What’s the better choice for cultivated meat production: single-use or reusable equipment? It depends on your production scale and financial priorities. Single-use systems are cheaper upfront, quicker to set up, and easier to maintain, but they generate recurring costs for consumables and create plastic waste. Reusable systems cost far more initially and require complex infrastructure for cleaning and sterilisation but are more cost-effective over time, especially for large-scale operations.

Key Points:

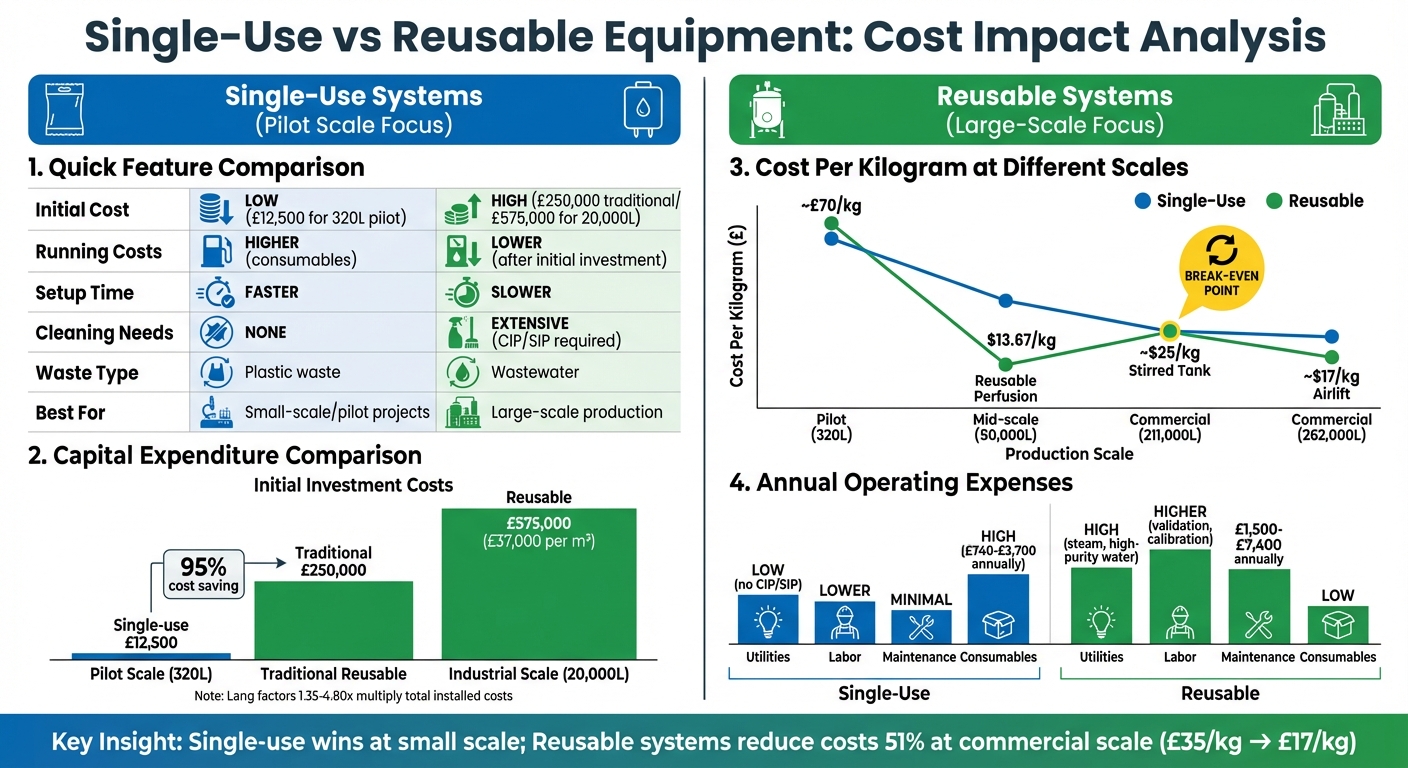

- Single-use systems: Lower initial costs, no cleaning requirements, faster setup, but higher consumables costs and plastic waste.

- Reusable systems: Higher upfront costs, cleaning expenses, but better long-term savings for high production volumes.

- At small scales, single-use systems are often more economical. For larger scales, reusable systems reduce costs per kilogram significantly.

Quick Comparison:

| Feature | Single-Use | Reusable |

|---|---|---|

| Initial Cost | Low | High |

| Running Costs | Higher (consumables) | Lower (after initial investment) |

| Setup Time | Faster | Slower |

| Cleaning Needs | None | Extensive |

| Waste | Plastic waste | Wastewater |

| Best For | Small-scale or pilot projects | Large-scale production |

Bottom line: Single-use is ideal for small, flexible operations. Reusable systems are better for scaling up and achieving lower costs per kilogram in the long run.

Single-Use vs Reusable Equipment Cost Comparison for Cultivated Meat Production

Capital Expenditure: Comparing Initial Investment Costs

Single-Use Equipment: Lower Upfront Investment

Single-use technology offers a clear advantage when it comes to reducing initial capital expenses. By eliminating the need for decontamination tools like CIP and SIP systems, manufacturers can sidestep the hefty costs tied to permanent sterilisation piping and intricate cleaning setups [6][5]. Instead, pre-sterilised plastic liners and closed systems simplify operations, reducing the need for extensive cleanroom infrastructure. This means facilities can be set up more quickly and with less financial strain [6].

This cost-saving approach is especially appealing to smaller enterprises or those partnering with contract manufacturers. Single-use facilities not only get up and running faster but also minimise cross-contamination risks and avoid the expense of lengthy validation processes [6]. These lower upfront costs provide a stark contrast to the heavier investment demands of reusable systems.

Reusable Equipment: Higher Initial Investment

Reusable systems, on the other hand, come with a much steeper initial price tag. Their construction relies on high-grade stainless steel, designed to endure repeated sterilisation cycles [7][8]. For example, a single 20 m³ (20,000-litre) food-grade bioreactor can cost around £575,000 ($778,000), with a base unit price of approximately £37,000 per m³ ($50,000) [8]. On top of this, permanent CIP/SIP systems add further costs due to the complexity of the required piping networks.

To understand the full cost, Lang factors - which range from 1.35 to 4.80 [8] - are used to estimate that the total installed cost can be two to four times the base price. However, recent developments are beginning to disrupt these traditional cost structures. In May 2025, London-based Meatly introduced a 320-litre bioreactor for just £12,500, a dramatic reduction compared to the £250,000 typically needed for similar biopharma equipment - representing a 95% cost saving [4].

CapEx Comparison Table: Single-Use vs Reusable Systems

| Equipment Type | Initial Investment Level | Key Cost Drivers | Infrastructure Requirements |

|---|---|---|---|

| Single-Use | Low | Pre-sterilised plastic liners, sensors | Minimal (no CIP/SIP needed) |

| Reusable (Traditional) | High | Stainless steel alloys, permanent piping | Extensive (CIP/SIP, steam systems) |

| In-House/Food-Grade | Moderate | Custom engineering, biocompatible materials | Variable |

Further comparisons at different scales highlight the cost differences:

| Scale | Traditional Biopharma Cost | Low-Cost/In-House Cost |

|---|---|---|

| Pilot (320L) | £250,000 [4] | £12,500 [4] |

| Industrial (20,000L) | £575,000 [8] | Projected 95% lower per unit [4] |

These disparities in upfront costs play a crucial role in shaping the long-term financial outcomes of these systems.

sbb-itb-ffee270

Operational Expenditure: Ongoing Costs and Running Expenses

Single-Use Systems: Lower Running Costs

Single-use systems significantly cut everyday expenses by doing away with cleaning and sterilisation processes. Without Clean-in-Place (CIP) and Steam-in-Place (SIP) cycles, facilities save on water, chemicals, and energy costs [5][9]. Additionally, pre-sterilised disposable components reduce the need for cleaning and speed up turnaround times [5].

Labour costs, which are a major expense in cultivated meat production, are also reduced with single-use systems. These systems require less labour for tasks like cleaning, sensor calibration, and managing contamination risks [9]. This streamlined approach not only lowers costs but also minimises the likelihood of costly batch failures, making single-use systems particularly appealing for smaller-scale operations.

However, single-use systems come with a recurring cost: consumables. Items like disposable bioreactor bags and liners must be purchased for every production run. For smaller operations, these consumables can cost between £740 and £3,700 annually (about $1,000 to $5,000) [9]. Additionally, the plastic waste generated by these systems poses a challenge, as proper disposal is necessary to manage the environmental impact [5].

Reusable Systems: Higher Running Costs

Reusable systems, on the other hand, involve higher operational costs. While they require a substantial initial investment, their ongoing expenses also add up significantly. Stainless steel systems, for instance, demand intensive cleaning and sterilisation, which means high consumption of energy and high-purity water. Processes like reverse osmosis, ultrafiltration, and deionisation further increase these costs [9].

Labour is another key factor driving up costs. Reusable systems need regular maintenance, inspections, and cleaning validation [9]. Annual maintenance expenses for these systems typically range from £1,500 to £7,400 (approximately $2,000 to $10,000), depending on their complexity [9]. While energy-efficient components like variable frequency drives (VFDs) can help reduce electricity use, the overall energy consumption remains significantly higher than that of single-use systems [9].

Wastewater management also adds to the costs. Cleaning wastewater, which often contains biological residues, requires expensive nutrient treatment processes [3].

Annual OpEx Comparison Table

| Cost Category | Single-Use Systems | Reusable Systems |

|---|---|---|

| Utilities (Water/Energy) | Low (no CIP/SIP required) | High (steam generation, high-purity water) |

| Labour Requirements | Lower (minimal cleaning/maintenance) | Higher (cleaning validation, sensor calibration) |

| Maintenance | Minimal | £1,500–£7,400 annually [9] |

| Consumables | High (recurring bag/liner purchases) | Low (primarily replacement parts) |

| Waste Management | Solid plastic disposal | Wastewater treatment |

| Contamination Risk | Lower (pre-sterilised components) | Higher (requires rigorous protocols) |

Total Cost of Ownership: Long-Term Cost Analysis

Break-Even Analysis at Different Production Scales

The financial outlook changes significantly as production volumes grow. For smaller-scale operations, single-use equipment often proves more economical due to its lower upfront costs. However, as production scales up, reusable systems start to offer better value despite their higher initial investment.

For instance, a custom 320-litre bioreactor costs around £12,500, whereas a traditional biopharma-grade reusable reactor of the same capacity comes in at £250,000 - a massive 95% cost reduction with a custom food-grade design [4][12]. At a commercial scale, switching from a 42,000-litre stirred-tank bioreactor to a 262,000-litre airlift reactor can cut costs from $35/kg to $17/kg, representing a 51% reduction [3].

Another key consideration is waste management. As production scales up, the waste profiles of single-use and reusable systems diverge. Single-use setups generate significant plastic waste, which could lead to rising regulatory fees. On the other hand, reusable systems primarily incur stable wastewater treatment costs [5]. These shifting cost dynamics highlight the importance of exploring innovations like continuous vs fed-batch culture to improve efficiency further.

How Continuous Culture Affects Reusable Equipment Costs

Continuous manufacturing, particularly through perfusion technology, enhances the cost efficiency of reusable systems. Unlike batch processes that require frequent emptying and restarting, continuous culture allows extended production cycles with multiple harvests over more than 20 days. This method can sustain cell densities of up to 130 million cells per millilitre [10].

This approach maximises the utilisation of high-cost infrastructure. For example, in a 50,000-litre facility, perfusion technology can bring the cost of cultivated chicken down to approximately $6.2 per pound ($13.67/kg) [10]. Studies confirm that continuous manufacturing significantly lowers costs for scaling up cultivated meat production [10]. By optimising output, this method helps offset the higher initial costs of stainless steel equipment at commercial scales. These efficiency gains have a direct impact on long-term ownership costs, as shown in the table below.

TCO Comparison Table Across Production Volumes

| Production Scale | Equipment Type | Estimated Cost (£/kg or $/kg) | Cost Driver |

|---|---|---|---|

| Pilot (320 litres) | Custom Low-Cost | ~£70/kg [13] | Low CapEx, High Media Cost |

| Mid-scale (50,000 litres) | Reusable (Perfusion) | ~$13.67/kg [10] | High Yield, Continuous Harvest |

| Commercial (211,000 litres) | Reusable (Stirred Tank) | ~$25/kg [3] | Mechanical Complexity |

| Commercial (262,000 litres) | Reusable (Airlift) | ~$17/kg [3] | Economies of Scale, Depreciation |

This table highlights how scaling up production fundamentally alters cost dynamics. Single-use systems are suitable for pilot projects, but reusable equipment - especially when paired with continuous culture - becomes indispensable for achieving cost efficiency at commercial levels [10][5].

How Specialised Procurement Platforms Reduce Supply Chain Costs

Streamlined Equipment Sourcing

Specialised procurement platforms simplify the sourcing process for essential components like cell lines, culture media, scaffolds, and bioreactors used in cultivated meat production [11]. By consolidating these elements into a centralised system, they eliminate the hassle of dealing with multiple fragmented suppliers. More importantly, they shift the focus from expensive biopharma-grade equipment to more affordable food-grade alternatives [8, 23].

Take bioreactors as an example. A food-grade bioreactor costs about $50,000 per m³ (roughly £40,000 per m³), whereas pharmaceutical-grade systems come with a much heftier price tag [14, 23]. To put this into perspective, scaling up production to replace even 1% of the U.S. beef market could require anywhere from 50 to 5,205 bioreactors, depending on the technology used [8].

Culture media sourcing is another area where these platforms make a big impact. By bringing multiple vendors into a single marketplace, they reduce the administrative workload and help producers cut costs on expensive components like FGF‑2 and TGF‑β [14, 23]. This centralised approach not only lowers costs but also fosters transparency in pricing and helps build stronger, more reliable supplier relationships.

Transparent Pricing and Verified Suppliers

In addition to streamlining sourcing, transparent pricing is a key factor in reducing costs for cultivated meat production. With clear cost breakdowns for crucial components - like bioreactors, culture media, and labour, which together account for more than 80% of total production costs [2] - producers can better plan their infrastructure investments and avoid wasting resources on inefficient systems. This transparency directly supports long-term savings, as highlighted in total cost of ownership analyses.

Platforms like Cellbase (https://cellbase.com) enhance these benefits by offering access to verified suppliers. Transparent pricing combined with GMP-compliant vendors reduces risks tied to batch contamination, a critical issue in scaling production. For example, therapeutic stem cell manufacturers have turned to single-use bioreactor systems to minimise the financial fallout of contaminated batches [11, 14]. Verified suppliers help mitigate these risks, ensuring smoother operations as production scales up.

Conclusion: Choosing the Right Equipment for Your Production Scale

When Single-Use Equipment Makes Financial Sense

Single-use systems are particularly advantageous for pilot-scale production and early-stage facilities. With lower initial costs and minimal infrastructure needs, they allow startups to set up operations quickly and efficiently [1]. These systems also help reduce energy and water usage, making them a practical choice for producers managing flexible schedules or multi-product operations, all while eliminating the risk of cross-contamination [1]. However, as production scales up, the benefits of single-use systems can diminish, paving the way for reusable options to take centre stage.

When Reusable Equipment Delivers Better Value

For large-scale commercial production, reusable stainless-steel systems are the go-to choice. At this scale, they significantly reduce production costs - from around £28/kg to £14/kg [3]. While the upfront investment is higher, the long-term operational savings quickly balance out the initial expense [8]. Reusable systems are especially effective in continuous or semi-continuous culture modes, which maximise reactor output and lower per-unit costs. This efficiency is crucial for achieving price competitiveness with traditional meat [8].

Recommendations for Cultivated Meat Producers

A balanced approach often works best for cultivated meat producers. Opting for single-use systems during seed trains and early-stage cell expansion minimises contamination risks. Transitioning to large-scale reusable bioreactors for the final production phase then helps capture economies of scale [8]. Accurate cost modelling is critical, as bioreactors, culture media, and labour contribute to more than 80% of total production costs in large-scale facilities [2]. Tools like Cellbase (https://cellbase.com) offer transparent pricing and verified suppliers, helping producers make well-informed decisions and optimise their equipment mix to align with their production needs and financial goals.

Cost drivers of cultivated meat production

FAQs

What are the environmental considerations of using single-use versus reusable equipment in cultivated meat production?

Single-use equipment, like disposable bioreactors and tubing, can significantly cut down on energy, water, and chemical use since they don't require cleaning or sterilisation. This reduction translates to lower operational emissions, especially in facilities that rely on renewable energy sources.

But there's a catch. Most single-use systems are made from plastics, which means they generate waste and contribute to greenhouse gas emissions during both their production and disposal. On the other hand, reusable stainless-steel equipment starts with a bigger environmental footprint because of its manufacturing process. However, over time, this can be offset if the equipment is reused efficiently and cleaned using renewable energy-powered systems.

The environmental impact of each option isn’t straightforward - it hinges on factors like the energy source used, how waste is managed, and the efficiency of cleaning processes. This makes it clear that a balanced and thoughtful approach is crucial for minimising the environmental footprint of cultivated meat production.

How does production scale influence the choice between single-use and reusable equipment?

Production scale plays a big part in choosing between single-use and reusable systems for cultivated meat production. At smaller scales - like pilot projects or early commercial stages - single-use bioreactors are often the go-to option. Why? They come with lower upfront costs and eliminate the need for cleaning and validation. This saves both time and labour. Plus, they use less energy and water, making them a practical choice for start-ups and small to medium-sized enterprises (SMEs).

But when production ramps up to tens of thousands of litres, reusable systems start to make more financial sense. Although stainless-steel equipment requires a bigger initial investment, the long-term costs per kilogram of cultivated meat drop. This is thanks to lower consumable costs and the benefits of economies of scale. For instance, facilities producing over 100 million kilograms of cultivated meat annually often find reusable systems more economical.

A lot of companies take a mixed approach. They begin with single-use systems for their flexibility and cost advantages, then switch to reusable systems as production volumes increase. To make this transition smoother, Cellbase offers a carefully selected range of both single-use and reusable equipment. This allows businesses to choose tools that fit their current production needs while keeping future growth in mind.

What are the cost benefits of using continuous culture with reusable systems?

Continuous culture in reusable systems plays a key role in cutting costs for cultivated meat production. For instance, it can bring the cost of growth media down to about £0.52 per litre, which in turn reduces the production cost of cultivated chicken to roughly £5.10 per pound.

This approach offers a more cost-effective alternative to traditional batch processes, particularly when aiming to scale production efficiently.