC Sensors: Inspired by insect olfactory systems, these sensors detect volatile compounds to assess cell health and detect contamination early.

- Multi-Parameter Sensors: Measure multiple variables (e.g., pH, temperature) simultaneously, enabling real-time process adjustments.

These sensors ensure consistent quality while reducing risks during large-scale production. Platforms like Cellbase simplify sourcing and integration, offering GMP-compliant options and expert support for cultivated meat bioprocessing.

Aber Instruments | Optura | Biomass Sensor

sbb-itb-ffee270

Best Sensors for AI Bioreactor Control

The production of cultivated meat now relies heavily on advanced sensors that provide continuous, high-resolution data. These sensors do more than just monitor - they supply the critical data streams that machine learning algorithms need to fine-tune bioprocessing in real time. By doing so, they create a seamless link between raw data collection and AI-driven process optimisation in cultivated meat production.

The Cultivated B AI-Driven Biosensors

In February 2025, The Cultivated B, based in Burlington, Canada, introduced a cutting-edge line of multi-channel biosensors. These sensors are capable of detecting glucose, amino acids, and lactic acid at concentrations as low as picomolar levels[4]. By delivering a continuous and sterile data feed, they eliminate the need for manual sampling, enabling more accurate predictive modelling.

"Our sensor technology for bioreactors accelerates the learning curve of bioprocessing, ensuring high-quality output and exceptional product quality. I am confident this will empower industries to streamline workflows and enable scalable processes through enhanced automation." - Hamid Noori, Founder and CEO, The Cultivated B[4]

These sensors are particularly effective in optimising media formulation by tracking key metabolites like glutamate and lactate. This is a crucial advancement, as media costs represent a significant expense in cultivated meat production[4].

Scentian Bio Insect-Inspired AI Biosensors

Scentian Bio has taken inspiration from insect olfactory receptors to create sensors that detect volatile organic compounds (VOCs) and metabolic by-products in the bioreactor's headspace. These biosensors are customisable, allowing them to target specific molecules relevant to different cell lines, making them highly adaptable to various cultivated meat processes[8].

The AI-powered system analyses VOC patterns to assess cell health and metabolic states, offering early warnings before traditional indicators like pH or dissolved oxygen reveal issues. This is particularly useful for identifying contamination, as microbial activity often produces distinct volatile signatures. Automated control systems can then respond swiftly, minimising potential disruptions.

Multi-Parameter Bioreactor Sensors

In addition to biosensor advancements, integrated multi-parameter sensors are enhancing process control even further. These platforms measure multiple variables - such as pH, dissolved oxygen, temperature, and biomass - within a single unit. Using non-contact digital optical methods, they provide reliable readings even under the challenging conditions of large-scale bioreactors[6].

For instance, the Hamilton Incyte system uses permittivity measurements to monitor viable cell density and biomass quality in real time. This data directly correlates with the texture and sensory characteristics of cultivated meat products[7].

These systems enable "data fusion", where AI models combine multiple parameters to present a detailed overview of the bioprocess. For example, a slight pH change paired with rising CO₂ levels could signal impending cell stress, prompting immediate adjustments like altered aeration rates. This approach has proven effective, with real-time Raman-based glucose control achieving an 85% improvement in titre for mammalian cell cultures[6].

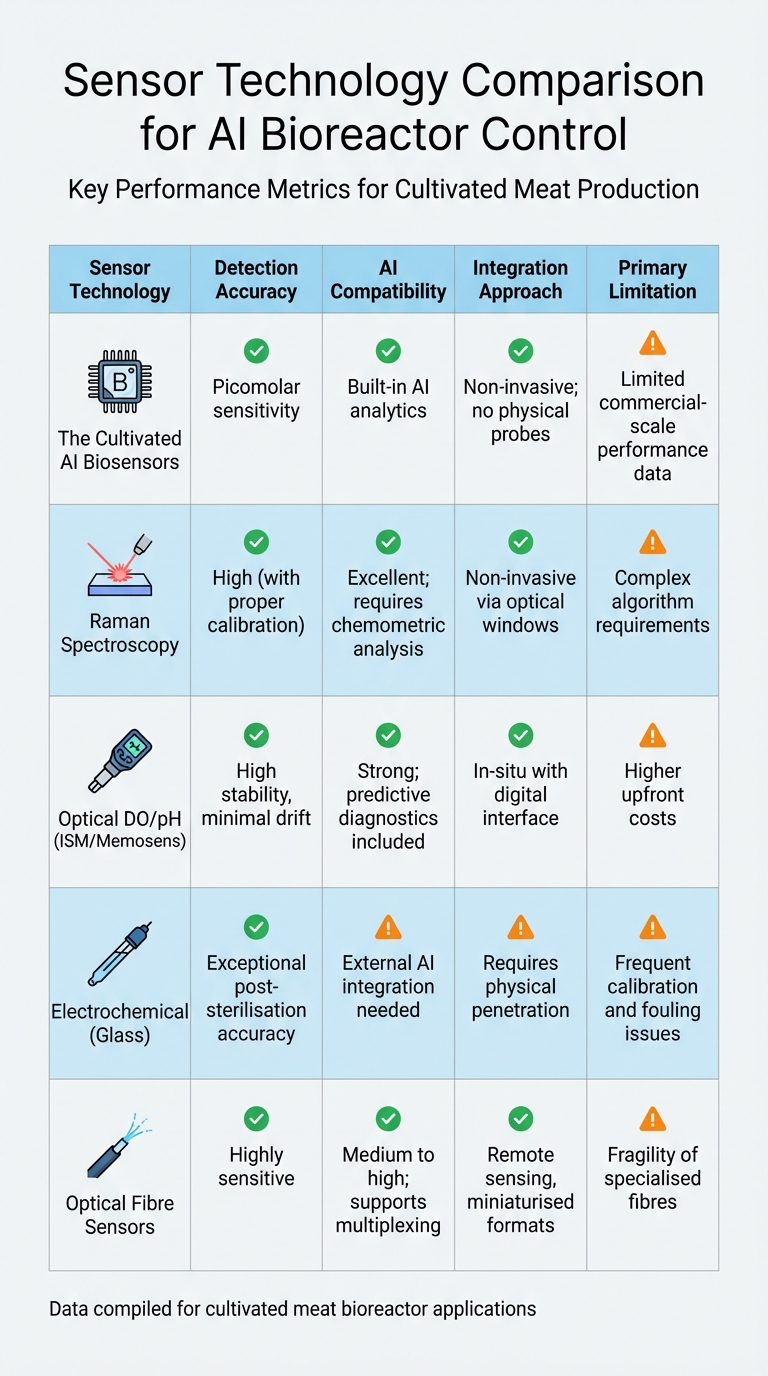

Sensor Technology Comparison

AI Bioreactor Sensor Technology Comparison for Cultivated Meat Production

When it comes to AI-driven bioreactor control for cultivated meat, selecting the right sensor involves striking a balance between detection accuracy, seamless AI integration, and cost considerations. Below, we delve into the specifics of different sensor technologies.

The Cultivated B biosensors are noteworthy for their exceptional sensitivity, detecting glucose, amino acids, and lactic acid at picomolar levels[5][4]. They feature built-in AI analytics that simplify data processing and a non-invasive design that reduces contamination risks. However, their long-term performance in large-scale commercial settings remains largely untested.

Multi-parameter spectroscopic sensors, particularly Raman-based systems, excel in monitoring multiple biochemical parameters simultaneously using a single probe. For example, real-time Raman-based glucose control has achieved an 85% increase in titre for cultivated meat cultures[11]. That said, these sensors require complex chemometric algorithms for calibration and setup, which can pose challenges[3].

Traditional electrochemical sensors are known for their precision - glass pH electrodes, for instance, perform exceptionally well after sterilisation. However, they demand regular maintenance due to issues like signal drift and fouling, which limits their scalability[2]. Optical pH sensors (optodes) address some maintenance concerns but are hindered by issues such as signal drift, a narrow dynamic range, and sensitivity to ionic strength[3].

Sensor Performance Comparison Table

Here’s a breakdown of how these sensor technologies perform across key metrics:

| Sensor Technology | Detection Accuracy | AI Compatibility | Integration Approach | Primary Limitation |

|---|---|---|---|---|

| The Cultivated B AI Biosensors | Picomolar sensitivity[5][4] | Built-in AI analytics[4] | Non-invasive; no physical probes[5] | Limited commercial-scale performance data |

| Raman Spectroscopy | High (with proper calibration)[3] | Excellent; requires chemometric analysis[3] | Non-invasive via optical windows[3] | Complex algorithm requirements |

| Optical DO/pH (ISM/Memosens) | High stability, minimal drift[9] | Strong; predictive diagnostics included[9][10] | In-situ with digital interface | Higher upfront costs |

| Electrochemical (Glass) | Exceptional post-sterilisation accuracy[3] | External AI integration needed | Requires physical penetration[3] | Frequent calibration and fouling issues[2] |

| Optical Fibre Sensors | Highly sensitive[2] | Medium to high; supports multiplexing | Remote sensing, miniaturised formats[2] | Fragility of specialised fibres[2] |

Digital sensor platforms equipped with Intelligent Sensor Management (ISM) capabilities are emerging as a scalable solution. These systems offer predictive diagnostics that assess whether sensors can be reused safely, reducing the risk of mid-run failures that could jeopardise costly batches of cultivated meat[9][1]. Although digital sensors involve a higher initial investment, they significantly cut operating expenses by automating maintenance schedules and reducing manual labour. This level of precision and reliability is critical for meeting the demanding standards of cultivated meat production.

Finding Advanced Sensors on Cellbase

Cellbase makes it easier than ever to find cutting-edge sensors designed specifically for cultivated meat production. Their Sensors & Monitoring collection offers a curated selection of high-performing systems, all vetted to meet strict standards for AI-driven bioreactor control. These sensors focus on automated monitoring, helping to minimise manual work while ensuring accurate data logging for compliance and process optimisation. With Cellbase, integrating advanced sensor technology into precise bioprocess control becomes straightforward and accessible.

To simplify the search, Cellbase includes helpful filters like AI compatibility and GMP compliance tags. The Bioreactor Components collection features high-quality parts from trusted manufacturers. These components are designed to work seamlessly with major bioreactor brands and include advanced data analysis capabilities, making integration with existing AI control software a smooth process.

If you have specific questions about sensors or need guidance on integration, Cellbase has you covered with their "Ask us anything" feature, connecting you with Cell Ag Experts. Additionally, the platform's Insights & News section provides practical resources, such as the guides "Process Analytical Technology for Batch Consistency" and "Analytical Methods for Live-Cell Monitoring" (published 6 January 2026). These guides can help you decide which sensors are best suited for real-time AI adjustments.

Cellbase also takes the hassle out of procurement. They offer transparent pricing, global shipping, and cold chain options to maintain sensor calibration and functionality during transit. For specialised equipment like custom control modules or sensors not yet listed, you can request quotes directly through their supplier onboarding and sourcing forms. With new suppliers added weekly, Cellbase is constantly expanding its range of advanced monitoring solutions for the cultivated meat industry.

Conclusion

Selecting the right sensors is a cornerstone for efficient AI-driven control in bioreactor systems used for cultivated meat production. Advanced sensors deliver continuous, real-time insights into critical parameters like pH, dissolved oxygen, CO₂ levels, and cell density. This data empowers AI algorithms to make precise adjustments, ensuring optimal conditions throughout the process. As METTLER TOLEDO aptly states, "Batch-to-batch consistency is the central aim... and [precision] measurement solutions are designed to enable it" [10].

The adoption of digital sensors equipped with Intelligent Sensor Management (ISM) has brought a new level of reliability. These sensors offer predictive diagnostics, monitoring their own health and lifespan - an invaluable feature for cultivated meat production, where extended batch durations leave no room for unexpected sensor failures [10][12]. Beyond reliability, these systems also facilitate comprehensive data logging, aiding regulatory compliance while ensuring consistent product quality and optimised yields.

Platforms like Cellbase help address the challenge of sourcing suitable sensors. By providing a curated marketplace, Cellbase tags sensors with essential specifications such as AI compatibility and GMP compliance. Additionally, their team of Cell Ag Experts is available to assist with integration, aligning perfectly with the focus on bioreactor monitoring for cultivated meat applications.

Reliable sensor data is the backbone of effective AI control. By prioritising advanced digital sensors with features like anti-bubble technology and predictive diagnostics, cultivated meat producers can ensure consistent texture and flavour across batches while meeting regulatory standards.

FAQs

How do AI-powered sensors optimise bioreactor control for cultivated meat production?

AI-powered sensors are transforming bioreactor control in cultivated meat production by offering precise, real-time tracking of essential parameters such as pH, dissolved oxygen, temperature, and metabolite levels. This real-time data enables automated adjustments, cutting down on manual intervention and reducing the chance of deviations that might affect cell growth or yield.

Technologies like Raman spectroscopy and optical fibre sensors take this a step further by allowing simultaneous, non-invasive measurement of multiple metabolites. This provides detailed insights to maintain optimal culture conditions without disrupting the system. Additionally, digital sensors equipped with Intelligent Sensor Management (ISM) technology bring predictive diagnostics into the mix. This means operators can proactively address issues like sensor calibration or potential failures before they interfere with production.

With these advanced sensors in place, bioreactor processes become more consistent, scalable, and efficient, paving the way for reliable and commercially viable production of cultivated meat.

What advantages do multi-parameter sensors offer for bioreactor systems?

Multi-parameter sensors bring a host of benefits to bioreactor systems, particularly in cultivated meat production. They allow for the simultaneous monitoring of crucial conditions like pH, dissolved oxygen, temperature, and metabolite levels, ensuring precise and efficient oversight. With real-time data collection, teams can make accurate adjustments to maintain the ideal environment, cutting down on manual effort and boosting process consistency.

Another important advantage is their role in ensuring regulatory compliance. These sensors provide detailed data logging and documentation, which are critical for meeting the standards required in commercial-scale operations. By delivering a complete picture of the bioreactor's conditions, they enable rapid identification and correction of any issues, leading to higher yields, less waste, and smoother scaling. In short, multi-parameter sensors are a cornerstone of modern bioreactor control, improving both operational efficiency and product quality.

Why is it crucial to detect volatile compounds early in cultivated meat production?

Detecting volatile compounds early in cultivated meat production plays a key role in maintaining real-time oversight of metabolic activity. This allows producers to spot potential contamination or process deviations promptly, ensuring both quality and safety are upheld throughout production.

Addressing issues early means producers can improve yields, safeguard product consistency, and cut down on waste - essential steps for efficiently scaling the production of cultivated meat.