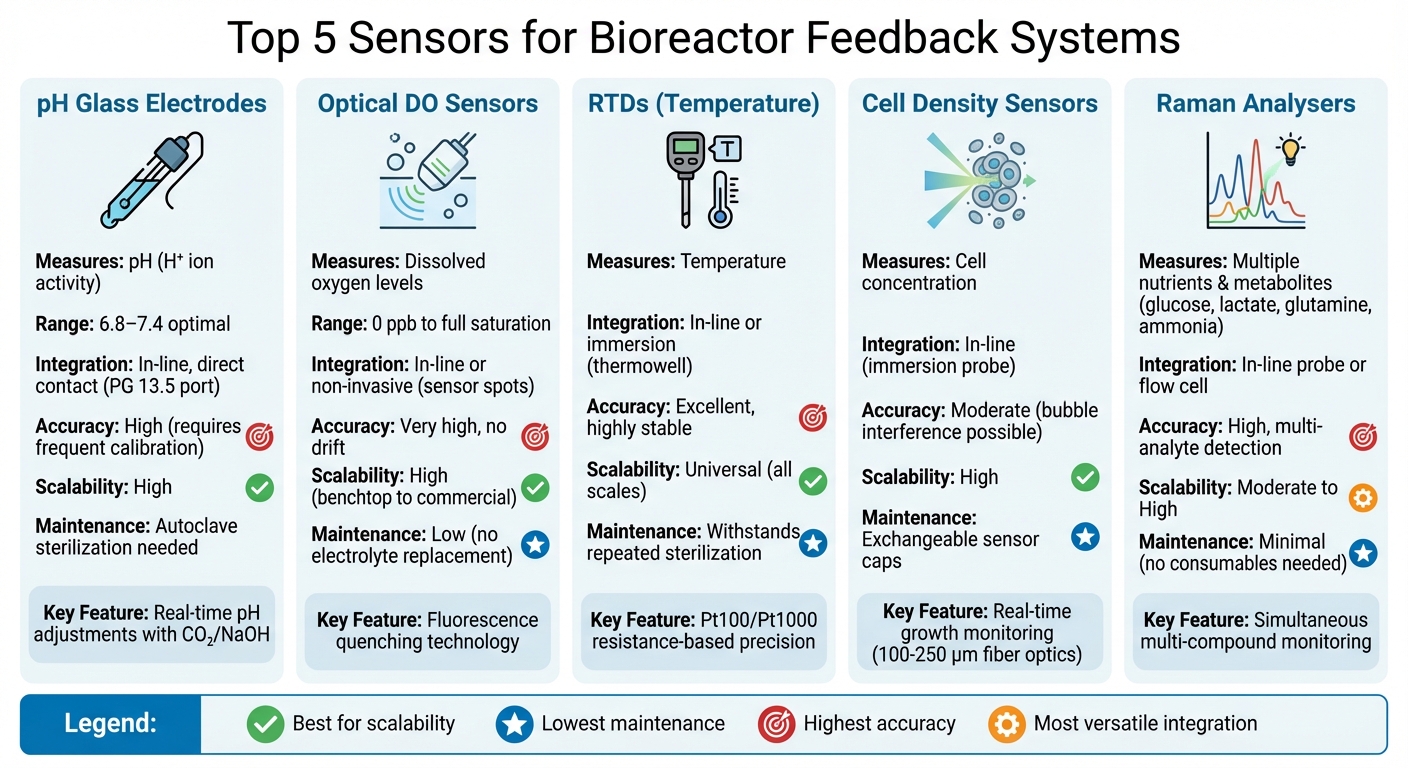

Maintaining precise conditions in bioreactors is critical for cultivated meat production. Sensors play a key role in monitoring and adjusting parameters like pH, dissolved oxygen (DO), temperature, cell density, and nutrient levels. Here's a quick overview of five sensor types that ensure consistent and compliant production:

- pH Glass Electrodes: Monitor pH levels in real-time to adjust acidity or alkalinity, keeping cells in the optimal range of 6.8–7.4.

- Optical DO Sensors: Measure oxygen levels using fluorescence quenching, ensuring accurate and reliable readings without interference.

- Resistance Temperature Detectors (RTDs): Provide precise temperature control, crucial for stable cell metabolism.

- Cell density and Raman sensors: Track cell concentration in real-time, aiding in consistent batch quality.

- Raman Analysers: Monitor multiple nutrients and metabolites simultaneously, enabling fine-tuned process control.

Each sensor type offers specific benefits for scaling from lab research to commercial production. Below is a quick comparison to help you choose the right sensor for your bioreactor setup.

Bioreactor Sensor Comparison: pH, DO, RTD, Cell Density and Raman Analyzers

Sensors in bioreactors

Quick Comparison

| Sensor Type | Measures | Integration | Accuracy | Scalability |

|---|---|---|---|---|

| pH Glass Electrodes | pH (H⁺ ion activity) | In-line, direct contact | High, needs calibration | High |

| Optical DO Sensors | Dissolved oxygen levels | In-line or non-invasive | Very high, no drift | High |

| RTDs | Temperature | In-line or immersion | Excellent, stable | Universal |

| Cell Density Sensors | Cell concentration | In-line | Moderate, bubble issues | High |

| Raman Analysers | Nutrients & metabolites | In-line or flow cell | High, multi-analyte | Moderate to High |

These sensors are integral to maintaining optimal conditions, minimising risks, and ensuring regulatory compliance in cultivated meat production. Proper integration and maintenance are key to leveraging their full potential. This is often managed through bioprocess control software to ensure data-driven decision-making.

1. pH Glass Electrodes (e.g., Memosens CPS61E)

pH glass electrodes are the go-to tool in cultivated meat production, ensuring the pH stays within the narrow range of 7.0–7.4 - vital for keeping cells alive and thriving. As lactate builds up and causes acidification, constant pH monitoring becomes essential[3].

Measurement Accuracy

These electrodes provide real-time feedback, allowing for instant pH adjustments. If the pH needs lowering, CO₂ is added; if it needs raising, NaOH is introduced. This precise control keeps the environment perfect for cell growth and differentiation into muscle fibres[3]. Marie-Laure Collignon, Senior Bioprocess Application Scientist at Cytiva, explains:

"The addition of air, CO₂, or basic solution is automatically managed by a controller that compares signal measure by the pH probe inserted in the bioreactor with the defined setpoint for the process."[3]

This level of precision ensures smooth integration with in-line monitoring systems.

Integration Method (In-line)

Unlike optical sensors, pH electrodes are inserted directly into the bioreactor. They come into contact with the culture medium, collecting data for batch reports and quality control purposes[4].

Scalability for Production

pH electrodes are effective across different scales, from lab research to full-scale commercial production[1]. However, as Gernot Thomas John, Director of Marketing and Innovation at PreSens Precision Sensing GmbH, points out:

"In many culture environments and vessel formats, application of electrodes would be very cumbersome or impossible. Too many electrodes disturb the flow pattern of some vessels... or are simply difficult to integrate because of a lack of space."[4]

Even with these challenges, their reliability makes them a staple for culture control in both research and manufacturing, playing a key role in scaling cultivated meat production from the lab to commercial operations.

Ease of Maintenance

Maintaining pH electrodes involves autoclave sterilisation and upkeep of the reference cell[4]. For single-use vs reusable bioreactors like stainless steel or glass systems, autoclavable dipping probes are crucial to ensure sterility. Following media sterility best practices is essential to prevent contamination during these processes. Their ability to continuously log signals reduces the need for manual intervention and helps meet regulatory standards[1].

2. Optical Dissolved Oxygen Sensors (e.g., Memosens COS81E)

Optical dissolved oxygen (DO) sensors play a vital role in cultivated meat production by ensuring that oxygen levels are carefully controlled. This is crucial because oxygen directly affects cell growth and viability, making its regulation just as important as managing pH levels. Unlike traditional electrochemical probes, these sensors rely on fluorescence quenching - a process where a light-sensitive dye emits fluorescence that is reduced in the presence of oxygen. This method allows for precise, non-invasive oxygen measurements [4][5].

Measurement Accuracy

Optical DO sensors use advanced digital signal processing systems, such as Memosens or ISM, to convert optical signals into reliable digital outputs. This technology resists interference from moisture and electromagnetic fields, ensuring accurate readings. These sensors can measure oxygen levels across a broad range, from 0 ppb to full saturation, and some models feature microsensors with tips as small as 50 µm, allowing for highly detailed measurements [4][5].

In larger bioreactors, gas bubbles can stick to the sensor tip, potentially distorting readings. To address this, advanced sensors are designed with hydrophilic and tilted surfaces that repel bubbles. According to Mettler Toledo:

"Optical DO sensors with a special OptoCap repel purge bubbles that collect and adhere to the tip of the DO sensor, eliminating the noise caused by purge bubbles and improving DO control" [5].

Additionally, these sensors come equipped with predictive diagnostics to monitor key factors like membrane stress and sterilisation cycles, ensuring consistent performance batch after batch.

Integration Method (In-line/Non-invasive)

Optical sensors offer flexible deployment options to suit different production needs. In-line probes, typically encased in stainless steel, are designed to fit standard bioreactor ports. They deliver real-time data, enabling automated control of aeration and agitation - an essential feature for large-scale operations [5]. Alternatively, non-invasive sensor spots can be embedded into cultivation bags and measured through the vessel's transparent walls. These spots are gamma-irradiated for sterility, reducing contamination risks by preserving the sterile barrier [4].

Gernot Thomas John, Director of Marketing and Innovation at PreSens Precision Sensing GmbH, highlights their convenience:

"The greatest advantage of using optical sensors is that they can be applied for remote sensing. The sensing component (the actual sensor) and the electro-optical components for sensor read-out (the transmitter) do not have to be in direct contact." [4]

This adaptability makes them effective across various production setups.

Scalability for Production

One of the standout features of optical DO sensors is their ability to scale across different production stages. The same sensor model can be used in everything from small benchtop bioreactors to large industrial vessels. As METTLER TOLEDO explains:

"The same sensor model can be used in all bioreactor sizes, from benchtop bioreactors to large-scale bioreactors in commercial phase manufacturing" [5].

With digital integration, these sensors store calibration data directly in the sensor head, enabling a 'Plug and Measure' setup. This reduces installation time and simplifies operations [5].

Ease of Maintenance

Optical sensors are designed to be low-maintenance compared to traditional electrochemical sensors. They don’t require frequent replacement of electrolytes or membranes, nor do they need the lengthy polarisation period (6–12 hours) that Clark-type sensors typically demand [5]. Built to withstand harsh environments, they can endure repeated autoclave and Steam-In-Place (SIP) cycles. Predictive diagnostics further simplify maintenance by tracking cleaning cycles and assessing sensor health before production begins.

3. Resistance Temperature Detectors (RTDs, e.g., TrustSens TM371)

Maintaining precise temperature control is a cornerstone of cultivated meat production. Even minor temperature fluctuations can disrupt cellular metabolism and compromise product quality [7][4]. Alongside pH and dissolved oxygen, temperature is a key parameter for ensuring stable and efficient bioprocesses. Resistance Temperature Detectors (RTDs), such as the TrustSens TM371, provide accurate, real-time temperature monitoring, which is essential for maintaining optimal conditions in bioreactors.

Measurement Accuracy

RTDs are known for their precision, thanks to their durable construction and sanitary connectors, which minimise variability between production batches [7]. Advanced RTD models come equipped with online calibration features, addressing calibration drift without halting production [8]. This capability is increasingly important as modern bioprocessing demands dependable sensor performance [6]. Additionally, technologies like digital sensor management (e.g., ISM) improve data transparency and provide insights into sensor lifespan [7].

Integration Method (In-line)

RTDs are integrated directly into bioreactors using dipping probes connected to steel tubes or port adapters, delivering continuous, real-time data for immediate temperature adjustments [4][7][6]. For single-use bioreactors, RTDs can be welded into polymer bags or installed using specialised housings and connectors [7]. This flexibility ensures compatibility with both traditional and single-use systems, while digital integration simplifies calibration across different production scales [7].

Scalability for Production

RTDs are designed to scale effortlessly, from small benchtop bioreactors to industrial vessels with capacities of 10,000 to 20,000 litres. This ensures consistent environmental conditions for cells, regardless of the vessel size [6][7]. Whether used in stainless steel bioreactors or modern single-use systems, RTDs adapt seamlessly when paired with the right housings [7].

Ease of Maintenance

Unlike some next-generation biosensors, which may struggle with stability in complex bioreactor environments, RTDs offer reliable performance [8][6]. They are built to withstand repeated sterilisation cycles, ensuring uninterrupted monitoring and integrating quality control into the manufacturing process [1]. Automated monitoring systems further enhance their usability, reducing the need for manual checks and providing detailed documentation to meet regulatory requirements.

sbb-itb-ffee270

4. Absorption-Based Cell Density Sensors (e.g., OUSBT66)

Keeping track of cell density in real-time is a cornerstone of cultivated meat production. By understanding how cells grow and behave during the proliferation and differentiation stages, producers can maintain consistency across batches. Absorption-based sensors, like the OUSBT66, make this possible by measuring cell concentration through changes in light intensity as it passes through the culture medium [2]. This method provides continuous, real-time data without the delays or contamination risks that come with manual sampling [2][4].

Measurement Accuracy

The OUSBT66 sensor is specifically designed to capture spatial changes in cell density, making it a valuable tool for detailed Process Analytical Technology (PAT) frameworks [2][6]. Unlike other methods, these sensors don’t consume analytes or suffer from electromagnetic interference, which helps minimise signal noise [2][4]. This level of accuracy is crucial for monitoring live-cell health throughout the cultivation process, ensuring consistent results from batch to batch [1]. Additionally, the use of optical fibres - ranging from 100 to 250 μm in diameter - allows for compact and flexible probe designs [2]. This precision makes it easier to integrate these sensors into automated monitoring systems.

Integration Method (In-line)

Absorption-based sensors are designed for in-line integration, maintaining sterility throughout production [4]. Their dipping probes are particularly useful in stainless steel bioreactors, where opaque walls make non-invasive sensing impossible. Autoclavable versions can handle the rigorous cleaning and sterilisation cycles required in commercial production, while sealed ports ensure sterility is maintained [4]. By measuring directly within the system, these sensors eliminate errors linked to manual sampling [4]. This in-line integration is key to sustaining reliable performance as production scales up.

Scalability for Production

These sensors are built with scalability in mind, ensuring they can adapt to various production environments [1][4]. Whether in small-scale R&D setups or industrial bioreactors holding over 1,000 litres, absorption-based sensors perform consistently [1][4]. The same optical sensing technology works seamlessly in both single-use polymer bags and large stainless steel vessels [2][4]. This adaptability ensures that cultivated meat producers can maintain effective monitoring as they move from research to full-scale manufacturing. Additionally, automated data logging supports the detailed documentation needed for regulatory compliance [1].

Ease of Maintenance

Switching from electrochemical to optical sensing offers a major advantage: reduced maintenance. Unlike electrochemical probes, which need frequent calibration and are prone to signal drift and fouling, absorption-based sensors provide long-term stability with minimal upkeep [2]. Many models are equipped with exchangeable sensor caps, making routine maintenance simple without compromising sterility. For single-use applications, pre-irradiated sensors integrated into culture bags eliminate the need for on-site sterilisation [4]. This reliability aligns perfectly with the automated systems discussed earlier, cutting down on manual interventions and ensuring smoother operations.

5. Raman Analysers for Metabolite and Nutrient Tracking

Raman spectroscopy offers a powerful way to monitor multiple metabolites and nutrients at the same time. By creating a detailed molecular fingerprint, it identifies important compounds like glucose, lactate, glutamine, and ammonia in real time [9]. This capability is especially useful in cultivated meat production, where maintaining precise nutrient levels is essential for ensuring proper cell growth, differentiation, and the quality of the final product. It works alongside other real-time sensors - such as those for pH, dissolved oxygen (DO), temperature, and cell density - to improve process control in this emerging field.

Measurement Accuracy

Raman analysers are known for their precision, achieved through predictive chemometric modelling techniques like Partial Least Squares or Principal Component Analysis. These methods help extract meaningful data from complex spectral information [9]. For example, a 2018 study showed that in-line Raman spectroscopy could accurately monitor nutrient consumption and metabolite production in a stirred tank bioreactor, thanks to these modelling techniques [9]. The technology offers high chemical specificity with minimal interference from water, making it ideal for bioprocessing applications [9].

Integration Method (In-line/Non-invasive)

Raman analysers can be integrated into processes in two main ways: as in-line immersion probes that are placed directly in the culture medium, or as non-invasive flow cells used in perfusion systems [9]. The flow cell method has a distinct advantage - it measures the cell-free harvest stream, avoiding issues like light scattering caused by high cell densities. One study demonstrated how a HyperFluxPRO Raman spectrometer was integrated into a perfusion process, enabling automated glucose feed control across various bioreactor scales with minimal prediction error [10]. This kind of in-line integration delivers immediate feedback on performance while maintaining sterility.

Scalability for Production

One of the great strengths of Raman spectroscopy is its ability to scale effortlessly. Bench-scale models can be applied directly to production-scale bioreactors without major recalibration, significantly reducing production costs [10]. This scalability is a game-changer for cultivated meat producers moving from research to commercial manufacturing. Just like other sensors, Raman analysers contribute to the consistency and efficiency of bioreactor operations, making them a key part of closed-loop feedback systems in this industry.

Ease of Maintenance

Raman analysers are practically maintenance-free, which is a major advantage for long-duration processes. They don’t require consumables or frequent calibration, even during extended cultivation periods [10]. This reliability helps reduce the need for manual intervention, lowering the risk of contamination and ensuring a more stable process overall - critical factors in cultivated meat production.

For producers aiming to optimise their processes, platforms like Cellbase provide access to a range of high-quality sensors, including Raman analysers, which play a crucial role in improving production efficiency.

Sensor Comparison Table

Here’s a handy table outlining the key performance features of various sensors, making it easier to choose the right one for your bioreactor feedback system.

| Sensor Type | Measurement Principle | Integration Method | Accuracy Range | Production Scalability |

|---|---|---|---|---|

| pH Glass Electrode | Potentiometric (H⁺ ion activity) | Standard PG 13.5 port; housing required | High (but needs frequent calibration) | High; widely used in stainless steel setups |

| Optical DO Sensor | Fluorescence quenching | PG 13.5 port or single-use spot | Very High; no drift due to oxygen consumption | High; performs well in long-duration runs |

| RTD (Temperature) | Resistance change (Pt100/Pt1000) | Thermowell or direct immersion | Excellent; highly stable | Universal; suitable for all production scales |

| Absorption (Cell Density) | Light attenuation/NIR | In-line flow cell or immersion probe | Moderate; prone to issues like bubbles or fouling | High; crucial for harvest timing |

| Raman Analyser | Inelastic light scattering | Optical probe via standard port | High; capable of multi-analyte detection | Moderate to High; higher upfront costs |

This table offers a concise way to evaluate which sensor best fits your bioreactor's needs, whether you’re scaling up or optimising processes. For cultivated meat producers, Cellbase provides access to a carefully curated range of these sensors tailored to your specific bioprocessing requirements.

Conclusion

Selecting sensors for cultivated meat bioreactors is essential to maintaining the precise conditions needed for cultivated meat production. Even small deviations can impact growth rates, disrupt metabolic processes, or even lead to culture failure. The five sensor types discussed - pH electrodes, optical dissolved oxygen sensors, RTDs, absorption-based cell density monitors, and Raman analysers - are key to ensuring effective process control.

Advancements in optical sensing are reshaping how processes are monitored. These sensors allow for real-time, in situ data collection without interfering with the cultures, minimising contamination risks and supporting extended production cycles [4]. Their ability to provide accurate data while being minimally invasive makes them a game-changer.

However, proper integration is just as critical as sensor selection in closed-loop feedback systems. Sensors must be robust enough to handle sterilisation and resist fouling, all while automatically logging data to meet compliance requirements. Optical fibre sensors, with tips as small as 50 µm, provide a level of precision and low invasiveness that traditional electrochemical probes cannot achieve [4].

For producers looking to adopt these technologies, platforms like Cellbase offer a streamlined approach. They provide access to verified sensors and complete monitoring systems, along with expert guidance on integration and calibration. This ensures that your sensors align with regulatory standards and meet the specific demands of your bioprocessing workflows [1]. With the right sensor technology in place, you can maintain critical parameters seamlessly from research stages to full-scale production.

FAQs

What should I consider when selecting sensors for my bioreactor?

When choosing sensors for your bioreactor, it’s essential to prioritise the specific parameters you need to monitor, like pH, dissolved oxygen, or metabolites. Make sure the sensors you select are fully compatible with your bioreactor system and can deliver real-time, in situ measurements without disturbing the culture environment.

Take optical fibre sensors and chemical optical sensors as examples - they’re known for their precision and their ability to minimise interference during the process. Additionally, automated systems that combine data logging with process control can improve both reliability and adherence to industry standards.

The key is to select sensors that meet your monitoring requirements, provide reliable data, and are suited to the specific challenges of cultivated meat production.

What maintenance is required for bioreactor sensors?

To maintain accuracy and reliability, bioreactor sensors used in cultivated meat production need regular attention, including calibration and cleaning. Calibration should be carried out at set intervals using standard reference solutions, as outlined in the manufacturer's instructions. This ensures that measurements within the bioreactor's controlled environment remain precise.

Routine cleaning and sterilisation are equally important to avoid fouling or contamination. These steps not only help meet regulatory requirements but also play a key role in delivering consistent product quality. Single-use sensors often simplify maintenance, as they eliminate the need for extensive care. On the other hand, reusable sensors demand more effort, such as checking connections, replacing any worn-out parts, and storing them correctly to maximise their lifespan and performance.

Are bioreactor sensors suitable for scaling from lab research to commercial cultivated meat production?

Bioreactor sensors are designed to transition smoothly from laboratory research to large-scale commercial production of cultivated meat. Many commonly used sensors, like optical pH and dissolved oxygen (pO2) sensors, are standard across both small-scale and industrial bioreactors. These tools offer non-invasive, real-time monitoring, ensuring consistent and precise data collection at any scale.

Recent advancements in sensor technology, such as in-line and microfluidic sensors, have made scaling up more efficient. These innovations help reduce costs and improve process control during production. Moreover, manufacturers are prioritising easy integration of these sensors into larger systems while preserving their reliability and accuracy. This approach ensures they meet the growing needs of commercial cultivated meat production effectively.